Regeneration and recovery device and method of methanol alkali metal salt catalyst in dimethyl carbonate synthesis process by ester exchange method

A technology of alkali metal methanol salt and dimethyl carbonate, applied in the field of chemical industry, can solve the problems of inability to reuse, consume and the like, and achieve the effects of easy operation, reduced production cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

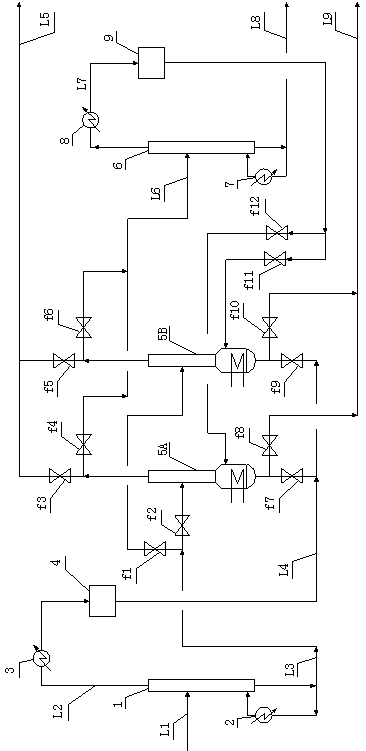

[0030] A kind of recovery method of methanol alkali metal salt catalyst in the synthesizing dimethyl carbonate process of transesterification method, comprises the following steps:

[0031] (1) Evaporation: First, the liquid L1 (including methanol, propylene carbonate, 1,2-propylene glycol, catalyst) after transesterification to dimethyl carbonate reaction is introduced into the evaporator 1 for distillation, the condition is: 0.1MPa, the tower kettle temperature is 70 o C, the temperature at the top of the tower is 64 o C, most of the methanol L2 is separated, and enters the storage tank 4 after being condensed by the condenser 3;

[0032] (2) Reactive distillation: valve f1, valve f7, and valve f8 are closed, valve f2 is opened, and the remaining liquid L3 in evaporator 1 (including propylene carbonate, 1,2-propylene glycol, methanol, and catalyst) enters the first distillation column 5A , then the f3 valve is opened, the f2 valve, f7 valve, and f8 valve are closed, at 0.0...

Embodiment 2

[0035] Process is identical with embodiment 1, and the operation condition of distillation tower 1 is 0.05MPa, and tower still temperature is 50 o C, the temperature at the top of the tower is 47 o C; The distillation conditions of the first distillation tower 5A and the second distillation tower 5B are: 0.1MPa, 250 o C; the reaction conditions are: the ratio of methanol:distilled material is 20:1 (wt), 0.05MPa, 100 o C, the reaction time is 35 hours; the operating conditions of the alcohol-water separation tower 6 are: 0.02MPa, the temperature of the tower kettle is 40 o C, tower top temperature 38 o c.

Embodiment 3

[0037] Process is identical with embodiment 1, and the operation condition of distillation tower 1 is 0.01MPa, and tower still temperature is 40 o C, the temperature at the top of the tower is 35 o C; The distillation conditions of the first distillation tower 5A and the second distillation tower 5B are: 0.05MPa, the temperature of the tower bottom is 50 o C, tower top temperature 45 o C; the reaction conditions are: the ratio of methanol:distilled material is 0.6:1 (wt), 0.02MPa, 80 o C, the reaction time is 50 hours; the operating conditions of the alcohol-water separation tower 6 are: 0.05MPa, the temperature of the tower kettle is 50 o C, tower top temperature 47 o c.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com