A kind of broadband near-infrared luminescent material and its preparation method and application

A luminescent material, near-infrared technology, applied in luminescent materials, chemical instruments and methods, semiconductor devices, etc., can solve the problems of low luminous efficiency, poor chemical stability, fluorescence heat quenching, etc., achieve high luminous efficiency, low cost, The effect of low thermal quenching of fluorescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Preparation of Gd 3 sc 1.47 Al 0.5 Cr 0.03 Ga 3 o 12 :

[0043] Press Gd3 sc 1.47 Al 0.5 Cr 0.03 Ga 3 o 12 The molar mass ratio of each element in the medium, accurately weigh the high-purity Gd 2 o 3 , Sc 2 o 3 , Cr 2 o 3 , Ga 2 o 3 , Al 2 o 3 , and 3 wt% H 3 BO 3 As a flux, the mixed powder is obtained after fully grinding; the obtained mixed powder is sintered at 1380°C in the air for 6 hours, and after cooling down, it is properly ground, and then sintered again at 1380°C in the air for 6 hours; after cooling, the obtained sintered product is Grinding, washing, and grading treatment can obtain the desired near-infrared luminescent material.

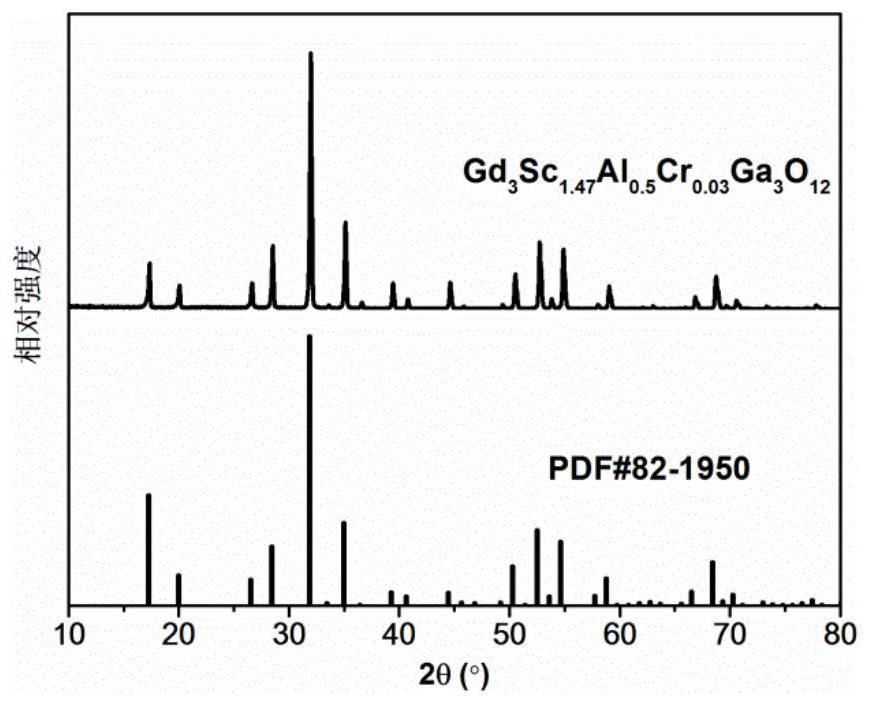

[0044] Such as figure 1 Shown is the XRD collection of samples of the sample prepared by the present embodiment, by the attached figure 1 It can be seen that the luminescent material is a single garnet crystal phase.

