Nanofiber aerogel-based solar water evaporator and preparation method thereof

A nanofiber, water evaporator technology, applied in chemical instruments and methods, chemical characteristics of fibers, general water supply saving, etc., can solve the problems of complex preparation, poor thermal conductivity of solar water evaporators, etc. Light-to-heat conversion efficiency, light-weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The present embodiment provides a nanofiber aerogel-based solar water evaporator and a preparation method, and the specific steps are as follows:

[0046] Step 1): Preparation of polyamic acid nanofibers:

[0047]Dissolve 4.0048g of 4,4'-diaminodiphenyl ether in 50g of N,N-dimethylacetamide solvent, add 4.4278g of pyromellitic dianhydride, and react in an ice-water bath for 5h to obtain a polyamic acid spinning solution ; Add the prepared polyamic acid spinning solution into a syringe, carry out electrospinning, and electrospinning parameters: the voltage is 15kV, the bolus injection speed is 0.06mm / min, and the receiving speed is 100r / min to obtain polyamic acid nanofibers;

[0048] Step 2): Preparation of water-soluble polyamic acid:

[0049] Using N,N-dimethylacetamide as solvent, through condensation polymerization of 4,4'-diaminodiphenyl ether and terephthalic anhydride in an equimolar ratio in an ice-water bath to obtain a solid content of 15% of polyamic acid. ...

Embodiment 2

[0055] The difference between this example and Example 1 is that the amount of pyrrole monomer added dropwise in step 4) is 300 mg, and the rest are the same as in Example 1. That is, 300 mg of pyrrole monomer solution was added dropwise to the surface of the polyimide nanofiber aerogel with a surface size of 2cm×2cm and a height of 1cm to obtain a nanofiber aerogel-based solar water evaporator, denoted as PI-PPy-2 .

Embodiment 3

[0057] The difference between this example and Example 1 is that the amount of pyrrole monomer added dropwise in step 4) is 500 mg, and the rest are the same as in Example 1. That is, 500 mg of pyrrole monomer solution was added dropwise to the surface of the polyimide nanofiber aerogel with a surface size of 2cm×2cm and a height of 1cm to obtain a nanofiber aerogel-based solar water evaporator, denoted as PI-PPy-3 .

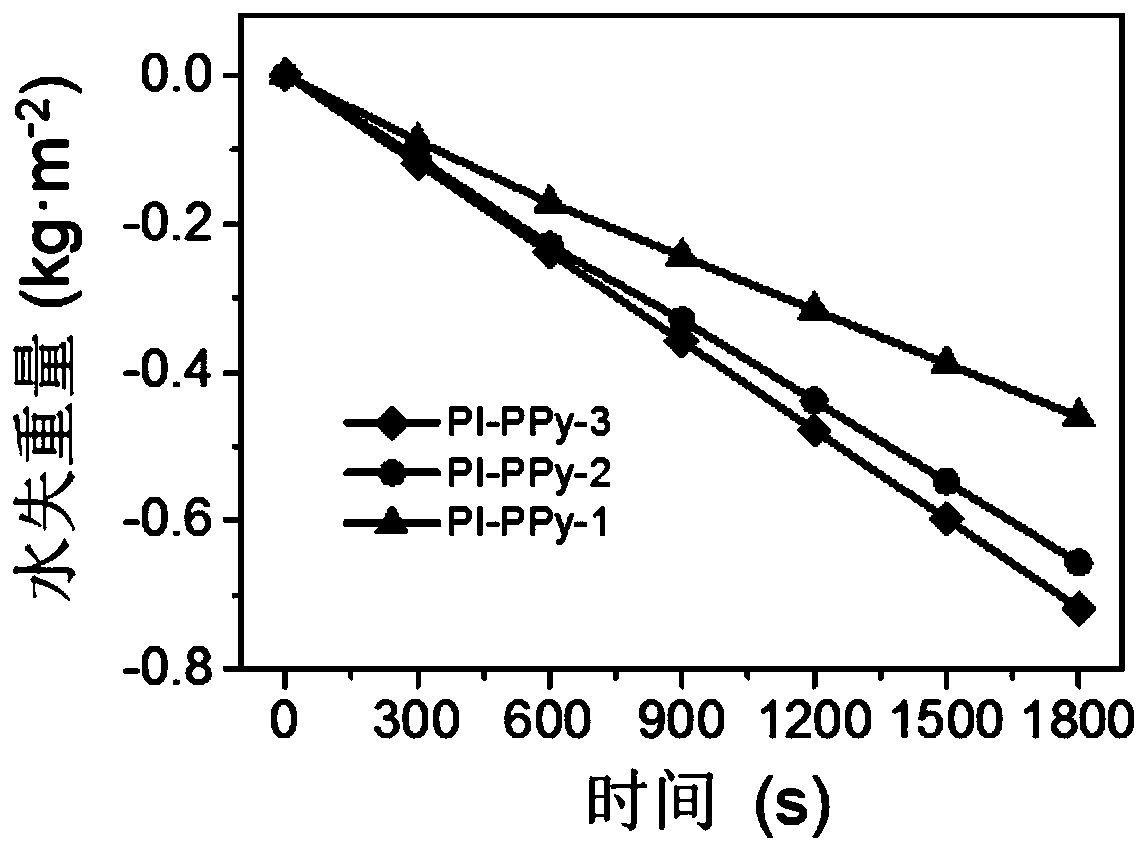

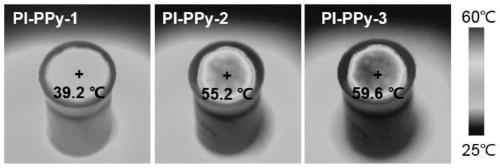

[0058] figure 1 The water loss weight-time relationship curve of the nanofiber aerogel-based solar water evaporator prepared for Examples 1-3, wherein the water weight loss of PI-PPy-3 is the largest, followed by PI-PPy-2, and the least is PI -PPy-1, indicating that PI-PPy-3 has the best evaporation effect. Because the more water loses weight, the more water vapor is produced during the evaporation process, and the higher the evaporation efficiency is. (Place the sample in a beaker with water, place it under a solar simulator, use an electronic balance to ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com