Low-density gel particle modifying and flooding agent and preparation method thereof

A technology of gel particles and flooding agents, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of strength and aging performance decline, gel particle filler precipitation, and filler easy precipitation, etc., to achieve Maintain good strength, avoid easy precipitation, and maintain good aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

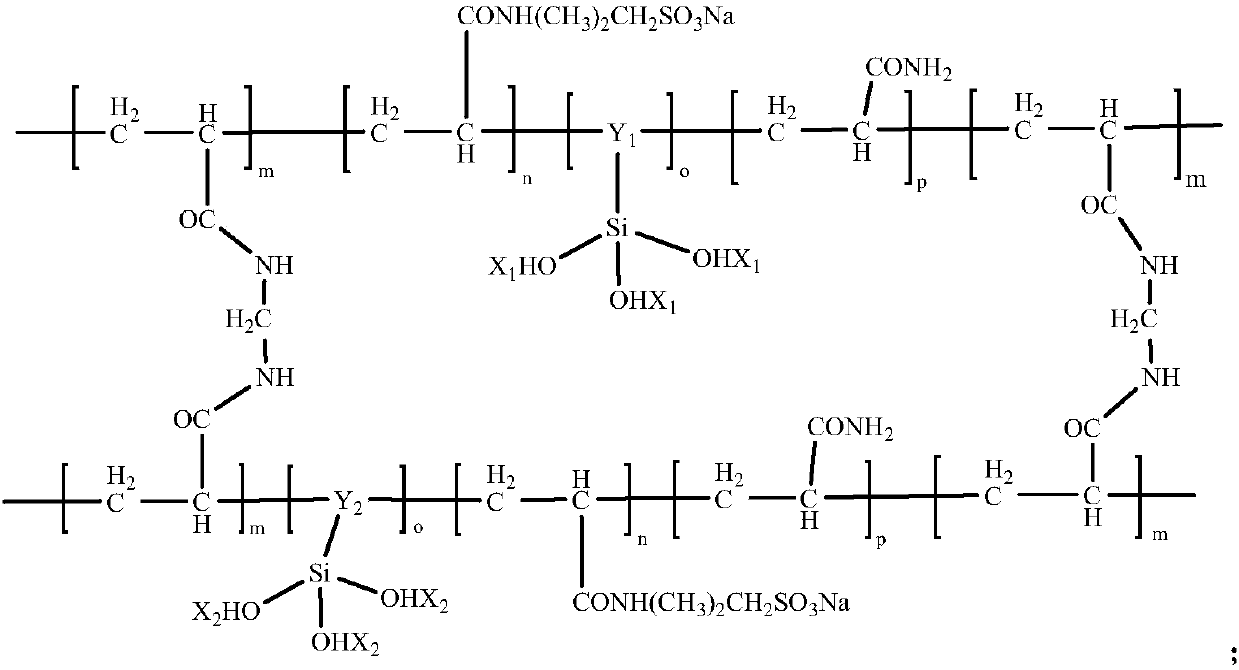

[0039] Embodiment 1 of the preparation method of the low-density gel particle control and displacement agent of the present invention, to prepare the gel particles involved in the low-density gel particle control and displacement agent embodiment 1, the following steps are adopted:

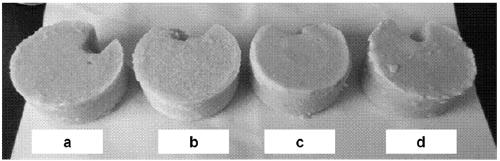

[0040] Dissolve acrylamide, sodium 2-acrylamido-2-methylpropanesulfonate, and N,N-methylenebisacrylamide in water, then add floating beads and γ-(2,3-epoxy Propoxy)propyltrimethoxysilane, stir well to obtain a suspension; at 25°C, add sodium bisulfite and ammonium persulfate, stir for 20min to form figure 1 The solid rubber block shown in (a) is placed under the condition of not lower than 20°C for 24 hours, then cut and granulated to obtain the low-density gel particle control and displacement agent. The cutting machine can be used for granulation. By adjusting the parameters, gel particles of different sizes can be formed. The particle size range is 1-10mm.

Embodiment 2

[0041] Embodiment 2 of the preparation method of the low-density gel particle regulating and displacing agent of the present invention, the gel particles involved in the low-density gel particle regulating and displacing agent embodiment 2, adopt the following steps:

[0042] Dissolve acrylamide, sodium 2-acrylamido-2-methylpropanesulfonate, and N,N-methylenebisacrylamide in water, then add hollow glass microspheres and methacryloxypropane under stirring base trimethoxysilane, stirred evenly to obtain a suspension; at 30°C, add sodium bisulfite and ammonium persulfate, and stir for 15 minutes to form figure 1 The solid gel block shown in (b) was placed at room temperature for 24 hours, then cut and granulated to obtain the low-density gel particle control and displacement agent.

[0043] Embodiment 3 of the preparation method of the low-density gel particle control and displacement agent of the present invention, to prepare the gel particles involved in the low-density gel par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com