Colorful antique plastic-wood composite material board and preparation method thereof

A technology of wood-plastic composite materials and boards, which is applied in the field of colorful antique wood-plastic composite boards and its preparation, and can solve problems such as poor decorability, difficult manufacturing process, unfavorable water and soil conservation, and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

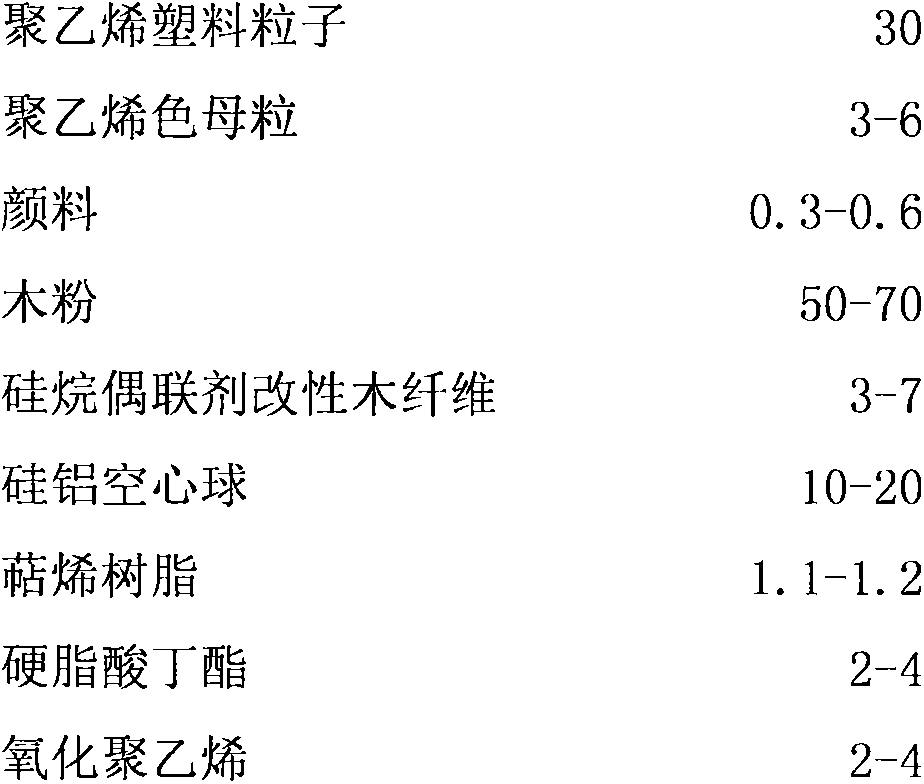

Method used

Image

Examples

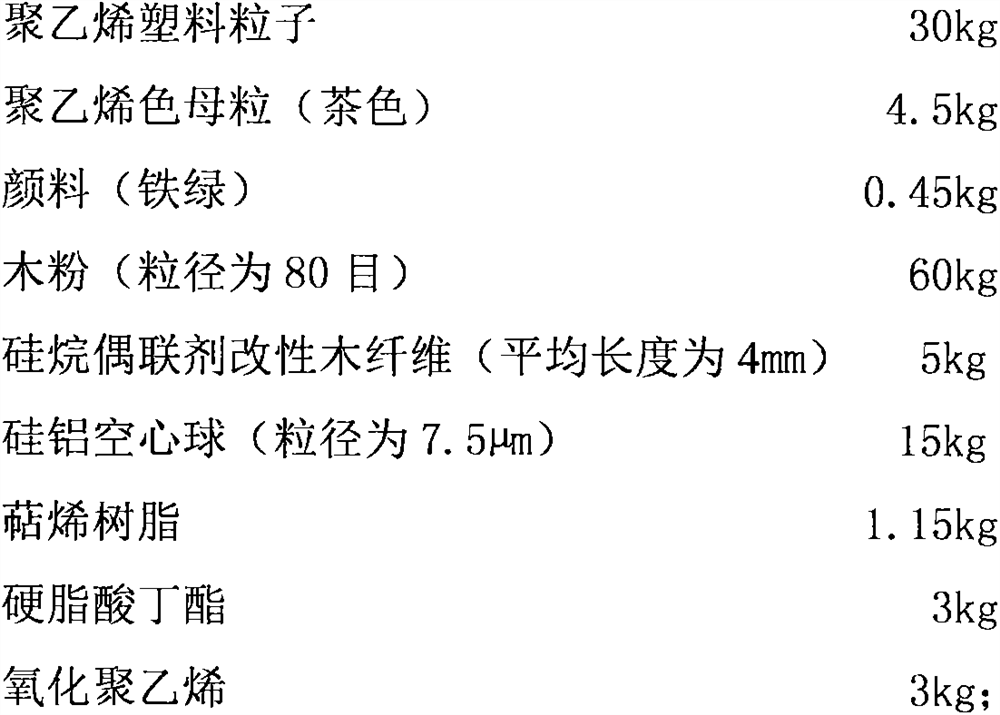

Embodiment 1

[0031]

