Composition and flame retardant resin composition

A composition and resin technology, applied in the direction of fireproof coatings, etc., can solve the problems of surface smoothness and flame retardancy of processable molded products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

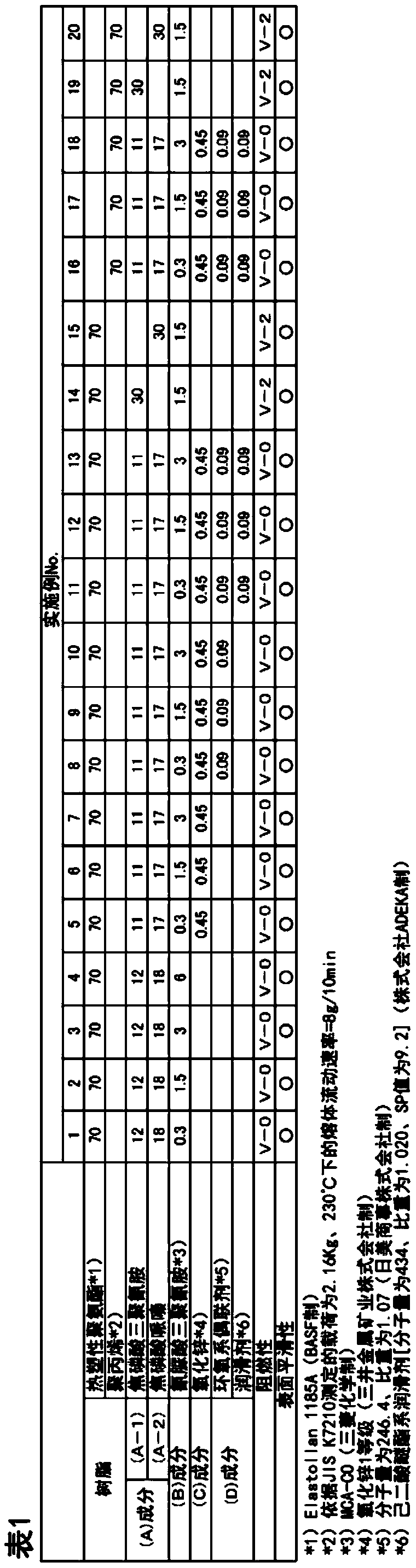

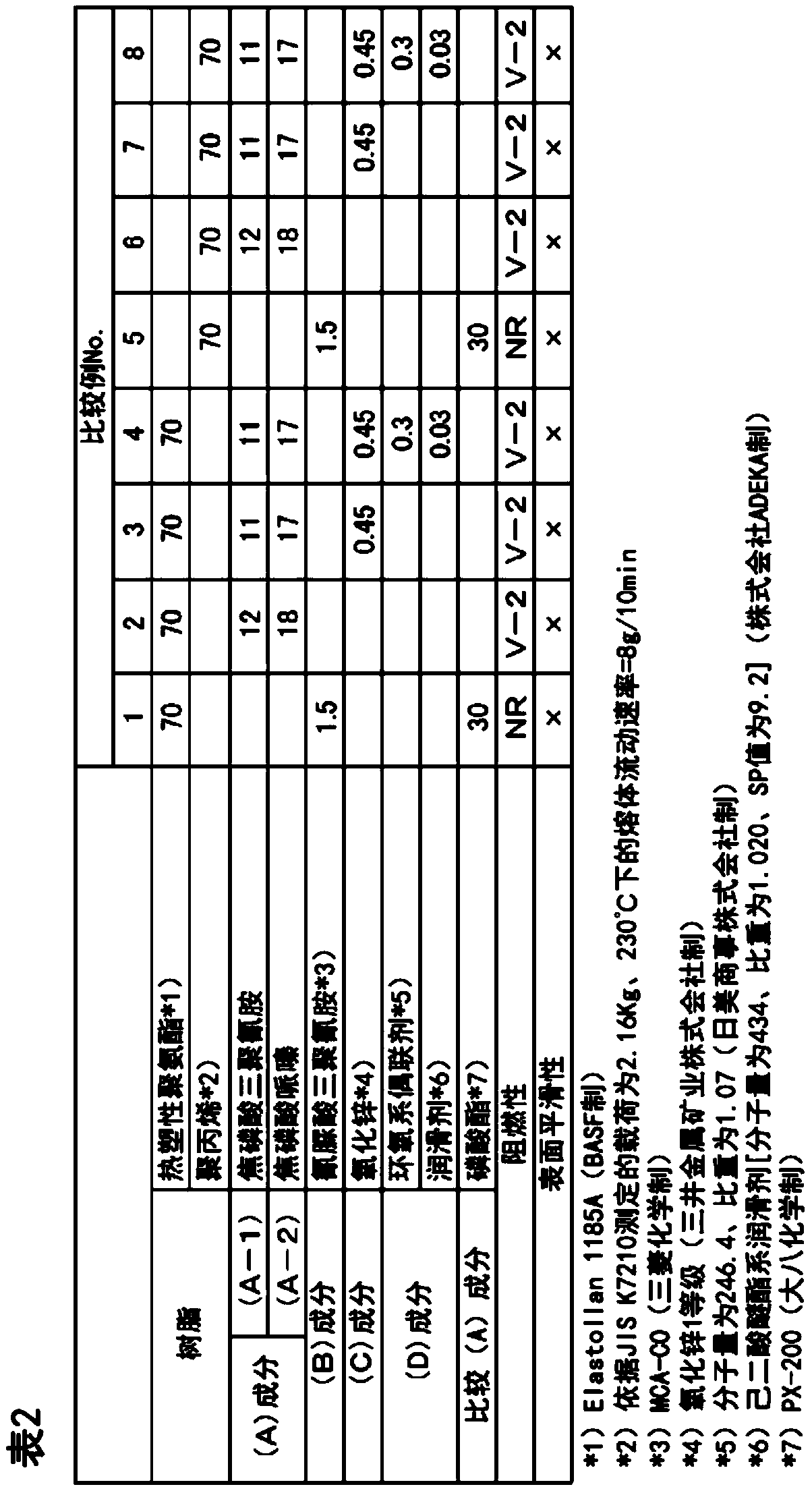

Embodiment 1~15 and comparative example 1~4

[0114] 0.1 part by mass of calcium stearate, 0.3 part by mass of glycerol monostearate, tetrakis[3-(3,5-di-tert-butyl-4-hydroxyl 0.1 parts by mass of phenyl) methyl propionate] methane, 0.1 parts by mass of 2,2'-methylenebis(4,6-di-tert-butylphenyl)-2-ethylhexyl phosphite, using Henscher The thermoplastic polyurethane resin composition was obtained by pre-mixing with a Er mixer. The compositions shown in Table 1 or 2 were blended in parts by mass described in the table with respect to the obtained thermoplastic polyurethane resin composition, and mixed with a Henschel mixer to obtain a flame-retardant resin composition.

Embodiment 16~20 and comparative example 5~8

[0116]0.1 parts by mass of calcium stearate (higher fatty acid metal salt), tetrakis[3- (3,5-di-tert-butyl-4-hydroxyphenyl) methyl propionate] methane (phenolic antioxidant) 0.1 parts by mass, tris (2,4-di-tert-butylphenyl) phosphite (phosphorus 0.1 parts by mass of an antioxidant) were premixed with a Henschel mixer to obtain a polypropylene resin composition. The compositions shown in Table 1 or Table 2 were blended in parts by mass described in the table with respect to the obtained polypropylene resin composition, and mixed with a Henschel mixer to obtain a flame-retardant resin composition.

[0117] Each of the resin compositions obtained above was prepared into pellets by the following method, and a test piece for flame retardancy evaluation was prepared from the pellets, and the evaluation piece was used for the following flame retardancy evaluation and surface smoothness evaluation. The results are shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com