A kind of europium-doped microspherical fluorescent powder and its preparation method

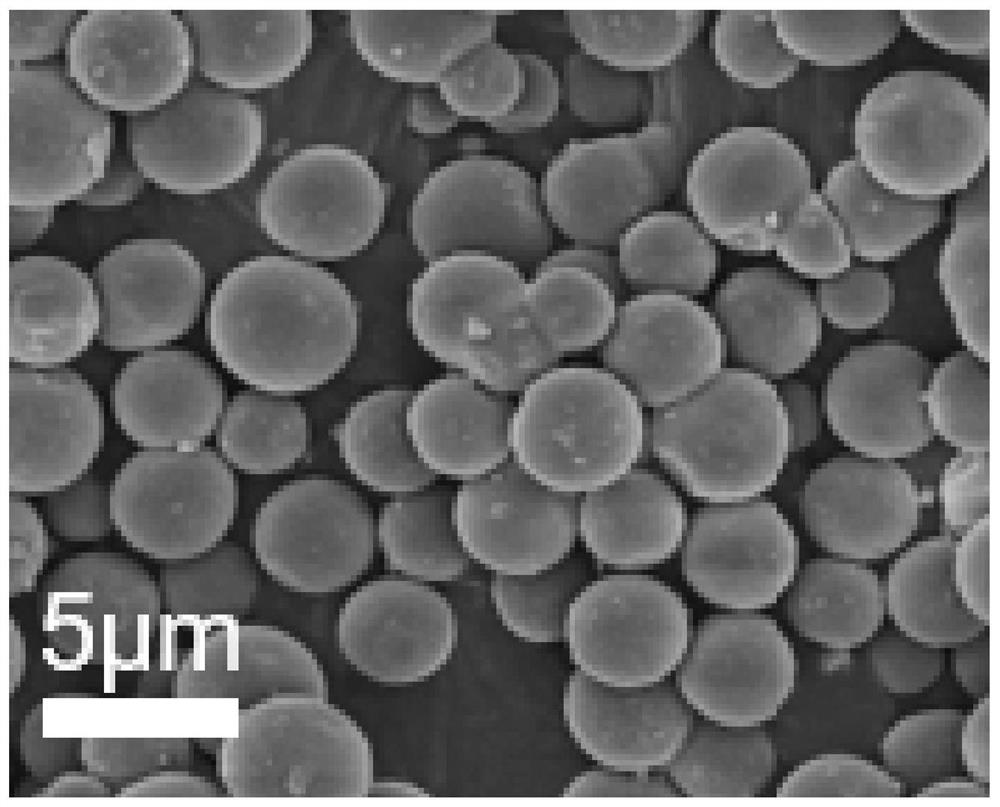

A phosphor and spherical technology is applied in the field of europium doped micro-spherical phosphor and its preparation, which can solve the problems of uneven size, irregular shape, high energy consumption for sintering, and achieve regular morphology, low scattering and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) Weigh 2.0g AlCl 3 ﹒ 6H 2 O, 0.54g CaCl 2 , 0.00178g EuCl 3 ﹒ 6H 2 0 and 0.3mL tetraethyl orthosilicate (TEOS) in a 50ml beaker, add 1mL surfactant formamide (FA), 4mL deionized water and 4mL absolute ethanol to obtain a mixed solution;

[0017] (2) Keep the mixed solution at 25°C for continuous magnetic stirring (1000 revolutions per minute), and wait for the AlCl 3 ﹒ 6H 2 O, CaCl 2 , EuCl 3 ﹒ 6H 2 After O was completely hydrolyzed, 13 mL of propylene oxide (PO) was quickly injected into the mixed solution to drive the gelation reaction;

[0018] (3) Keep stirring rapidly after adding PO, and stop stirring when PO is evenly dispersed. Obtain milky white gel after standing for 5 minutes;

[0019] (4) Put the prepared gel in a Petri dish and dry it in an oven at 80°C for 12 hours to obtain an amorphous precursor;

