Photoresist resin monomer synthesized by aldopentose and its synthesis method

A technology of resin monomer and synthesis method, which is applied in the field of photoresist resin monomer and its synthesis, can solve the problem of low resolution of photolithographic patterns, and achieve the goals of improving resolution, increasing corrosion resistance, and improving adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

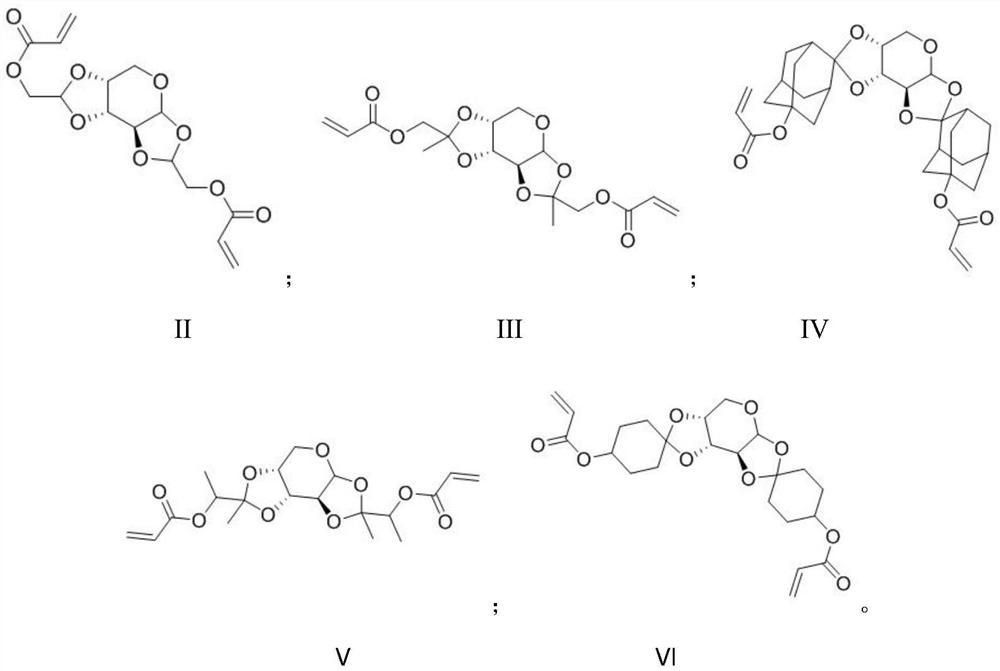

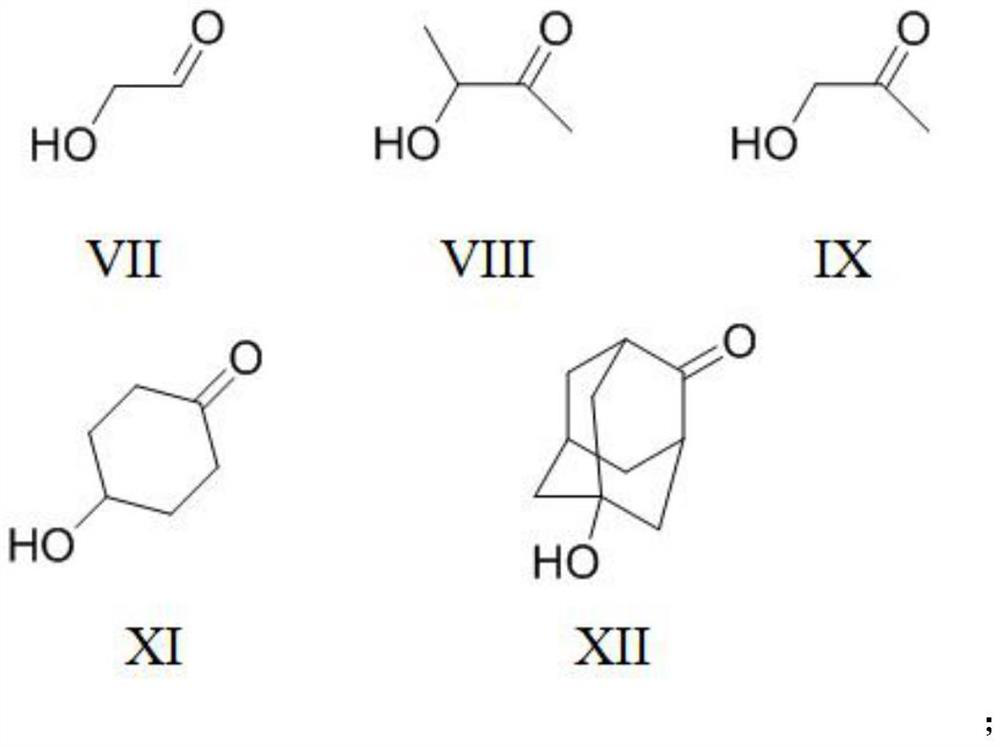

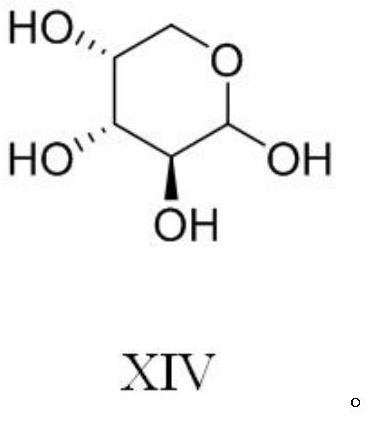

[0028] This embodiment provides a kind of photoresist resin monomer synthesized by aldopentose, the reaction scheme of the synthetic method of this photoresist resin monomer is as follows:

[0029]

[0030] It specifically includes the following steps:

[0031] S1. After dissolving glycolaldehyde (formula A1, 20g, 333mmol) in dichloromethane (200mL), add triethylamine (68g, 672mmol), and place in an ice-water bath to cool to 0°C; then, Slowly add acryloyl chloride (30.2g, 334mmol) dropwise. After the dropwise addition, continue to stir for 1 hour at 0°C. Then, slowly raise the temperature to normal temperature and continue to stir for 3 hours to react. After the reaction, add the reaction solution to the ice. Quenched in water (100mL), neutralized with saturated sodium bicarbonate solution, extracted three times with dichloromethane (80mL*3), the obtained organic phase was washed with saturated brine, dried over anhydrous sodium sulfate, and then vacuum-spun Dry to obtain ...

Embodiment 2

[0034] This embodiment provides a kind of photoresist resin monomer synthesized by aldopentose, the reaction scheme of the synthetic method of this photoresist resin monomer is as follows:

[0035]

[0036] It specifically includes the following steps:

