The preparation method of silicon germanium stf zeolite molecular sieve

A zeolite molecular sieve, silicon germanium technology, which is applied in the direction of molecular sieve catalyst, crystalline aluminosilicate zeolite, molecular sieve and alkali exchange compound, etc., can solve the problems of increasing the preparation cost of STF molecular sieve, complex structure of organic template agent, limited availability, etc. It is easy to promote, enhance the structural orientation, and the effect of strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

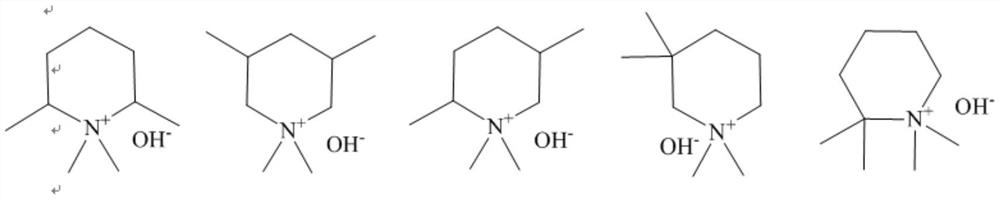

[0024] Dissolve 3.5g of germanium oxide in 76.8g of 1,1,2,6-TMPOH aqueous solution (20wt%), add 34.7g of tetraethyl orthosilicate (TEOS), after the hydrolysis is complete, stir the container open overnight to volatilize ethanol and some water until the reaction mixture reaches the final molar composition.