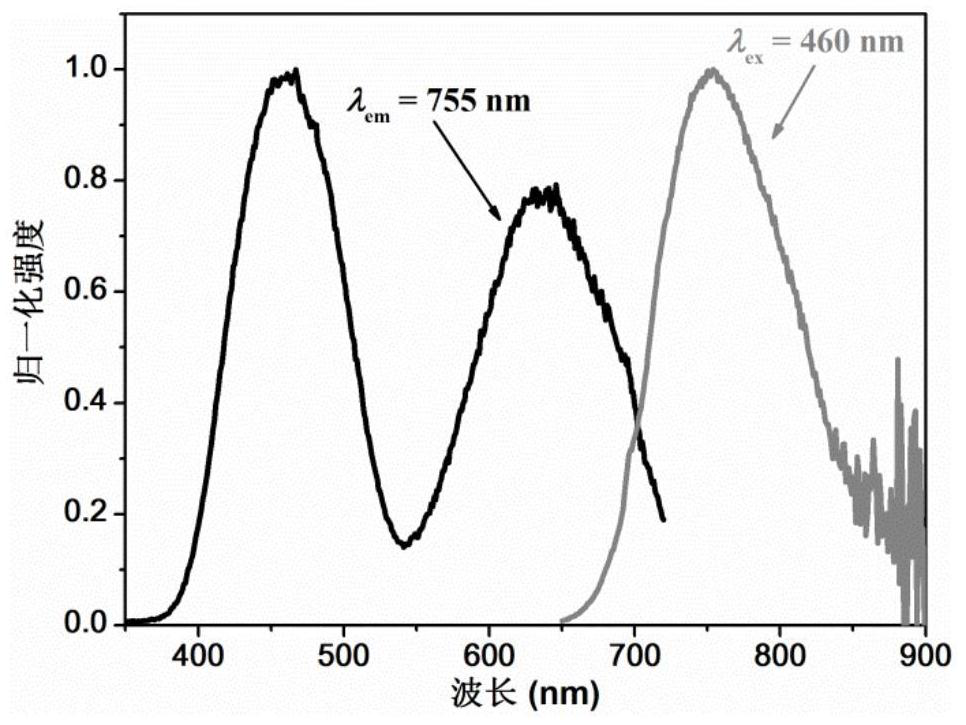

[0045] Such as figure 2 Shown are the excitation and emission spectra of the sample...

Embodiment 2

[0048] Preparation of Gd 3 Al 1.97 Cr 0.03 Ga 3 o 12 :

[0049] Press Gd 3 Al 1.97 Cr 0.03 Ga 3 o 12 The molar mass ratio of each element in the medium, accurately weigh the high-purity Gd 2 o 3 , Cr 2 o 3 , Ga 2 o 3 , Al 2 o 3 , and 3 wt% H 3 BO 3 As a flux, the mixed powder is obtained after fully grinding; the obtained mixed powder is sintered at 1350°C in the air for 6 hours, and after cooling down, it is properly ground, and then sintered again at 1350°C in the air for 6 hours; after cooling, the obtained sintered product is Grinding, washing, and grading treatment can obtain the desired near-infrared luminescent material.

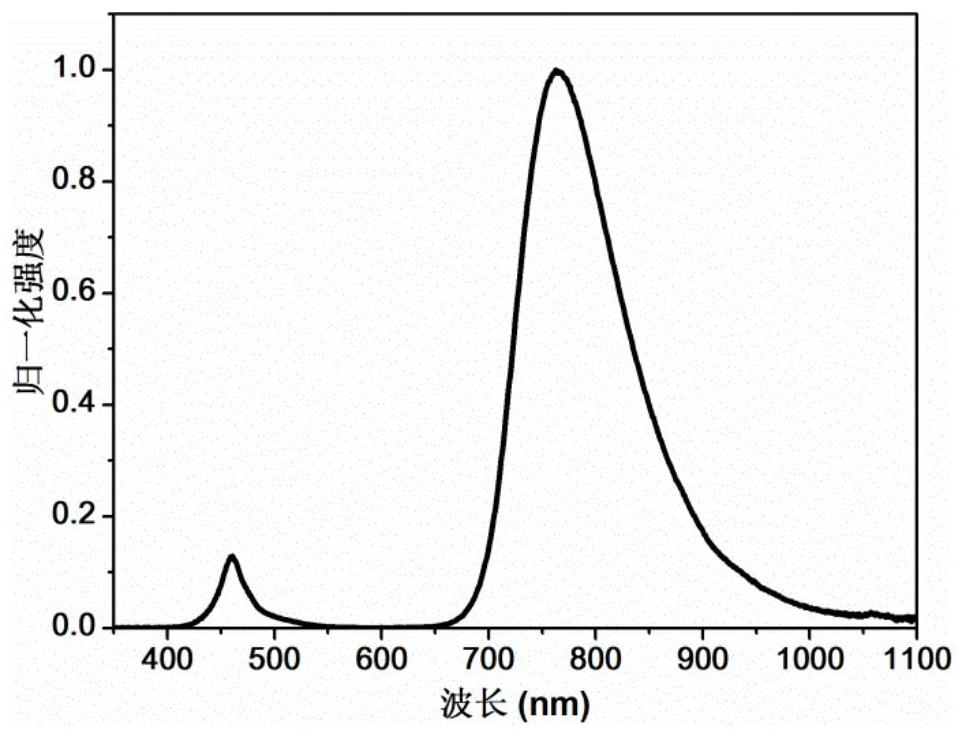

[0050] Such as Figure 4 Shown is the excitation and emission spectra of the sample of this embodiment. From attached Figure 4 It can be seen that the phosphor is excited in the blue light of 400-500nm and the red light region of 600-700nm in the visible light band, and emits broadband near-infrared light with a peak wavelength ...

Embodiment 3

[0056] The chemical formulas of the near-infrared luminescent materials in Examples 3-13 are shown in Table 1 below. The preparation method of the materials in each embodiment is similar to that of Embodiment 1. It is only necessary to weigh the raw materials according to the molar mass ratio of each element in the luminescent material of each embodiment, and carry out mixing, grinding, and sintering. The sintering temperature can be adjusted appropriately to obtain Obtaining a single crystal phase means obtaining the desired near-infrared luminescent material. The luminescent properties of the luminescent materials obtained in each example were characterized, and the results are shown in Table 1 below.

[0057] It can be known from Table 1 that the near-infrared luminescent material of the present invention has high luminous intensity and adjustable emission wavelength. Example 2 Compared with the comparative example, the Al element is used to replace the Sc element in the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com