Fat extract, fat acellular matrix and preparation method and application of fat acellular matrix

A technology of acellular matrix and extraction liquid, applied in the field of fat acellular matrix and its preparation, and fat extraction liquid, can solve the problems of increasing operation difficulty and biological pollution, and achieve the advantages of shortening processing time, avoiding damage and high biological safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

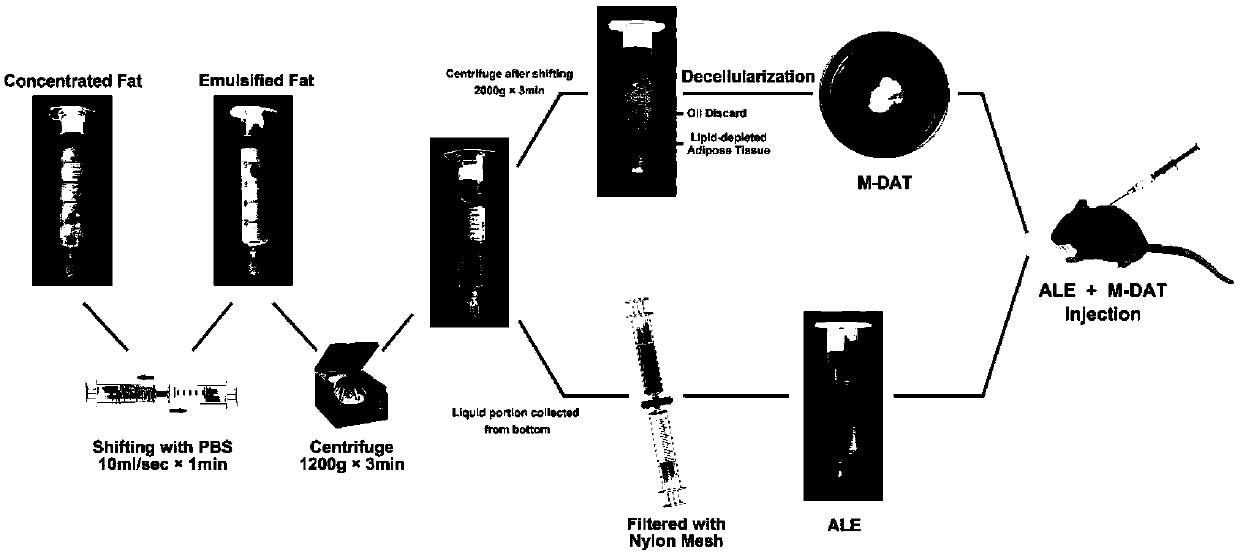

[0043] Example 1: Preparation of fat extract (Adipose liquid extract, ALE) and fat decellularized matrix M-DAT (Mechanical processing DAT: DAT prepared by physical method)

[0044]1) Wash the obtained granular fat with phosphate buffered saline (PBS), centrifuge at 1000g / min for 3min, discard the upper layer of fat and the bottom layer of liquid after centrifugation, and collect the middle layer of adipose tissue.

[0045] 2) The adipose tissue obtained in step 1) was mixed with an equal volume of PBS, and transferred to a 10 ml screw syringe.

[0046] 3) Connect the fat-containing syringe obtained in step 2) with a new 10ml screw syringe through a 2.4mm caliber Luer connector, push the fat-containing syringe piston, and push the fat into the contralateral syringe, The bolus injection speed is 10ml / s, so that the back-and-forth bolus injection is continued for 1min.

[0047] 4) Centrifuge the bolus product obtained in step 3) at 2000g / min for 5min, discard the upper layer of ...

Embodiment 2

[0055] Example 2: Preparation of fat extract ALE and fat decellularized matrix M-DAT

[0056] 1) Wash the obtained fat particles with buffered saline (PBS), centrifuge at 800g / min for 2min, discard the upper layer of fat and bottom liquid after centrifugation, and collect the middle layer of adipose tissue.

[0057] 2) The adipose tissue obtained in step 1) was mixed with an equal volume of PBS, and transferred to a 10 ml screw syringe.

[0058] 3) Connect the fat-containing syringe obtained in step 2) with a new 10ml screw syringe through a 1.4mm caliber Luer connector, push the fat-containing syringe piston, and push the fat into the contralateral syringe, The bolus injection speed is 8ml / s, so continuous back and forth bolus injection for 0.5min.

[0059] 4) Centrifuge the bolus product obtained in step 3) at 1500g / min for 3 minutes, discard the upper layer of fat, collect the bottom liquid part as ALE and store it at -20°C for later use, and deoil the middle layer after b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com