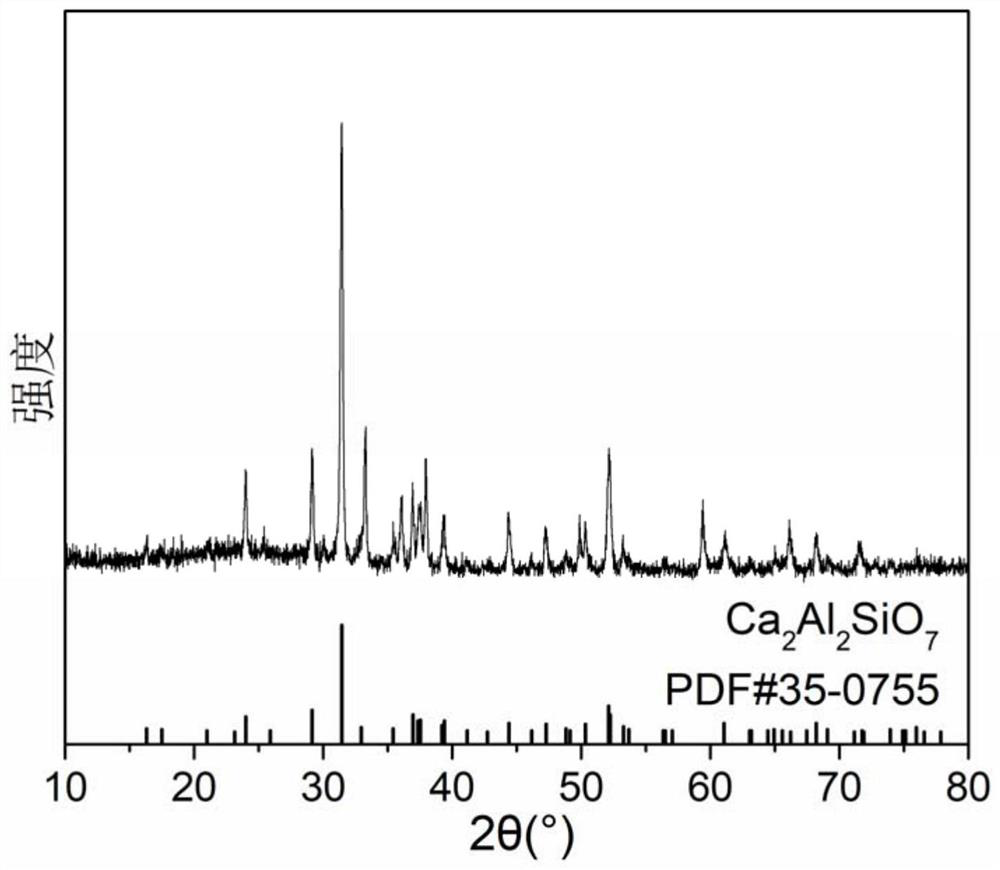

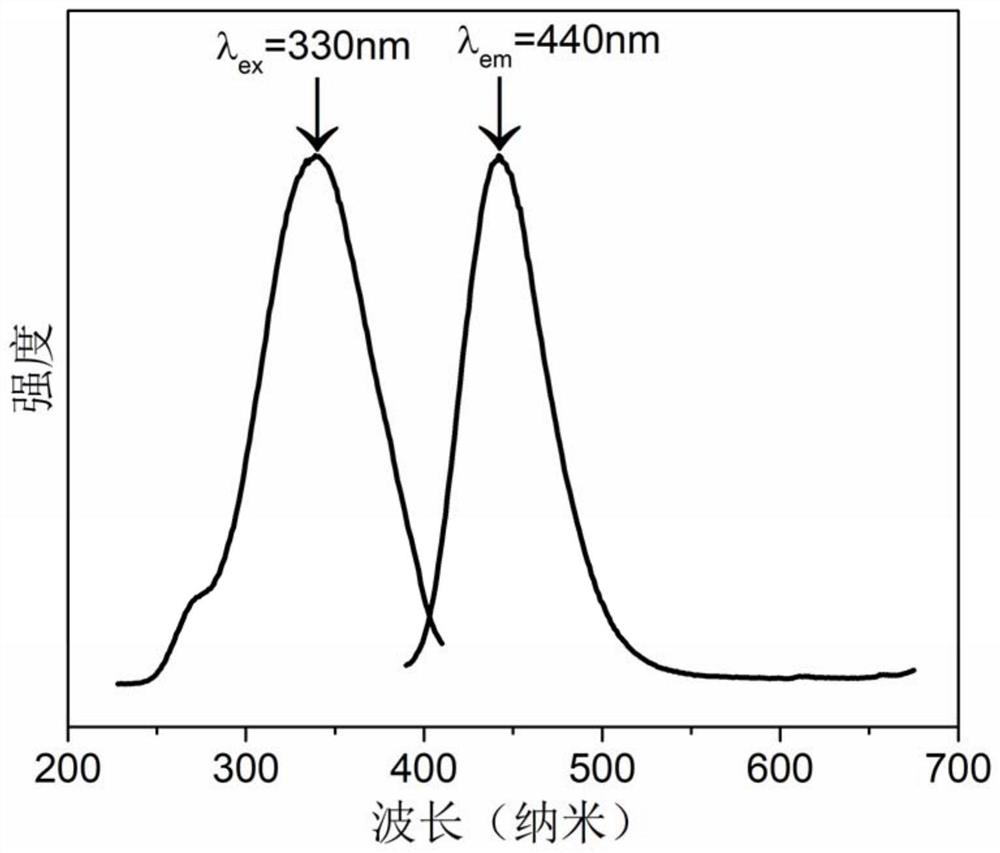

[0020] (5) Spread the prepared precursor in an alumina burning boat, then place it in a tube furnace and heat it up to 1200°C, and heat it i...

Embodiment 2

[0023] (1) Weigh 2.0g AlCl 3 ﹒ 6H 2 O, 0.54g CaCl 2 , 0.00896g EuCl 3 ﹒ 6H 2 0 and 0.3mL tetraethyl orthosilicate (TEOS) in a 50ml beaker, add 1mL surfactant formamide (FA), 4mL deionized water and 4mL absolute ethanol to obtain a mixed solution;

[0024] (2) Keep the mixed solution at 30°C for continuous magnetic stirring (1000 revolutions per minute), and wait for the AlCl 3 ﹒ 6H 2 O, CaCl 2 , EuCl 3 ﹒ 6H 2 After O was completely hydrolyzed, 12 mL of propylene oxide (PO) was quickly injected into the solution to drive the gelation reaction;

[0025] (3) Keep stirring rapidly after adding PO, and stop stirring when PO is evenly dispersed. Obtain milky white gel after standing for 5 minutes;

[0026] (4) Put the prepared gel in a Petri dish and dry it in an oven at 70°C for 12 hours to obtain an amorphous precursor;

