Preparation method of hydroxyphenylboronic acid

A technology of hydroxybenzene boronic acid and boronic acid ester, applied in chemical instruments and methods, compounds containing periodic table Group 3/13 elements, production of bulk chemicals, etc. Competitiveness, high cost, easy protection and deprotection, easy industrial scale-up, and good process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

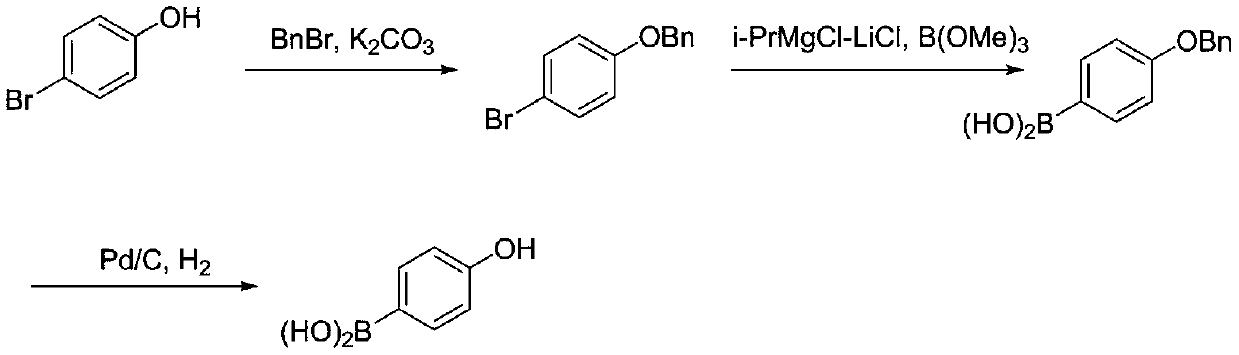

Embodiment 1

[0023]

[0024] In the reaction flask, add p-bromophenol (17.3g, 0.1mol), potassium carbonate (18.0g, 0.13mol), benzyl bromide (18.8g, 0.11mol) and dioxane 140mL, after stirring evenly, heat up to 40 React at -45°C for 10 hours. After detecting the completion of the reaction, evaporate the solvent to dryness, add water and ethyl acetate to separate layers, extract the aqueous layer twice with ethyl acetate, combine the organic layers and wash with saturated sodium chloride, dry over anhydrous magnesium sulfate, evaporate to dryness, and ethanol / heptane The mixed solvent was beaten to obtain 24.7 g of off-white solid, with a yield of 94%.

[0025] Under the protection of nitrogen, add 24.7g (0.094mol) of the above solid into 80mL of tetrahydrofuran, dissolve it completely under stirring, cool to -10°C to 0°C, and start to dropwise add 1.3M isopropylmagnesium chloride-lithium chloride / tetrahydrofuran solution (94mL , 0.122mol), the dropwise addition was completed, and the he...

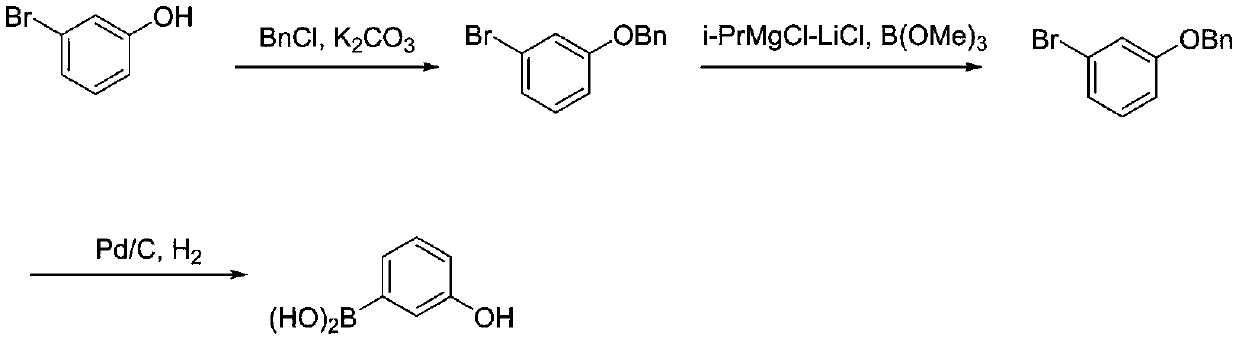

Embodiment 2

[0027]

[0028] In the reaction flask, add m-bromophenol (17.3g, 0.1mol), potassium carbonate (20.7g, 0.15mol), benzyl chloride (15.2g, 0.12mol) and dioxane 130mL, after stirring evenly, heat up to 40 React at -45°C for 10 hours. After detecting the completion of the reaction, evaporate the solvent to dryness, add water and ethyl acetate to separate layers, extract the aqueous layer twice with ethyl acetate, combine the organic layers and wash with saturated sodium chloride, dry over anhydrous magnesium sulfate, evaporate to dryness, and ethanol / heptane The mixed solvent was beaten to obtain 24.9 g of off-white solid, with a yield of 95%.

[0029] Under the protection of nitrogen, add 24.9 g (0.095 mol) of the above solid into 80 mL of tetrahydrofuran, dissolve it completely under stirring, cool to -10°C to 0°C, and start to dropwise add 1.3M isopropylmagnesium chloride-lithium chloride / tetrahydrofuran solution (94mL , 0.122mol), the dropwise addition was completed, and th...

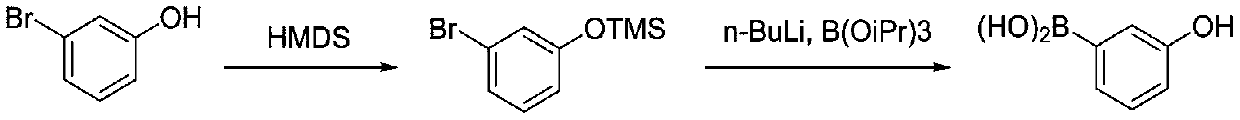

Embodiment 3

[0031]

[0032] In the reaction flask, m-bromophenol (17.3g, 0.1mol), ammonium chloride (0.3g) and 110mL of hexamethyldisilazane were added, stirred evenly, and heated to reflux for overnight reaction. After the completion of the detection reaction, the solvent was evaporated to dryness, and then the temperature was raised to 40-50° C. for 40 minutes under reduced pressure and vacuum pumping, and 24.6 g of oily liquid was obtained in the reaction bottle, with a yield of 100%.

[0033] Under the protection of nitrogen, the above oily liquid was added into 150 mL of tetrahydrofuran and dissolved completely under stirring, then triisopropyl borate (24.4 g, 0.13 mol) was added. Then it was cooled to -60°C, and 2.5M n-butyllithium hexane solution (44mL, 0.11mol) was added dropwise. After the dropwise addition was completed, the reaction was kept for 2 hours, and then the temperature was slowly raised to -10°C. After the detection reaction is completed, the temperature is controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com