[0037] S1, after dissolving hydroxyacetone (formula B1, 20g, 270mmol) in dichloromethane (200mL), add triethylamine (55g, 544mmol), and place in an ice-water bath to cool to 0°C; then, slowly Add acryloyl chloride (30.2g, 334mmol) dropwise, and continue stirring at 0°C for 1 hour after the dropwise addition. Then, slowly raise the temperature to normal temperature, and continue stirring for 3 hours for reaction. After the reaction, add the reaction solution to ice water ( 100mL), and neutralized with saturated sodium bicarbonate solution, extracted three times with dichloromethane (80mL*3), the obtained organic phase was washed with saturated brine, dried over anhydrous sodium sulfate, and then vacuum spin-dried to obtain ...

Embodiment 3

[0040] This embodiment provides a kind of photoresist resin monomer synthesized by aldopentose, the reaction scheme of the synthetic method of this photoresist resin monomer is as follows:

[0041]

[0042] It specifically includes the following steps:

[0043] S1. After dissolving p-hydroxycyclohexanone (formula C1, 20g, 175mmol) in dichloromethane (200mL), add triethylamine (36g, 356mmol), and place in an ice-water bath to cool to 0°C; then , slowly add acryloyl chloride (15.9g, 176mmol) dropwise, continue to stir at 0 degrees Celsius for 1 hour after the dropwise addition, then slowly raise the temperature to normal temperature, continue to stir for 3 hours to react, after the reaction is over, add the reaction solution to Quenched in ice water (100mL), neutralized with saturated sodium bicarbonate solution, extracted three times with dichloromethane (80mL*3), the obtained organic phase was washed with saturated brine, dried over anhydrous sodium sulfate, and vacuum Spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com