[0032] (1) Weigh the formula amount and take wood fiber and silane coupling agent [vinyl tris (β-methoxyethoxy) silane] respectively according to the mass ratio of 100:6;

[0033] (2) Weigh the silane coupling agent, distilled water, hydrogen peroxide and ferrous chloride respectively by mass ratio 1: 100: 0.03: 0.05;

[0034] (3) Add silane coupling agent, distilled water and ferrous chloride into the pressure vessel, and stir to form silane coupling agent-ferrous chloride aqueous solution;

[0035] (4) adjust the pH value of the silane coupling agent-ferrous chloride aqueous solution to 5, then add hydrogen peroxide, and stir evenly;

[0036] (5) Add wood fibers to it, raise the temperature to 70°C, and perform ultrasonic treatment for 45min under a pressure of 0.5MPa;

[0037] (6) After the ultrasonic treatment is finished, the wood fibers are taken out, rinsed with distilled water to neutrality, and then vacuum-dried to obtain the silane coupling agent modifie...

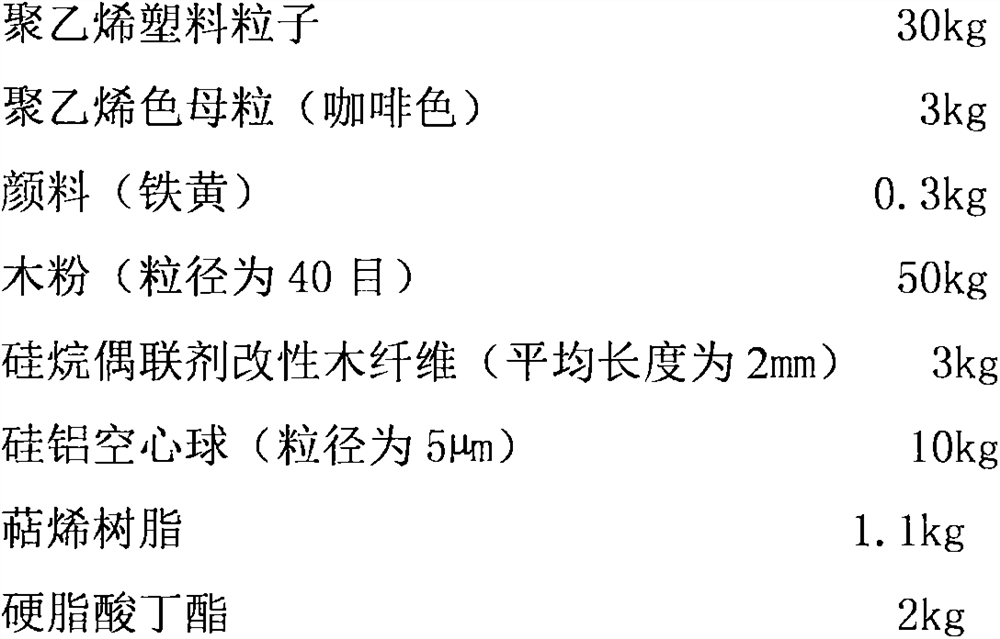

Embodiment 2

[0045]

[0046]

[0047] (1) Weigh the formula quantity and take the wood fiber and the silane coupling agent [vinyltriethoxysilane] respectively according to the mass ratio of 100:3;

[0048] (2) Weigh the silane coupling agent, distilled water, hydrogen peroxide and ferrous chloride respectively by mass ratio 1: 100: 0.03: 0.05;

[0049] (3) Add silane coupling agent, distilled water and ferrous chloride into the pressure vessel, and stir to form silane coupling agent-ferrous chloride aqueous solution;

[0050] (4) adjust the pH value of the silane coupling agent-ferrous chloride aqueous solution to 4, then add hydrogen peroxide, and stir evenly;

[0051] (5) Add wood fiber to it, heat up to 60°C, and ultrasonically treat for 30min under a pressure of 0.3MPa;

[0052] (6) After the ultrasonic treatment is finished, the wood fibers are taken out, rinsed with distilled water to neutrality, and then vacuum-dried to obtain the silane coupling agent modified wood fibers; ...

Embodiment 3

[0060]

[0061]

[0062] (1) Weighing the formula amount and taking wood fiber and silane coupling agent [3-(methacryloyloxy)propyltriethoxysilane] respectively according to the mass ratio of 100:9;

[0063] (2) Weigh the silane coupling agent, distilled water, hydrogen peroxide and ferrous chloride respectively by mass ratio 1: 100: 0.03: 0.05;

[0064] (3) Add silane coupling agent, distilled water and ferrous chloride into the pressure vessel, and stir to form silane coupling agent-ferrous chloride aqueous solution;

[0065] (4) adjust the pH value of the silane coupling agent-ferrous chloride aqueous solution to 6, then add hydrogen peroxide, and stir evenly;

[0066] (5) Add wood fiber to it, raise the temperature to 80°C, and perform ultrasonic treatment for 60min under a pressure of 0.7MPa;

[0067] (6) After the ultrasonic treatment is finished, the wood fibers are taken out, rinsed with distilled water to neutrality, and then vacuum-dried to obtain the silane c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com