Method for controlling color of hard coating, hard coating and preparation method thereof

A hard coating and color technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve problems such as single coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The embodiment of the present invention also provides a preparation method of a hard coating,

[0058] Include the following steps:

[0059] Place the alloy target and substrate in a closed chamber;

[0060] Passing an inert gas into the chamber to make the interior of the chamber an oxygen-free inert atmosphere, vaporizing the alloy target in the oxygen-free inert atmosphere and forming an amorphous alloy layer on the substrate ;

[0061] Introduce first oxygen into the chamber, make the first oxygen react with the gasified target atoms of the alloy target, and form an amorphous alloy layer with a bandgap ranging from 2eV to 5eV on the amorphous alloy layer Metal oxide layer, the amorphous metal oxide layer and the amorphous alloy layer jointly form the hard coating, the color of the hard coating can vary with the thickness of the amorphous metal oxide layer The variation varies over the wavelength range of visible light.

[0062] In the preparation method of the h...

Embodiment 1

[0072] Example 1——preparation of Tuhao golden hard coating

[0073] by component as Co 45 Fe 21 Ta 10 B 24 The alloy target is used as the raw material, and white Al is placed in the chamber of the magnetron sputtering equipment 2 o 3 Ceramic substrate; pre-evacuated to 10 -4Below Pa, feed argon and oxygen, adjust the partial pressure ratio of oxygen and argon to 0.03, and sputter to obtain a layer of bonding layer, whose composition is Co 25.2 Fe 8.3 Ta 6.4 B 19.5 o 40.6 , whose structure is a two-phase nanocomposite structure including an amorphous alloy and an amorphous metal oxide. Close the oxygen inlet valve and sputter in an argon atmosphere to obtain a single-phase CoFeTaB amorphous alloy layer with a thickness greater than 20 nm, and its composition is Co 55 Fe 24.5 Ta 0.1 B 20.4 ; Open the oxygen inlet valve again subsequently, and obtain a 120-nanometer thick single-phase amorphous metal oxide layer by sputtering under a mixed atmosphere with argon and...

Embodiment 2

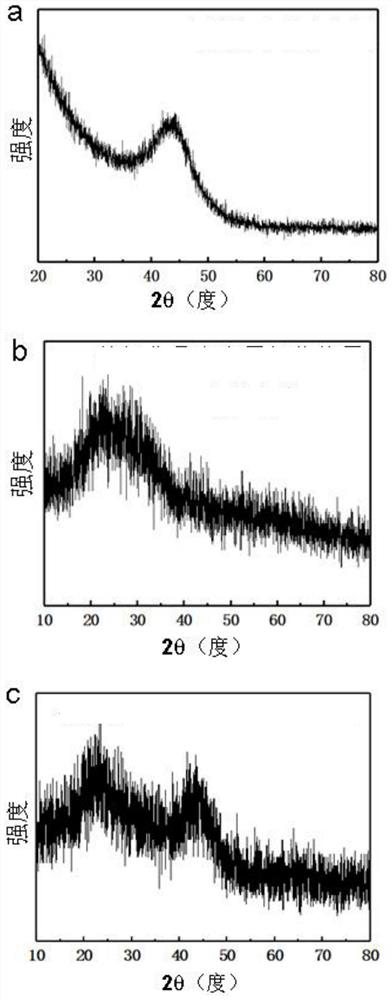

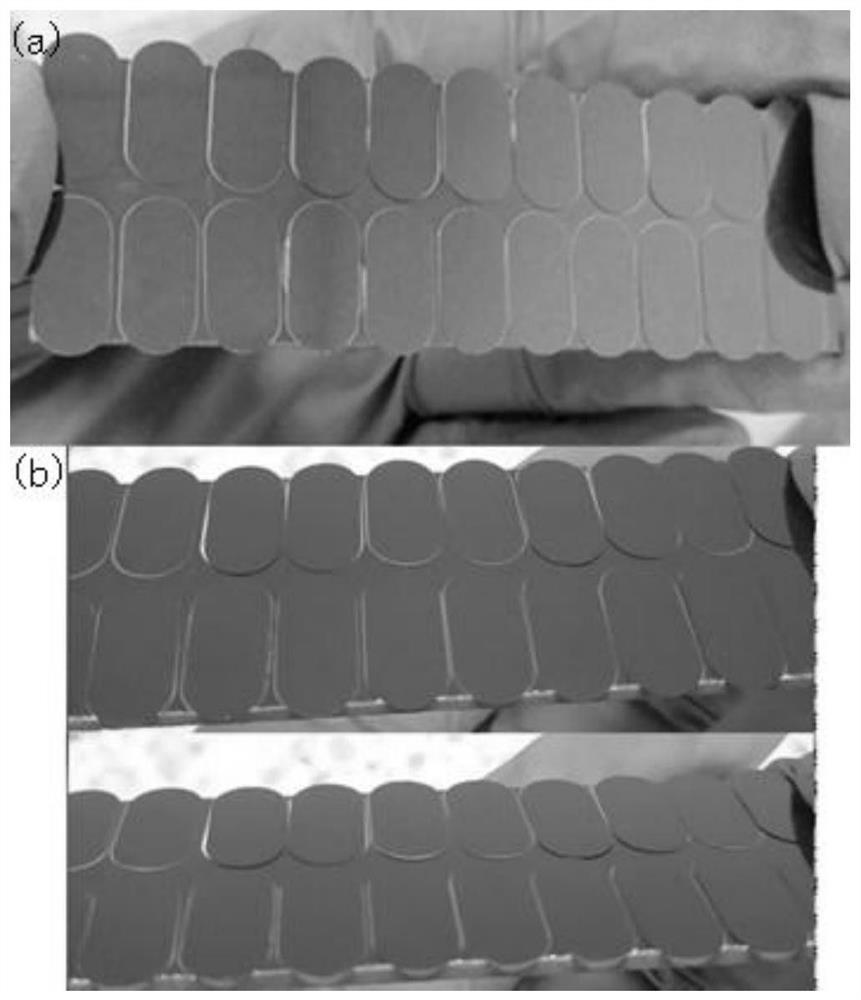

[0074] pass figure 1 a. figure 1 b and figure 1 c It can be seen that each layer in the hard coating obtained in this embodiment is amorphous. pass figure 2 It can be seen that the hard coating is a local gold color. Embodiment 2——preparation of blue hard coating

[0075] Embodiment 2——preparation of blue hard coating

[0076] The preparation method of Example 2 is substantially the same as that of Example 1, the only difference being that the substrate is a black ceramic substrate, and the thickness of the amorphous metal oxide layer is 180 nanometers.

[0077] The XRD and AFM results of the sample prepared in Example 2 are similar to the sample obtained in Example 1, so the results will not be repeated. From image 3 a It can be known that when the sample is observed from the front, the hard coating is blue, combined with image 3 b It can be seen that when the sample is viewed from the side, the hard coating has a purple color. Therefore, the hard coating obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com