Decompression and injection augmentation agent for water injection well of medium-low-permeability oilfield and preparation method thereof

A technology for oilfield water injection and booster injection, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as high water injection pressure and water injection volume that cannot meet the injection requirements, so as to reduce water injection pressure and improve effective injection. Permeability, the effect of reducing the thickness of the hydration film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In terms of mass, the surface treatment agent of the present embodiment: 40% of nonionic surfactant (fatty alcohol polyoxyethylene ether AEO-9), 15% of anionic surfactant (sodium α-olefin sulfonate), amphoteric surfactant Agent (cocamidopropyl betaine) 45%;

[0030] The preparation method of the pressure-reducing and injection-increasing agent for medium and low permeability oilfield water injection wells of the present invention is realized according to the following steps:

[0031] First, add 35g of the compounded surfactant into a 1000mL flask, add 400mL of deionized water and stir evenly, then raise the temperature to 75°C, and stir at constant temperature for 55 minutes. At this time, the solution turns from turbid to clear;

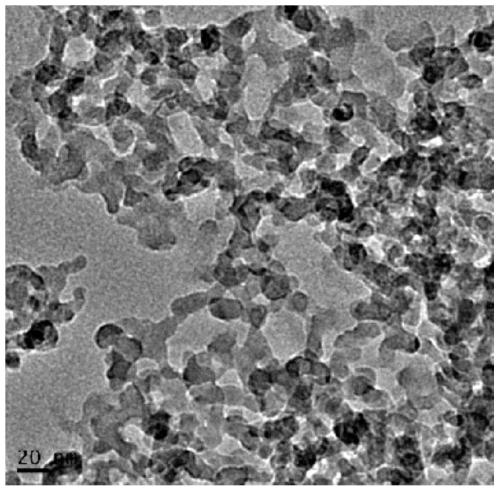

[0032] When the temperature drops below 40°C, add 15g of hydrophobic nano-silica, add 15% sodium hydroxide aqueous solution to control the pH value between 12, and finally add 300mL of deionized water and stir evenly, then slowly heat up, wai...

Embodiment 3

[0040] In terms of mass, the surface treatment agent of the present embodiment: 40% of nonionic surfactant (polyoxyethylene sorbitan fatty acid ester), 15% of anionic surfactant (sodium dodecylbenzenesulfonate), amphoteric surface active agent Active agent (tetradecyl amidopropyl hydroxypropyl sultaine) 45%;

[0041] The pH regulator of the present embodiment is 8% sodium carbonate aqueous solution in mass percent.

[0042] The preparation method of the pressure-reducing and injection-increasing agent for medium and low permeability oil field water injection wells of the present embodiment is realized according to the following steps:

[0043] First add 25g of the compounded surfactant into a 1000mL flask, add 300mL of deionized water and stir evenly, then raise the temperature to 75°C, and stir at constant temperature for 50 minutes. At this time, the solution turns from turbid to clear;

[0044] When the temperature drops below 55°C, add 30g of hydrophobic nano-silicon diox...

Embodiment 4

[0046] In terms of mass, the surface treatment agent of the present embodiment: 40% of nonionic surfactant (polyoxyethylene sorbitan fatty acid ester), 15% of anionic surfactant (sodium dodecylbenzenesulfonate), amphoteric surface active agent Active agent (tetradecyl amidopropyl hydroxypropyl sultaine) 45%;

[0047] The pH regulator of the present embodiment is 8% sodium carbonate aqueous solution in mass percent.

[0048] The preparation method of the pressure-reducing and injection-increasing agent for medium and low permeability oil field water injection wells of the present embodiment is realized according to the following steps:

[0049] First add 25g of the compounded surfactant into a 1000mL flask, add 300mL of deionized water and stir evenly, then raise the temperature to 75°C, and stir at constant temperature for 50 minutes. At this time, the solution turns from turbid to clear;

[0050] When the temperature drops below 55°C, add 30g of hydrophobic nano-polysilicon an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com