Olefin polymerization catalyst carrier, preparation method and applications thereof

A catalyst carrier and olefin polymerization technology, which is applied in the field of olefin polymerization, can solve problems such as carrier adhesion, unstable preparation process, and poor carrier molding effect, and achieve high bulk density, good shape, and reduced adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] According to the first aspect of the present invention, the present invention provides a kind of preparation method of olefin polymerization catalyst carrier, and this preparation method comprises:

[0024] (1) mixing and emulsifying magnesium carboxylate, magnesium halide, alcohol compound, and an optional inert liquid medium to obtain an emulsified product;

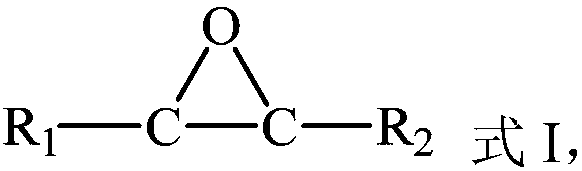

[0025] (2) contacting and reacting the emulsified product with an oxirane compound to obtain a solid-liquid mixture containing an olefin polymerization catalyst carrier.

[0026] In the present invention, the general formula of the magnesium halide is MgXY, wherein X is a halogen, Y is a halogen, C 1 -C 14 Alkyl, C 1 -C 14 Alkoxyl, C 6 -C 14 Aryl or C 6 -C 14 of aryloxy groups.

[0027] Preferably, in the general formula MgXY, X is chlorine or bromine, Y is chlorine, bromine, C 1 -C 5 Alkyl, C 1 -C 5 Alkoxyl, C 6 -C 10 Aryl or C 6 -C 10 of aryloxy groups.

[0028] In the present invention, C 1 -...

Embodiment 1

[0069] In a 0.6L reactor, add 8.0g (0.08mol) of magnesium chloride, 56mL (0.96mol) of ethanol, 2.1g of anhydrous magnesium acetate (0.015mol), raise the temperature to 80°C under stirring, react at constant temperature for 2 hours, and then add 38mL (0.48mol) of epichlorohydrin was reacted for 30 minutes and then press-filtered. The press-filtered product was washed 5 times with hexane, and finally the product was vacuum-dried to obtain the olefin polymerization catalyst carrier Z1.

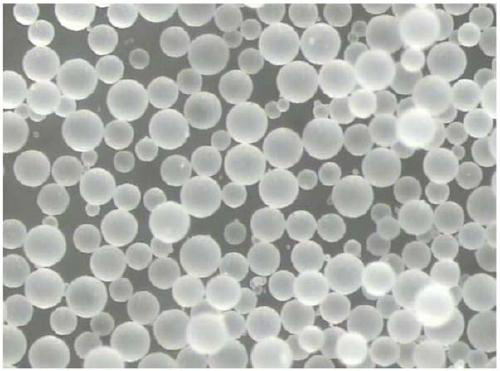

[0070] The average particle diameter (D50) of the olefin polymerization catalyst carrier Z1 was 51 μm, and the particle size distribution ((D90-D10) / D50) was 0.8. Particle morphology observed by optical microscopy, such as figure 1 As shown, the particle shape of the olefin polymerization catalyst carrier Z1 is relatively regular, the surface is smooth, basically spherical, the particle size distribution is relatively concentrated, and there are basically no abnormal particles.

Embodiment 2

[0072] In a 0.6L reaction kettle, add 300mL white oil, 8.0g (0.08mol) magnesium chloride, 28mL (0.48mol) ethanol, 1g anhydrous magnesium acetate (0.007mol), heat up to 100°C under stirring, and react at constant temperature for 1 hour , then add 12.5mL (0.16mol) epichlorohydrin, press filter after reacting for 20 minutes, wash the press filter product with hexane for 5 times, and finally vacuum dry the product to obtain olefin polymerization catalyst carrier Z2.

[0073] The average particle diameter (D50) of the olefin polymerization catalyst carrier Z2 was 48 μm, and the particle size distribution ((D90-D10) / D50) was 0.7. From the particle morphology observed by optical microscope, it can be seen that the particle shape of the olefin polymerization catalyst carrier Z2 is relatively regular, the surface is smooth, basically spherical, the particle size distribution is relatively concentrated, and there are basically no abnormal particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com