[0027] (5) Spread the prepared precursor in an alumina burning boat, then place it in a tube furnace and heat it up to 1150°C, and heat it in an a...

Embodiment 3

[0030] (1) Weigh 2.0g AlCl 3 ﹒ 6H 2 O, 0.54g CaCl 2, 0.01800g EuCl 3 ﹒ 6H 2 0 and 0.3mL tetraethyl orthosilicate (TEOS) in a 50ml beaker, add 1mL surfactant formamide (FA), 4mL deionized water and 4mL absolute ethanol to obtain a mixed solution;

[0031] (2) Keep the mixed solution at 35°C for continuous magnetic stirring (1000 revolutions per minute), and wait for the AlCl 3 ﹒ 6H 2 O, CaCl 2 , EuCl 3 ﹒ 6H 2 After complete hydrolysis of O, 13 mL of propylene oxide (PO) was quickly injected into the solution to drive the gelation reaction;

[0032] (3) Continue to stir after adding PO, and stop stirring when PO is evenly dispersed. Obtain milky white gel after standing for 5 minutes;

[0033] (4) Put the prepared gel in a Petri dish and dry it in an oven at 80°C for 12 hours to obtain an amorphous precursor;

[0034] (5) Spread the prepared precursor in an alumina burning boat, then place it in a tube furnace and heat it up to 1200°C, and heat it in an ammonia re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com