A kind of one-component polyurethane sealant and low temperature, fast preparation method

A polyurethane sealant, one-component technology, used in polyurea/polyurethane adhesives, adhesives, adhesive types, etc. Waste of resources and water resources and other issues, to achieve the effect of reducing equipment costs and labor costs, less reaction side reactions, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

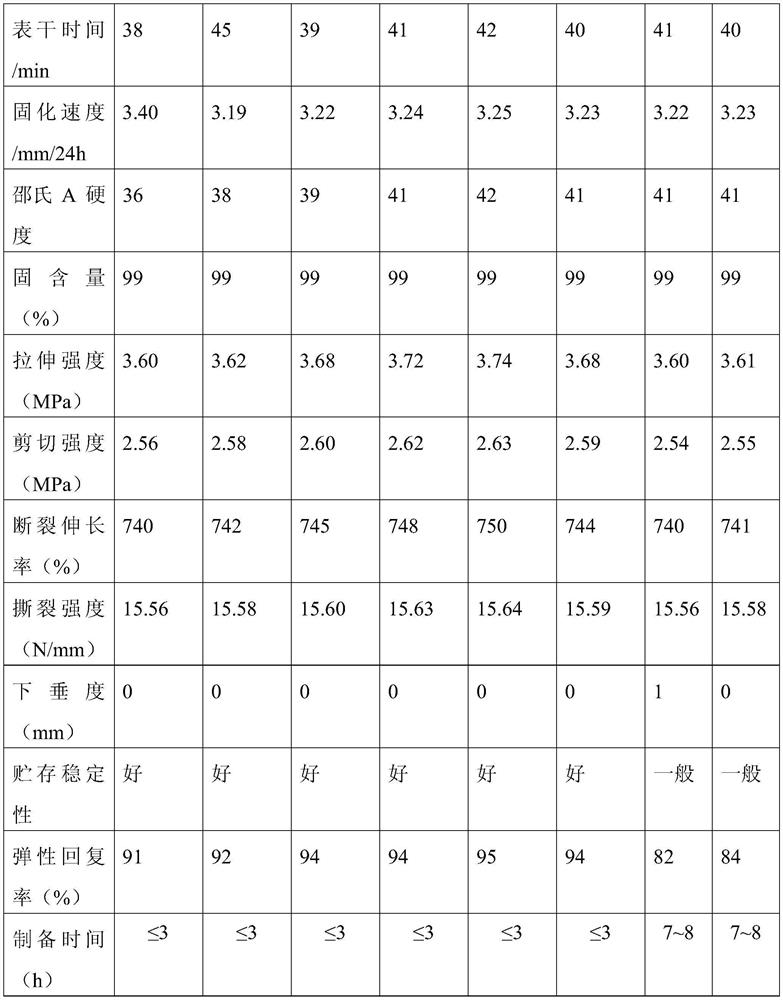

Examples

preparation example Construction

[0069] The present invention also includes the preparation method of one-component polyurethane sealant, comprises the following steps:

[0070] ①In parts by weight, add 15-30 parts of plasticizer to the reaction kettle, heat up to 60-100°C, add 15-55 parts of filler, 0.2-2 parts of water remover, 0.00001-0.002 parts of catalyst, stir 0.5 ~ 1 hour, stop heating to obtain a uniform paste, the viscosity of the paste is generally 0.4 × 10 6 ~8×10 6 mPa s;

[0071] ② Add 8-45 parts of polyol and 1-10 parts of polyisocyanate to the paste obtained in step ①, control the temperature at 45-80°C, stir for 0.5-1 hour, add 0.00001-0.02 parts of catalyst to it, the function aids 0 to 10 parts of agent, continue to stir and react for 10 to 30 minutes, and control the temperature at 45 to 60°C to obtain a single-component polyurethane sealant masterbatch with a viscosity of generally 0.4×10 6 ~8×10 6 mPa s;

[0072] ③Add the remaining parts by weight of the catalyst and the remaining p...

Embodiment 1

[0092] A one-component polyurethane sealant, consisting of the following raw materials: polyol 8kg, polyisocyanate 1kg, plasticizer 15kg, water remover 0.2kg, filler 15kg and catalyst 0.1kg;

[0093] Described polyol is polyether polyol;

[0094] Described polyisocyanate is diphenylmethane diisocyanate;

[0095] Described plasticizer is phenyl alkyl sulfonate;

[0096] The water removal agent is p-toluenesulfonyl isocyanate;

[0097] The filler is nanometer calcium carbonate;

[0098] The catalyst is dibutyltin dilaurate.

Embodiment 2

[0100] A one-component polyurethane sealant, consisting of the following raw materials: 45kg polyol, 10kg polyisocyanate, 30kg plasticizer, 2kg water remover, 55kg filler, 15kg functional additive and 1kg catalyst;

[0101] Described polyol is polyester polyol;

[0102] Described polyisocyanate is toluene diisocyanate;

[0103] Described plasticizer is didecyl phthalate;

[0104] Described dewatering agent is triethyl orthoformate;

[0105] The filler is carbon black;

[0106] The catalyst is N-ethylmorpholine;

[0107] The functional auxiliary agent is a thixotropic hydrophobic fumed silica.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com