Long-acting quality-guaranteeing composite microbial agent and preparation method thereof

A compound microbial agent and long-acting technology, which is applied in aquaculture, microbial agent, ecological planting, and agricultural microbiology, can solve the problems of short storage period, inconspicuous fertilizer effect, single strain of microbial agent, etc. Oxygen, the effect of reducing the amount of chemical fertilizers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

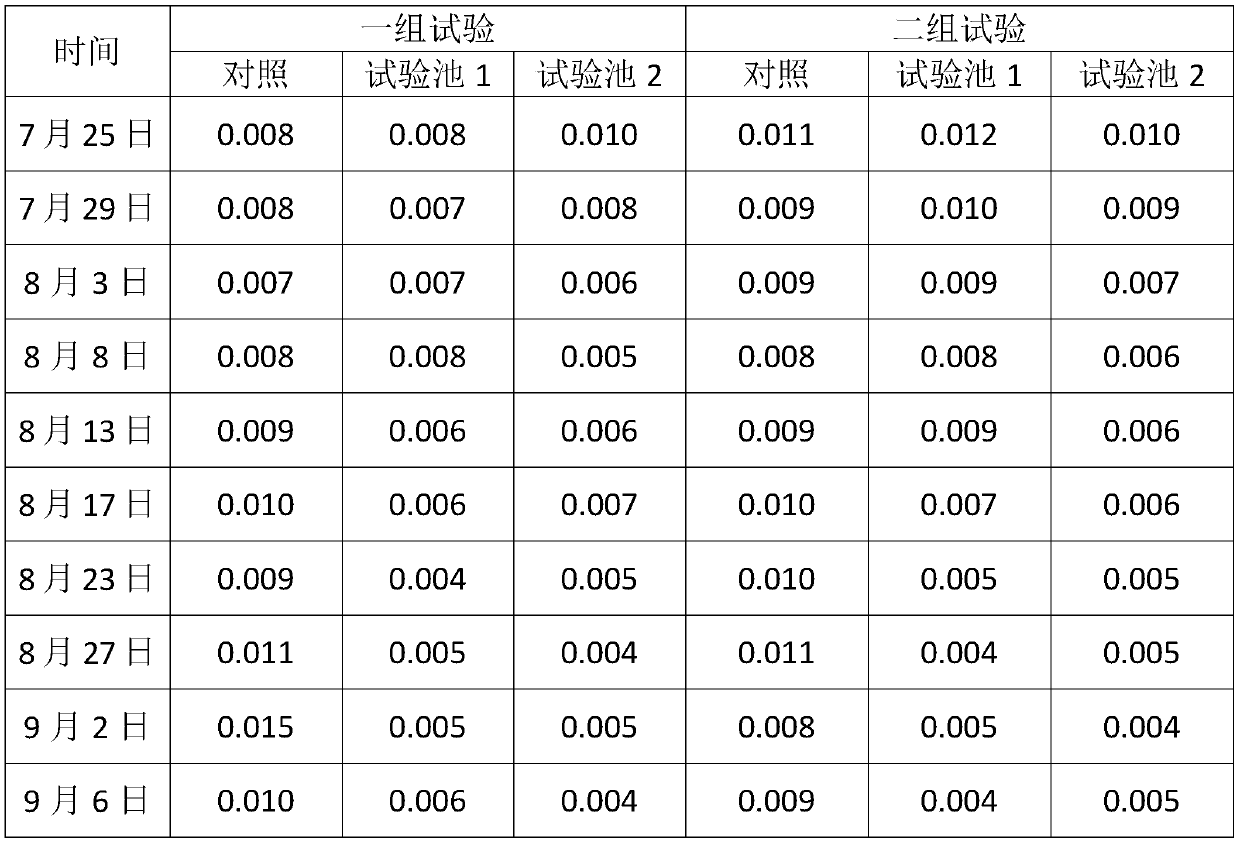

Examples

preparation example Construction

[0040] A preparation method for a long-term quality-preserving compound microbial bacterial agent, comprising the following steps:

[0041] 1. 4 kinds of aerobic bacteria Bacillus colloidus, Streptomyces flavinus, Bacillus subtilis and Bacillus amyloliquefaciens were respectively cultivated to make 4 kinds of liquid aerobic bacteria agents,

[0042] (1) Prepare the liquid aerobic culture medium of Bacillus colloidus, Streptomyces flavinus, Bacillus subtilis and Bacillus amyloliquefaciens respectively, and then inoculate respective corresponding strains in 4 kinds of liquid aerobic culture medium respectively, Under the conditions of 33-37°C, 100-140r / min, and pH value of 6.0-7.5, the primary expansion culture of the strains was carried out to obtain 5 kinds of primary aerobic bacterial liquids;

[0043] (2) Take 4 kinds of first-level aerobic bacteria liquids and inoculate the respective corresponding strains into the 4 kinds of liquid aerobic culture mediums, and carry out th...

Embodiment 1

[0061] Composite microbial bacterial agent comprises 4 kinds of liquid aerobic bacterial agents cultivated with liquid medium and 4 kinds of liquid anaerobic bacterial agents cultivated with liquid medium, and the mass ratio of liquid aerobic bacterial agent and liquid anaerobic bacterial agent is 2: 3.

[0062] Liquid aerobic bacterial agent is made up of the bacterial agent of following mass parts:

[0063] 2 parts by mass of the liquid Streptomyces luteus agent; 3 parts by mass of the liquid Bacillus subtilis agent; 2 parts by mass of the liquid Bacillus amyloliquefaciens agent; 3 parts by mass of the liquid Bacillus subtilis agent.

[0064] Liquid anaerobic bacterial agent is made up of the bacterial agent of following mass parts:

[0065] 3 parts by mass of liquid photosynthetic bacteria; 2 parts by mass of liquid Saccharomyces cerevisiae inoculum; 5 parts by mass of liquid plant milk inoculum; 5 parts by mass of liquid Lactobacillus acidophilus inoculum.

[0066] Where...

Embodiment 2

[0089] Composite microbial bacterial agent comprises 4 kinds of liquid aerobic bacterial agents cultivated with liquid medium and 4 kinds of liquid anaerobic bacterial agents cultivated with liquid medium, and the mass ratio of liquid aerobic bacterial agent and liquid anaerobic bacterial agent is 10: 11.

[0090] Liquid aerobic bacterial agent is made up of the bacterial agent of following mass parts:

[0091] 1 part by mass of liquid Streptomyces flavinus agent; 3 parts by mass of liquid Bacillus subtilis agent; 3 parts of liquid Bacillus amyloliquefaciens; 3 parts by mass of liquid Bacillus subtilis agent.

[0092] Liquid anaerobic bacterial agent is made up of the bacterial agent of following mass parts:

[0093] 2 parts by mass of liquid photosynthetic bacteria; 3 parts by mass of liquid Saccharomyces cerevisiae inoculant; 3 parts by mass of liquid plant milk inoculum; 3 parts by mass of liquid Lactobacillus acidophilus agent.

[0094] Wherein, each kind of liquid aerob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com