Automobile sill beam aluminum alloy and preparation method thereof

A door sill beam and aluminum alloy technology, which is applied in the field of automobile door sill beam aluminum alloy and its preparation, can solve the problems that cannot be satisfied at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

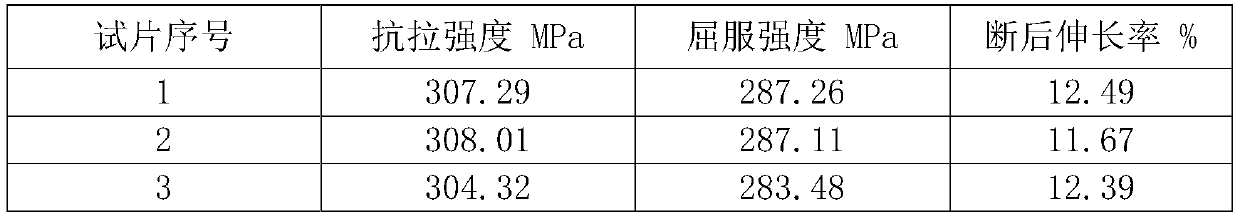

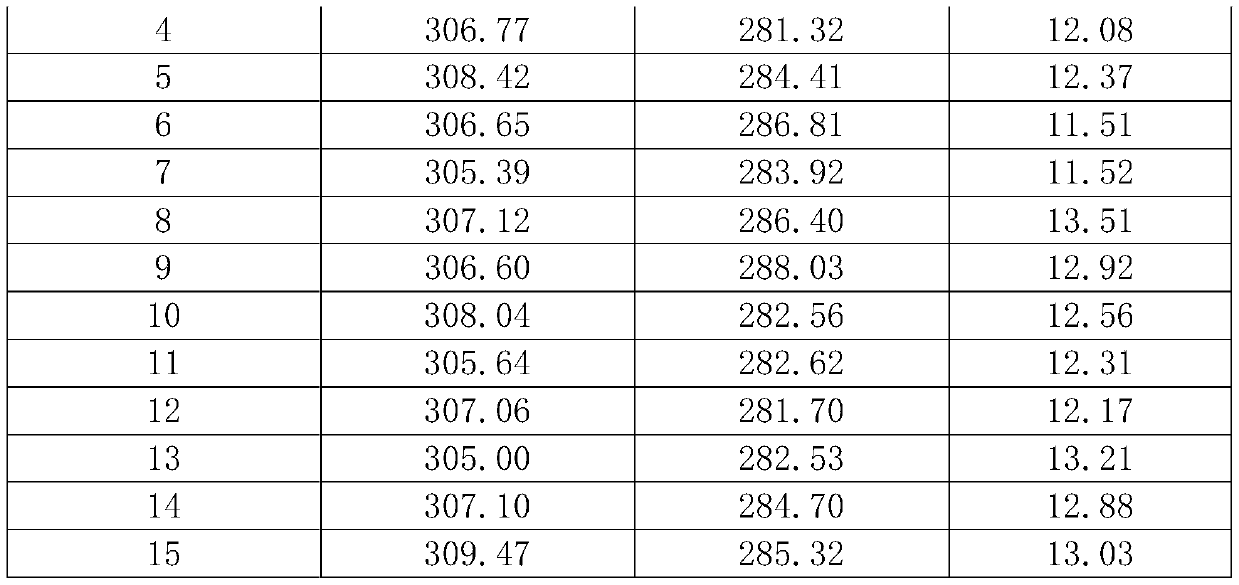

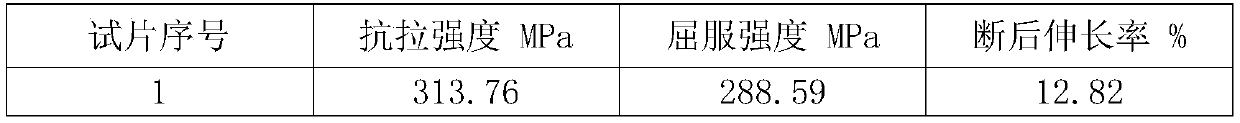

[0026] Example 1 Preparation of aluminum alloy for automobile door sill beam and its performance verification

[0027] Implementing equipment: 25T aluminum smelting furnace and its casting system, 40T homogenizing furnace, aluminum rod sawing machine, aluminum extrusion machine-2200T, aging electric furnace, milling machine, 20T universal testing machine.

[0028] Preparation steps:

[0029] (1) Smelting aluminum liquid, adding aluminum-copper alloy with copper content of 50wt%, aluminum-silicon alloy with silicon content of 20wt%, magnesium ingot of 99.9wt%, manganese agent with manganese content of 75wt%, during the smelting process, the temperature of aluminum liquid is 740 -760°C; in the final aluminum rod, the alloy content in mass percentage meets: magnesium 0.90-1.10wt%, silicon 0.90-1.10%, manganese 0.50-0.80%, copper 0.20-0.40%;

[0030] (2) The aluminum liquid adopts two-stage filtration, and the mesh numbers of the filter plates are 40 mesh and 60 mesh respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com