Ultrasonic quenching device and cracking quenching process

An ultrasonic and quenching technology, used in cracking, petroleum industry, non-catalytic thermal cracking, etc., can solve the problems of easy coking of cracking quenchers, affecting work efficiency, etc., to increase effective production time, prolong operation period, and increase economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0044] 1. Pilot test

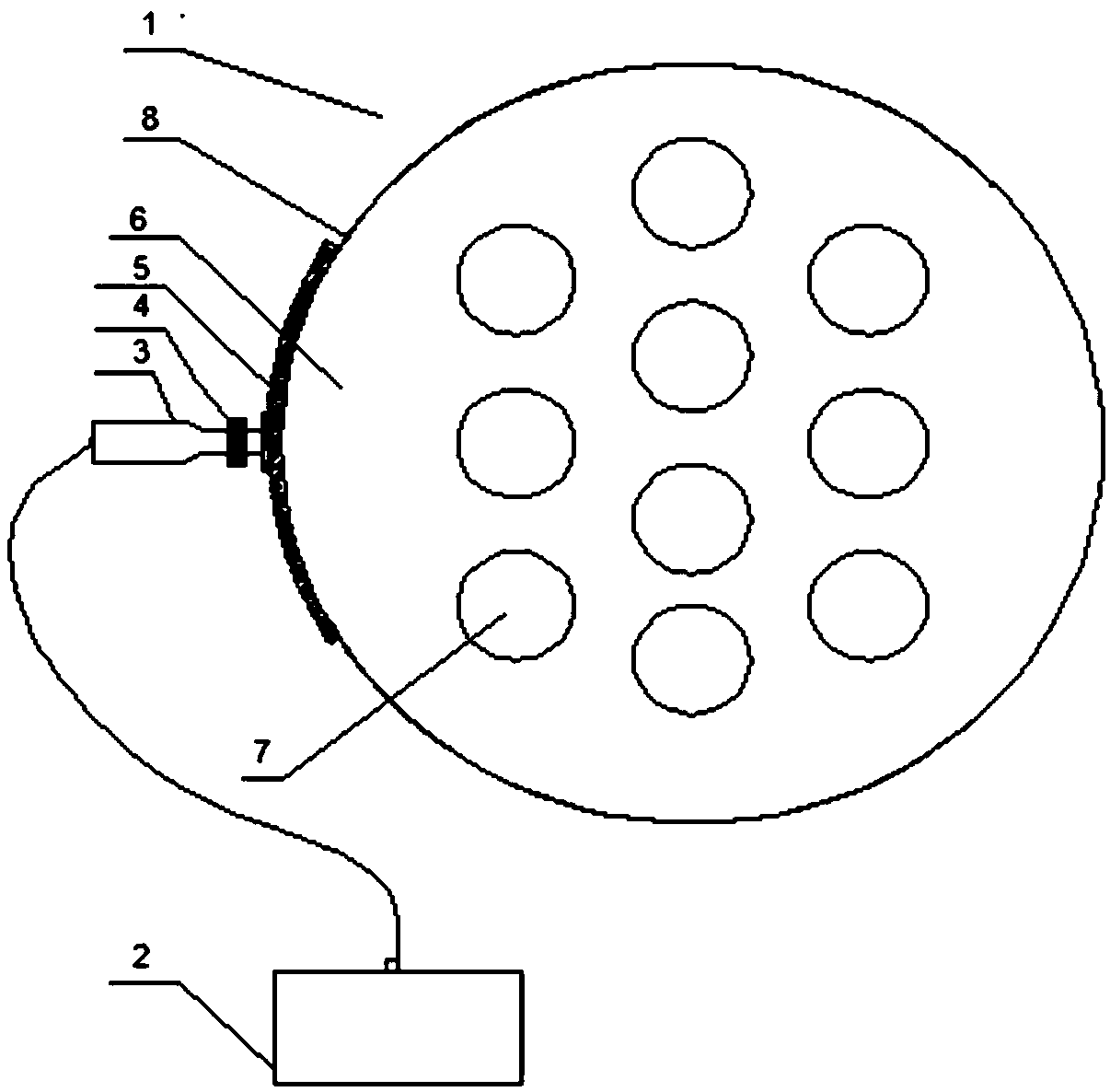

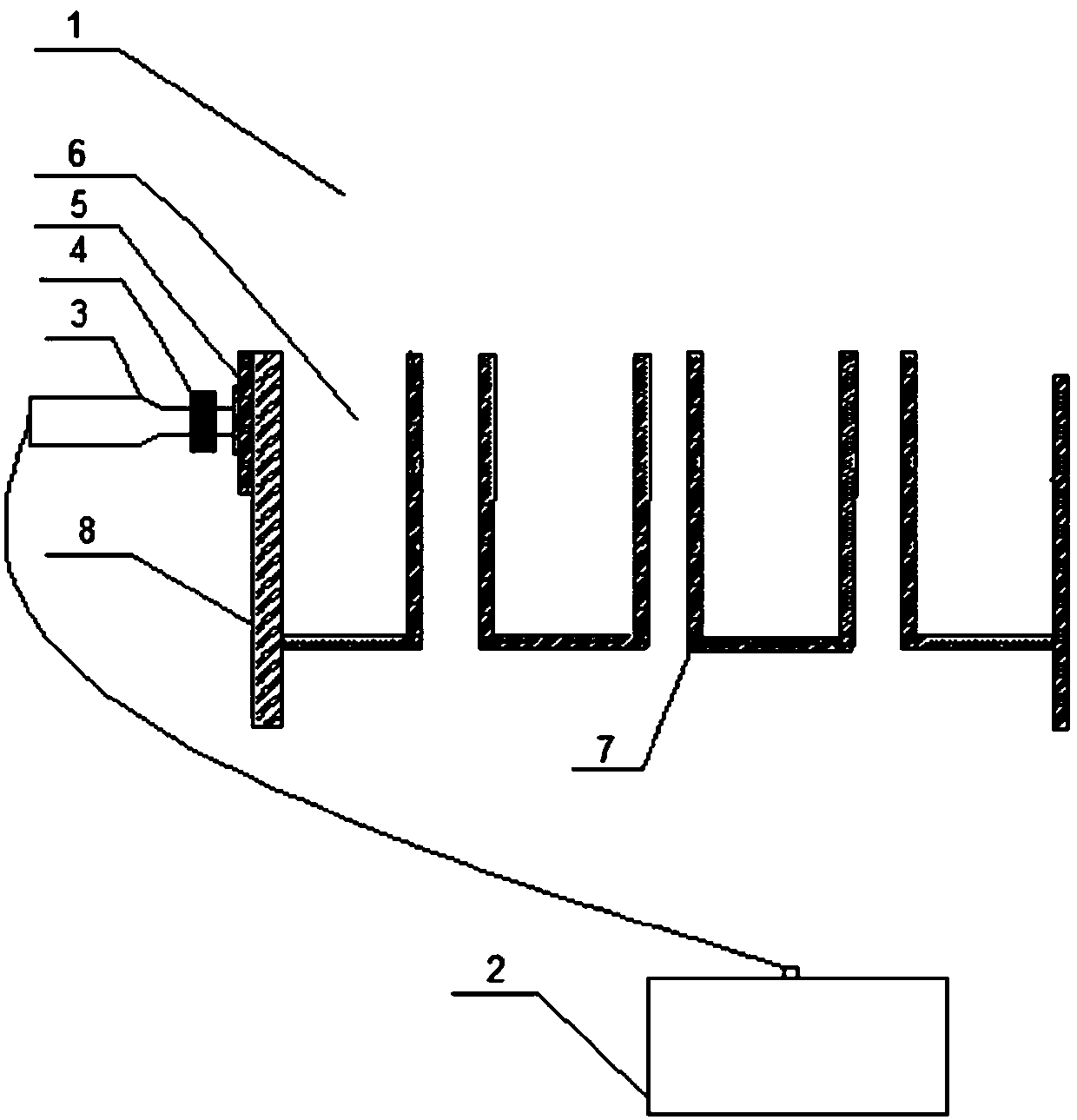

[0045] In order to compare the effect of the sparger, an experimental verification was carried out on a cracking pilot plant, and a certain liquid ethylene raw material was cracked, and the following methods were used: Figure 1-2 The ultrasonic quenching device of the present invention (experimental group 1), the ordinary quenching device without ultrasonic waves (blank group) and the ultrasonic quenching device without distributor (comparative group 1) were evaluated experimentally.

[0046] The test process conditions are: pyrolysis reaction temperature 820°C, dilution ratio 0.5, residence time 0.32s, blank group, comparison group 1 and comparison group 2 used the same material and size of the quencher, and comparison group 1 did not connect the distribution The transducer is directly connected to the shell side by means of flange compression; the sparger used in comparison group 2 is a carbon steel structure with a thickness of 5mm, the sparger is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com