High-specific-surface-area carbon material based on waste tobacco stems, and preparation method and application thereof

A high specific surface area, carbon material technology, applied in chemical instruments and methods, carbon compounds, other chemical processes, etc., can solve the problems of less research, achieve the effects of rich sources, improved wettability, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for preparing a high specific surface area carbon material based on waste tobacco rods, comprising the steps of:

[0042] (1) Raw material pretreatment

[0043]Wash the soil on the tobacco stalks with clean water, remove the roots of the tobacco stalks and the remaining tobacco leaves and dry them naturally, then cut off the outer skin and cut them into pieces, send them into the crusher, and crush them into 50-200 mesh tobacco stalk powder, and put them in the oven Insulate at 70°C for 24 hours and dry for later use.

[0044] (2) Preparation of carbonized material

[0045] Pre-pyrolyze the tobacco rod powder obtained in step (1) in a tube furnace, raise the temperature to 550°C at a rate of 5°C / min in a nitrogen atmosphere (flow rate: 3mL / min), keep it warm for 2 hours, and drop to Take it out after room temperature to obtain carbonized material.

[0046] (3) Preparation of activation material

[0047] Grind and mix the carbonized material obtained in step...

Embodiment 2

[0051] Example 2: Only change the ratio of carbonized material to KOH in step (3) of Example 1 to 1:4, and refer to Example 1 for the remaining parameters and steps.

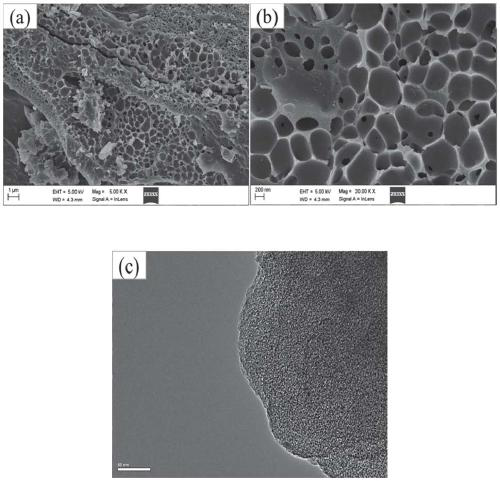

[0052] Figure 5 It is the topography figure of the carbon material obtained in Example 2, wherein (a) is an SEM figure, and (b) is a transmission electron microscope figure; Figure 6 It is the carbon material isothermal nitrogen adsorption-desorption curve obtained in Example 2; Figure 7 It is the pore size distribution diagram of the carbon material obtained in Example 2.

Embodiment 3

[0053] Embodiment 3: Only change the activation temperature of step (3) of the embodiment to 700° C., and refer to embodiment 1 for the remaining parameters and steps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com