Waterproof, sun-proof and heat-insulating building material protection brick and preparation method thereof

A protection and cement technology, applied in the field of building materials, can solve the problems of short service life of thermal insulation bricks, heavy and damaged cement prefabricated boards, etc., and achieve the effects of good thermal insulation performance, good load-bearing performance, and increased comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

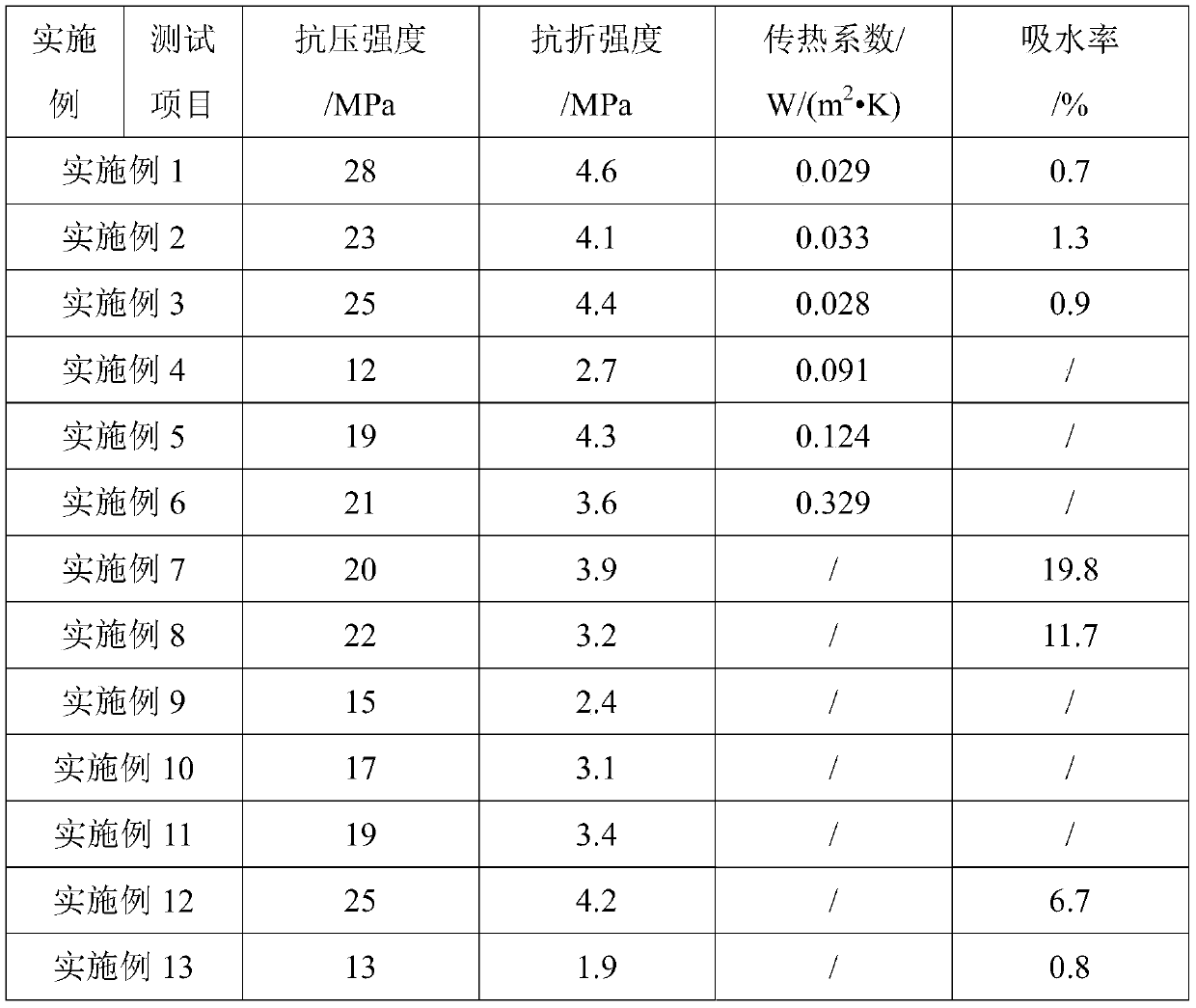

Examples

preparation example Construction

[0048] The preparation method of the acrylic emulsion includes at least the following steps:

[0049] (1) Add acrylic acid, butyl acrylate, catalyst, and polymerization inhibitor into the reactor, heat to 80-100°C, add glycidyl amine epoxy resin dropwise at a rate of 2-8 drops / min, and stir continuously, Carry out ring-opening condensation reaction to obtain epoxy acrylate;

[0050] (2) Cool the epoxy acrylate to 65-75°C, add trihydroxy polyether, rosin alcohol, and initiator, stir and react for 6-8 hours, then add N-methylpyrrolidone, stir and dilute for 10 minutes, then add lignin sulfonate Disperse calcium acid and water ultrasonically for 20 minutes to obtain acrylic emulsion.

[0051] Preferably, the preparation method of the acrylic emulsion is:

[0052] (1) According to parts by weight, add 100 parts of acrylic acid, 40 parts of butyl acrylate, 0.1 part of trimethylbenzyl ammonium chloride, and 0.1 part of hydroxyphenylmethane into the reactor, and heat it to 80°C with 3 drops...

Embodiment 1

[0116] Example 1 provides a waterproof, sun-proof, and heat-preserving building material anti-protection brick, which in parts by weight includes at least the following components: 40 parts of cement, 80 parts of heat insulation materials, 35 parts of acrylic emulsion, 14 parts of polyurethane emulsion, and 1 part of mold agent and 10 parts of filler.

[0117] The thickness of the protective brick is 15 cm.

[0118] The cement is Portland cement, purchased from Foshan Runhe Building Materials Co., Ltd., model: China Resources 325 Cement.

[0119] The heat insulation material is a combination of large ceramsite with a particle size of 20mm and small ceramsite with a particle size of 10mm, with a weight ratio of 4:1, and is purchased from Anhui Shengmao Ceramic Products Co., Ltd.

[0120] The preparation method of the acrylic emulsion is:

[0121] (1) According to parts by weight, add 100 parts of acrylic acid, 40 parts of butyl acrylate, 0.1 part of trimethylbenzyl ammonium chloride, an...

Embodiment 2

[0137] Example 2 provides a waterproof, sun-proof, and heat-preserving building material anti-protection brick, which, in parts by weight, at least includes the following components: 30 parts of cement, 70 parts of heat insulating materials, 25 parts of acrylic emulsion, 5 parts of polyurethane emulsion, and 0 parts of mold agent and 5 parts of filler.

[0138] The thickness of the protective brick is 15 cm.

[0139] The cement is Portland cement, which was purchased from Foshan Runhe Building Materials Co., Ltd., model China Resources 325 Cement.

[0140] The heat insulation material is a combination of large ceramsite with a particle size of 20 mm and small ceramsite with a particle size of 10 mm, with a weight ratio of 3:1, and is purchased from Anhui Shengmao Ceramic Products Co., Ltd.

[0141] The preparation method of the acrylic emulsion is:

[0142] (1) According to parts by weight, add 100 parts of acrylic acid, 40 parts of butyl acrylate, 0.1 part of trimethylbenzyl ammonium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com