Modified Y-type molecular sieve and preparation method and application thereof

A molecular sieve and modification technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as excess conversion, improve product selectivity and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

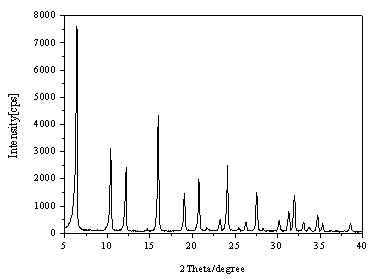

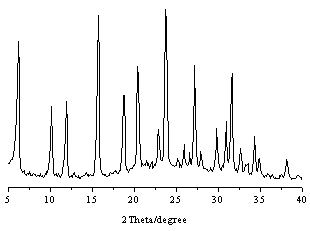

Image

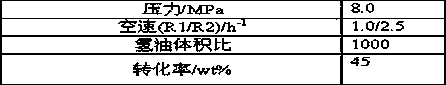

Examples

Embodiment 1

[0023] The NaY type molecular sieve raw material is subjected to the first ion exchange, and then the obtained NaNH 4 Y was placed in a high-temperature furnace at 750°C for 2.0 hours at a constant temperature, and then the second ion exchange was performed again, and then the obtained NH 4 Under the pressure of 0.25MPa, carry out constant temperature treatment in a hydrothermal furnace at 550°C for 1.5 hours, and finally treat the hydrothermally treated molecular sieve at 60°C with 1.5mol / L hydrochloric acid solution under stirring 1.5 hours, then washed to neutral, and dried at 90°C for 18 hours to obtain a modified Y-type molecular sieve with low crystallinity. The specific properties of molecular sieves are shown in Table 1.

[0024] The ammonium salt used in the first ion exchange process is ammonium chloride, the solid-liquid ratio of ion exchange is 1:8 (g / ml), the concentration of ammonium solution is 1.0mol / L, and the ion exchange temperature is 80°C. The constant t...

Embodiment 2

[0026] The NaY type molecular sieve is subjected to the first ion exchange, and then the obtained NaNH 4 Y was placed in a high-temperature furnace at 650°C for 3.0 hours at a constant temperature and then subjected to ion exchange for the second time, and then the obtained NH 4 Under the pressure of 0.15MPa, Y was subjected to constant temperature treatment in a hydrothermal furnace at 600°C for 2.0 hours, and finally the hydrothermally treated molecular sieve was treated at 90°C with 0.8mol / L nitric acid solution under stirring for 2.0 hours. hours, then washed to neutral, and dried at 100°C for 12 hours to obtain a modified Y-type molecular sieve with low crystallinity. The specific properties of molecular sieves are shown in Table 1.

[0027] The ammonium salt used in the first ion exchange process is ammonium sulfate, the solid-liquid ratio of ion exchange is 1:10 (g / ml), the concentration of ammonium solution is 1.6mol / L, and the ion exchange temperature is 90°C. The c...

Embodiment 3

[0029] The NaY type molecular sieve is subjected to the first ion exchange, and then the obtained NaNH 4 Y was placed in a high-temperature furnace at 800°C for 2.0 hours at a constant temperature, and then the second ion exchange was performed again, and then the obtained NH 4 Under the pressure of 0.08MPa, Y was subjected to a constant temperature treatment in a hydrothermal furnace at 450°C for 3.0 hours, and finally the hydrothermally treated molecular sieve was treated at 60°C with 1.6mol / L acid solution under stirring for 1.0 hours, then washed to neutral, and dried at 110°C for 16 hours to obtain a modified Y-type molecular sieve with low crystallinity. The specific properties of molecular sieves are shown in Table 1.

[0030] The ammonium salt used in the first ion exchange process is ammonium nitrate, the solid-liquid ratio of ion exchange is 1:12 (g / ml), the concentration of ammonium solution is 2.0mol / L, and the ion exchange temperature is 90°C. The constant tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com