Liquid-phase hydrofining method of poly DCPD petroleum resin based on modified nickel supported catalyst

A technology of supported catalysts and petroleum resins, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of affecting the service life of catalysts, reducing catalyst activity, increasing Energy consumption and other issues, to achieve the effect of eliminating mass transfer restrictions, increasing the ability of other impurities, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

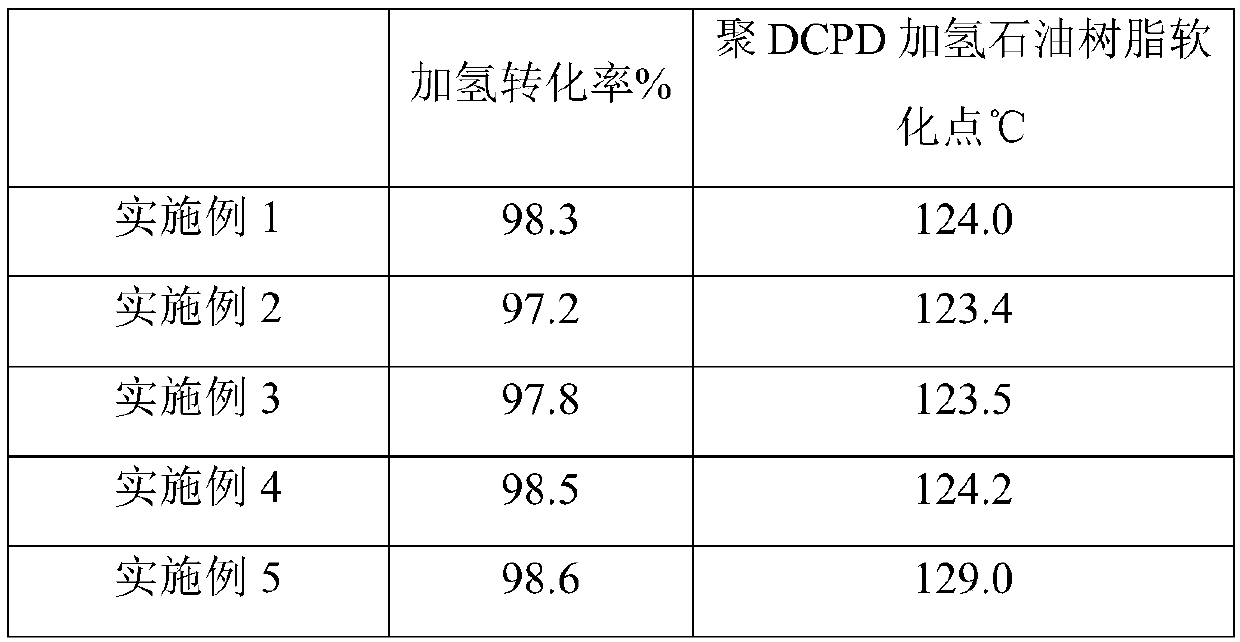

Examples

Embodiment 1

[0034] The preparation steps of the modified nickel-based supported catalyst in the present embodiment are as follows:

[0035] First equipped with alumina (γ-Al 2 o 3 ) sol, which is coated on the surface of 80g spherical activated carbon by 7 dipping methods, each dipping time is 10min, the dipping temperature is normal temperature, and the pressure is normal pressure. After filtering, it is first dried at 40°C for 3h, and then N 2 Calcined at 400°C for 4 hours in the atmosphere to obtain alumina (γ-Al 2 o 3 ) film-coated activated carbon support, alumina (γ-Al 2 o 3 ) and the weight ratio of activated carbon is 4:1;

[0036] Prepare a nickel nitrate aqueous solution with a concentration of 1.1mol / L and a nitrate solution of metallic iron with a concentration of 0.8mol / L, and then use an equal volume impregnation method to mix 100g of the above-prepared alumina (γ-Al 2 o 3 ) membrane-coated activated carbon carrier is immersed in a nickel nitrate aqueous solution and...

Embodiment 2

[0042] The preparation steps of the modified nickel-based supported catalyst in the present embodiment are as follows:

[0043] First equipped with alumina (γ-Al 2 o 3 ) sol, which is coated on the surface of 80g spherical activated carbon by 9 dipping methods, each dipping time is 15min, the dipping temperature is normal temperature, and the pressure is normal pressure. After filtering, it is first dried at 55°C for 5h, and then N 2 Calcined at 450°C for 5 hours in the atmosphere to obtain alumina (γ-Al 2 o 3 ) film-coated activated carbon support, alumina (γ-Al 2 o 3 ) and the weight ratio of activated carbon is 5:1;

[0044] Preparation concentration is the nickel nitrate aqueous solution of 1.2mol / L and the nitrate solution of metallic copper that the concentration is 0.8mol / L, adopts equal volume impregnation method then, the aluminum oxide (γ-Al of 100g 2 o 3 ) membrane-coated activated carbon support is immersed in a nickel nitrate aqueous solution and a metal c...

Embodiment 3

[0050] The preparation steps of the modified nickel-based supported catalyst in the present embodiment are as follows:

[0051] First equipped with alumina (γ-Al 2 o 3) sol, which is coated on the surface of 80g spherical activated carbon by 10 dipping methods, each dipping time is 13min, the dipping temperature is normal temperature, and the pressure is under normal pressure. After filtering, it is first dried at 35°C for 7h, and then in N 2 Calcined at 500°C for 6 hours in the atmosphere to obtain alumina (γ-Al 2 o 3 ) film-coated activated carbon support, alumina (γ-Al 2 o 3 ) and activated carbon in a weight ratio of 6:1.

[0052] Preparation concentration is the nickel nitrate aqueous solution of 1.1mol / L and the nitrate solution of the metallic cobalt that concentration is 0.8mol / L, adopts equal volume impregnation method then, the aluminum oxide (γ-Al 2 o 3 ) membrane-coated activated carbon support is immersed in a nickel nitrate aqueous solution and a metal co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com