Ultra-low temperature resistant and environmentally friendly two-component polyurethane adhesive and its preparation and application

A two-component polyurethane, environmentally friendly technology, used in polyurea/polyurethane adhesives, adhesives, non-polymer adhesive additives, etc., can solve the problems of slow curing speed, non-environmentally friendly solvents, and low peel strength , to achieve the effect of fast curing speed, improved peel strength, good hydrolysis resistance and low temperature peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

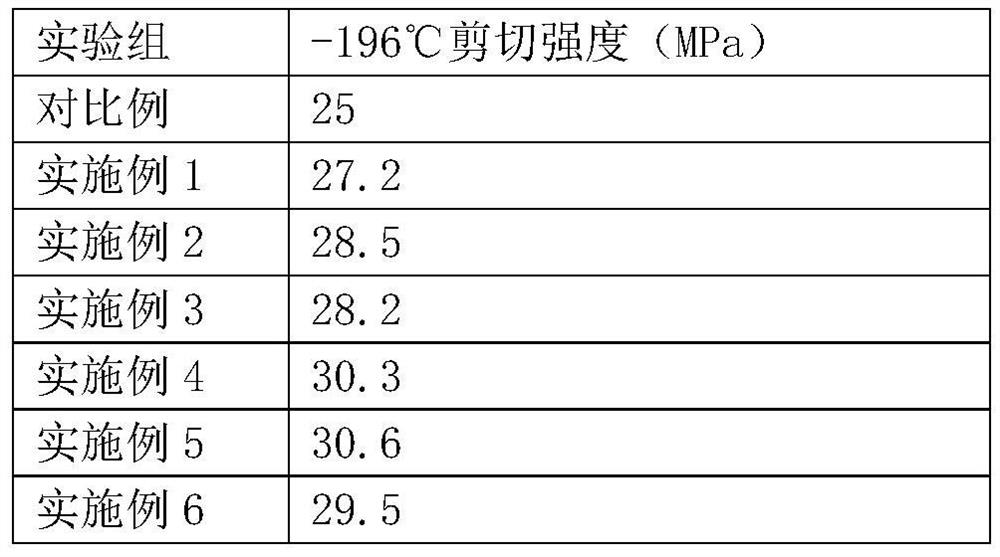

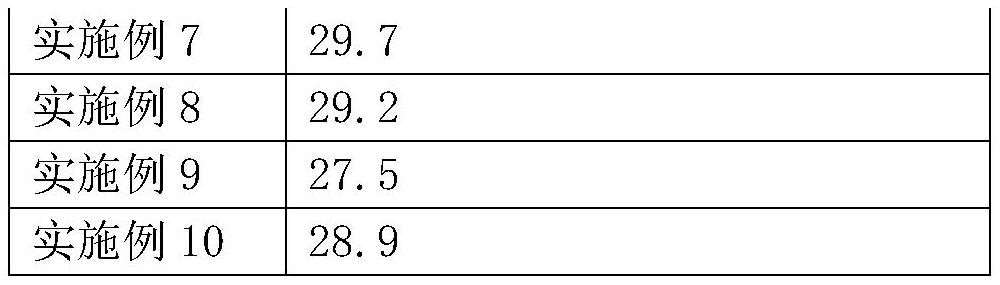

Examples

Embodiment 1

[0056] The A component includes a component of the weight percentage:

[0057] 40% of isocyanate (Wanhua MDI-100)

[0058] Polyether polyol (Dow Chemical 1000LM) 10%

[0059] Castor oil polyol (Japan Io oil H-30) 50%

[0060] The above A component was mixed and uniformly increased to 75 to 80 ° C for 3 h, evacuated and evacuated, and the cooling was removed, that is, the A-1 component was obtained.

[0061] The B component includes a component of the weight percentage:

[0062] Polycarbonate polyol (Damazu fine chemical PPC-2202P) 5%

[0063] Polytegahydrofuran polyol modification (INVISTA 3MCPG) 53.5%

[0064] Castor oil polyol (Japan Io oil H-30) 5%

[0065] Crosslinking agent (US Eastman TMPD) 3%

[0066] Catalyst (US leading chemistry Bicat 8108) 0.5%

[0067] Diven solidulator (British Incorez EH) 1%

[0068] Adhesion promoter (Hanjiang fine chemical JH-0187) 2%

[0069] Filler (Jiangxi Huaming nano calcium carbonate SPTL-2) 20%

[0070] Threulation agent (WACHEAGEA H20) 10%

...

Embodiment 2

[0074] The A component includes a component of the weight percentage:

[0075] 40% of isocyanate (Wanhua MDI-100)

[0076] Polyether polyol (Dow Chemical 1000LM) 40%

[0077] Castor oil polyol (Japan Io H-30) 20%

[0078] The above A component was mixed and uniformly increased to 75 to 80 ° C for 3 h, vacuum disproportionate, cooling the discharge, that is, the A-2 component was obtained.

[0079] The B component includes a component of the weight percentage:

[0080] Polycarbonate polyol (Damazu fine chemical PPC-2202P) 25%

[0081] Polytegahydrofuran polyol modification (INVISTA 3MCPG) 16.4%

[0082] Castor oil polyol (Japan Io oil H-30) 25%

[0083] Crosslinking agent (US Eastman TMPD) 5%

[0084] Catalyst (US leading chemistry Bicat 8108) 1%

[0085] Diven Correctant (British Incorez EH) 0.6%

[0086] Adhesion promoter (Hanjiang fine chemical JH-0187) 2%

[0087] Filler (Jiangxi Huaming Nano Calcium Carbonate SPTL-2) 15%

[0088] Threulation agent (WACHEAGEA H20) 10%

[0089] ...

Embodiment 3

[0092] The A component includes a component of the weight percentage:

[0093] Isocyanate (Wanhua MDI-100) 55%

[0094] Polyether polyol (Dow Chemical 1000LM) 10%

[0095] Castor oil polyol (Japan Io H-30) 35%

[0096] The above A component was mixed and homogeneously tapered to 75 to 80 ° C for 3 h, vacuum dispropted, and the cooling was removed, the A-3 component was obtained.

[0097] The B component includes a component of the weight percentage:

[0098] Polycarbonate polyol (Damazi fine chemical PPC-2202P) 40%

[0099] Polytegahydrofuran polyol modification (INVISTA 3MCPG) 7.4%

[0100] Castor oil polyol (Japan Io oil H-30) 30%

[0101] Crosslinking agent (US Eastman TMPD) 3%

[0102] Catalyst (US leading chemistry Bicat 8108) 1%

[0103] Diven Correctant (British Incorez EH) 0.6%

[0104] Attachment Accession (Hanjiang Fine Chemical JH-0187) 3%

[0105] Filler (Jiangxi Huaming nano calcium carbonate SPTL-2) 10%

[0106] Threulation agent (WACHOCIALATIVE H20) 5%

[0107] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com