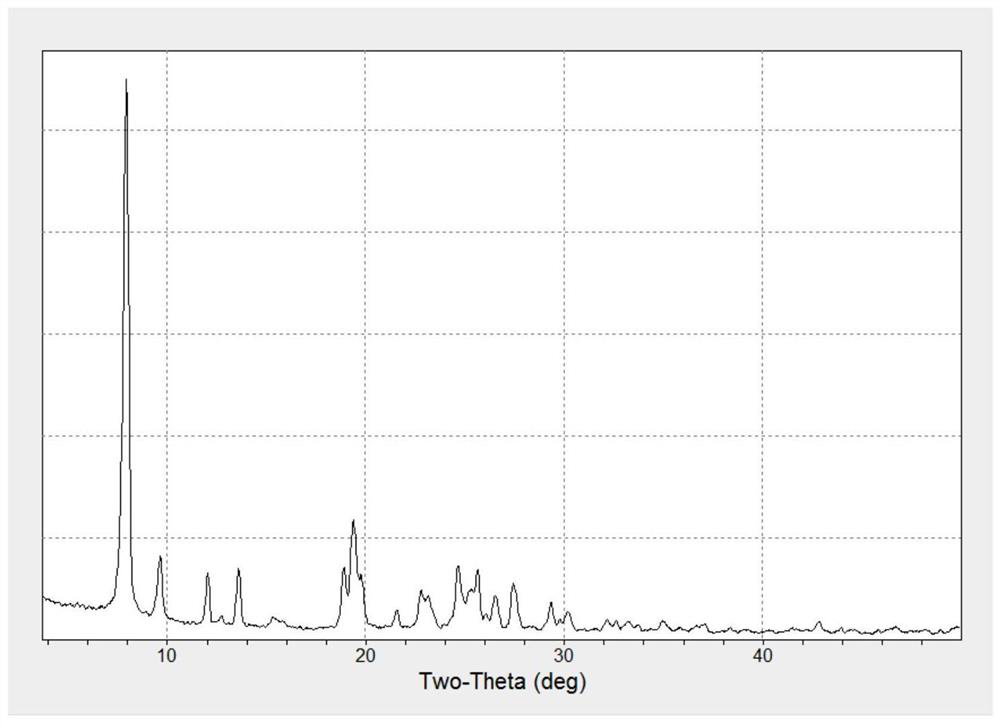

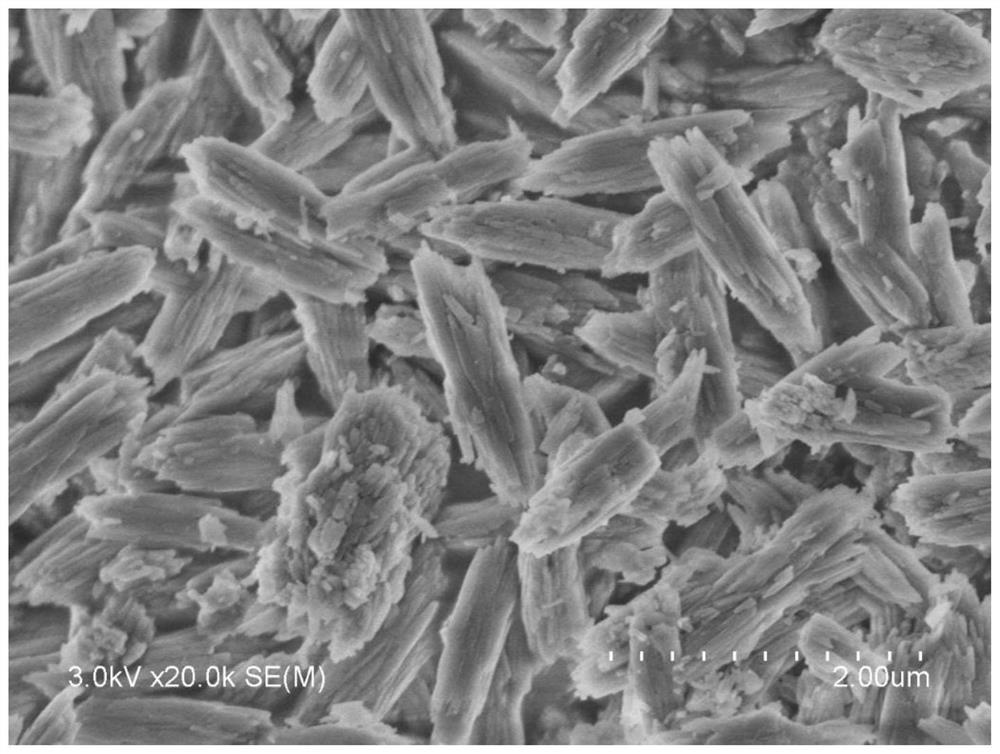

[0025] The above mixture was put into a crystallization kettle with a polytetrafluoroethylene liner, and placed in an oven at 150°C for crystallization for 168 hours. The solid obtained after the reaction is filtered, washed, dried and calcined is STF molecular sieve. The XRD pattern of the sample is as figure 1 As shown, the scanning electron microscope photo is shown as figure 2 shown.

Embodiment 2

[0027] Dissolve 10g of germanium oxide in 105.2g of 1,1,2,6-TMPOH aqueous solution (20wt%), add 41.6g of tetraethyl orthosilicate (TEOS), after the hydrolysis is complete, stir the container open overnight to volatilize ethanol and portion of water until the reaction mixture reaches the final molar composition.

[0028] The above mixture was put into a crystallization kettle with a polytetrafluoroethylene liner, and placed in an oven at 175°C for crystallization for 96 hours. The solid obtained after the reaction is filtered, washed, dried and calcined is STF molecular sieve.

Embodiment 3

[0030] Dissolve 1.9g of germanium oxide in 45.5g of 1,1,3,5-TMPOH aqueous solution (20wt%), add 37.9g of tetraethyl orthosilicate (TEOS), after the hydrolysis is complete, stir the container open overnight to volatilize ethanol and some water until the reaction mixture reaches the final molar composition.

[0031] The above mixture was put into a crystallization kettle with a polytetrafluoroethylene liner, and placed in an oven at 160°C for crystallization for 180 hours. The solid obtained after the reaction is filtered, washed, dried and calcined is STF molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com