One-dimensional metal oxide/carbide composite material and preparation method thereof

A composite material and oxide technology, applied in the field of inorganic nano functional material synthesis, can solve the problems of high energy consumption, complex synthesis process, lack of catalysis, adsorption and electrochemical activity, etc., and achieves low energy consumption, simple preparation method, Effects of favorable structural properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A preparation method of a one-dimensional metal oxide / carbide composite material, comprising the steps of:

[0046] a. Preparation of one-dimensional strip metal-organic framework materials:

[0047] Take Ni(NO 3 ) 2 ·6H 2 Add O (1.2mM) into 6mL of water, then add 12mL of 4,4'-biphenyldicarboxylic acid (1.2mM) and sodium hydroxide (2.4mM) into the aqueous solution under stirring, stir well, and put it into the reaction kettle , treated at 170°C for 12 hours, centrifuged, washed, and dried to obtain a one-dimensional strip-shaped metal-organic framework material.

[0048] b. Preparation of one-dimensional metal oxide / carbide composites:

[0049] Put the one-dimensional strip metal-organic framework material prepared in step a into a porcelain cup, transfer it into a tube furnace, feed it with oxygen, raise the temperature to 400°C at a rate of 10°C / min, calcinate for 2 hours, and wait for cooling Finally, a fluffy black powder is obtained, which is a one-dimensional...

Embodiment 2

[0051] A preparation method of a one-dimensional metal oxide / carbide composite material, comprising the steps of:

[0052] a. Preparation of one-dimensional strip metal-organic framework materials:

[0053] Take Ni(NO 3 ) 2 ·6H 2 O(0.6mM), Co(NO 3 ) 2 ·6H 2 Add O (0.6mM) into 6mL of water, then add 12mL of 4,4'-biphenyl dicarboxylic acid (1.2mM) and sodium hydroxide (2.4mM) into the aqueous solution under stirring, stir well, and put it into the reaction kettle , treated at 170°C for 12 hours, centrifuged, washed, and dried to obtain a one-dimensional strip-shaped metal-organic framework material.

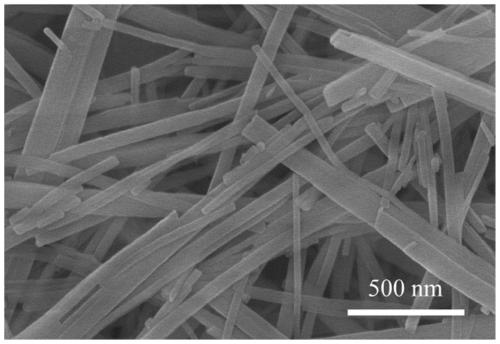

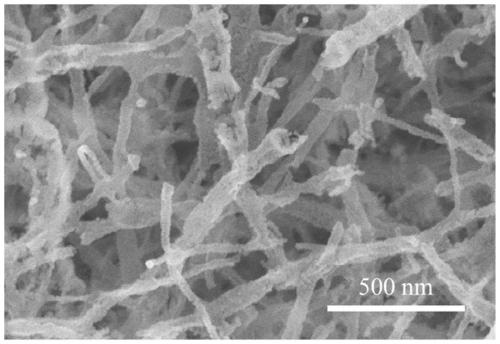

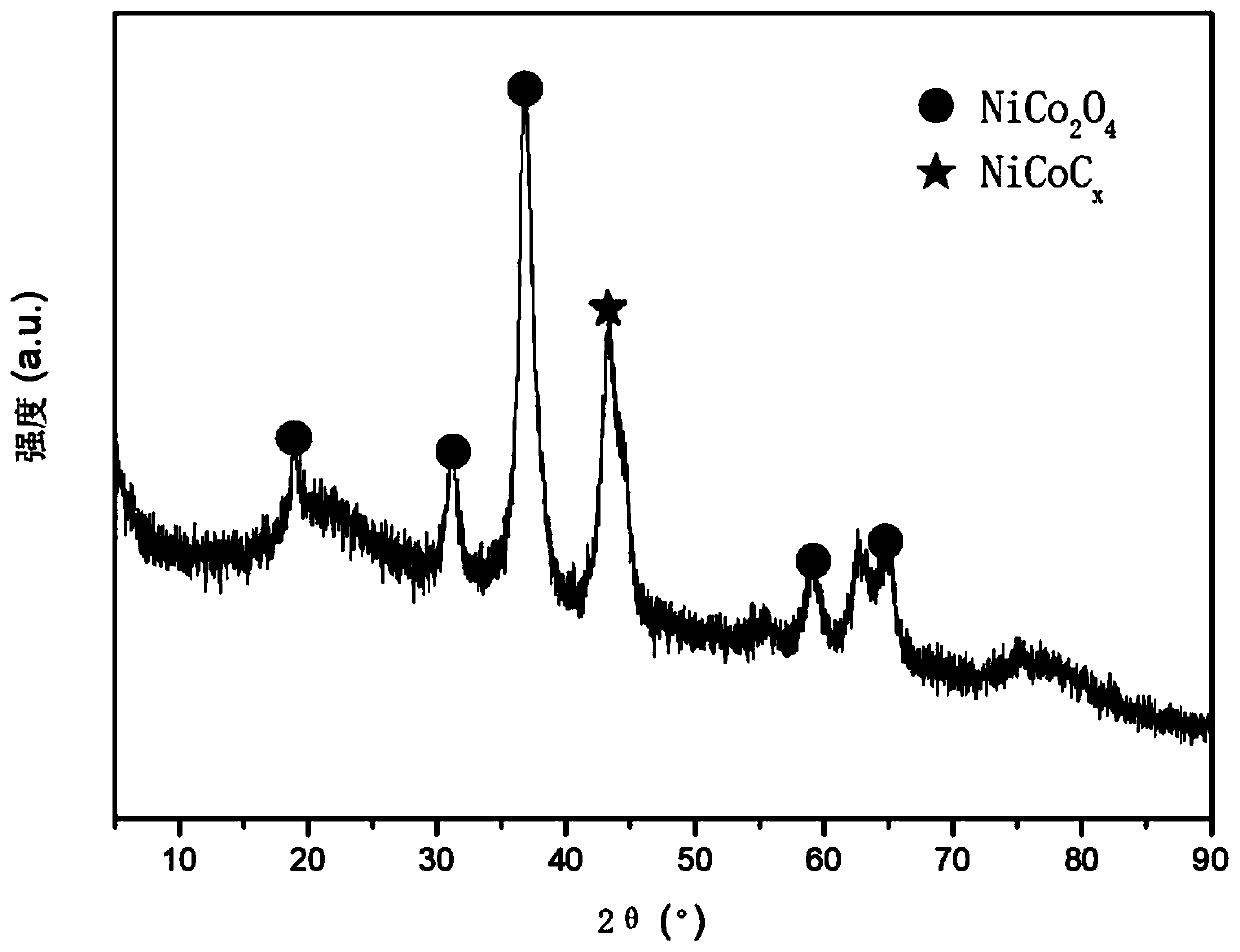

[0054] The SEM (scanning electron microscope) picture of the above-mentioned one-dimensional strip metal-organic framework material is shown in figure 1 ;Depend on figure 1 It can be seen that it is a nano-ribbon structure, the length is on the micrometer scale, the width and thickness are on the nanometer scale, the aspect ratio is ≥ 10, and there is a certain scale (50-...

Embodiment 3

[0060] A preparation method of a one-dimensional metal oxide / carbide composite material, comprising the steps of:

[0061] a. Preparation of one-dimensional strip metal-organic framework materials:

[0062] Take Ni(NO 3 ) 2 ·6H 2 O(0.3mM), Co(NO 3 ) 2 ·6H 2 Add O (0.9mM) into 6mL of water, then add 12mL of 4,4'-biphenyl dicarboxylic acid (2.4mM) and sodium hydroxide (2.4mM) into the aqueous solution under stirring, stir evenly, and put it into the reaction kettle , treated at 170°C for 8 hours, centrifuged, washed, and dried to obtain a one-dimensional strip-shaped metal-organic framework material.

[0063] b. Preparation of one-dimensional metal oxide / carbide composites:

[0064] Put the one-dimensional strip-shaped metal-organic framework material prepared in step a into a porcelain cup, transfer it into a tube furnace, pass in air, and heat it up to 500°C at a heating rate of 20°C / min for 1 hour and wait for cooling Finally, a one-dimensional metal oxide / carbide com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com