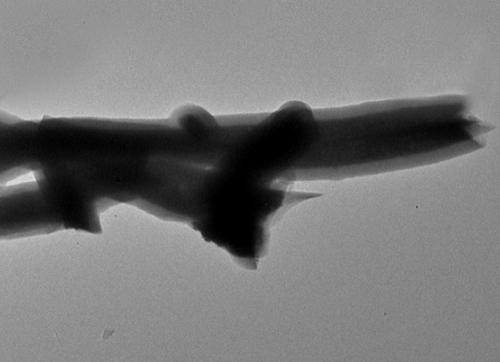

Strontium titanate polypyrrole nanocomposite fiber with one-dimensional core-shell structure and preparation method

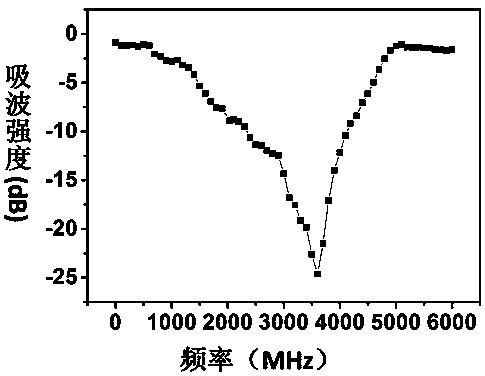

A nano-composite fiber, core-shell structure technology, applied in fiber processing, fiber chemical characteristics, conjugated synthetic polymer man-made filaments, etc., can solve the problem of narrow absorption frequency band, and achieve the expansion of absorption frequency band, uniform size distribution, The effect of simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for preparing strontium titanate / polypyrrole nanocomposite fibers with a one-dimensional core-shell structure, the steps are as follows:

[0021] (1) Preparation of strontium titanate nanofibers by electrospinning method: according to SrCO 3 The ratio of the amount of titanium tetraisopropoxide to the substance is 1:1. Weigh the raw materials, dissolve the raw materials in dilute hydrochloric acid with a volume fraction of 2%, add high polymer PVP to prepare spinning solution, high polymer PVP and The mass ratio of dilute hydrochloric acid is 1:2; the spinning solution is added to a spinning machine for spinning to prepare composite nanofibers, and the composite nanofibers are put into a muffle furnace for heat treatment to obtain strontium titanate nanofibers;

[0022] (2) Add ferric chloride and polyvinylpyrrolidone to alcohol to form a uniform solution, and disperse strontium titanate nanofibers into the above solution, and the ferric chloride, polyvinylpyrr...

Embodiment 2

[0027] A method for preparing strontium titanate / polypyrrole nanocomposite fibers with a one-dimensional core-shell structure, the steps are as follows:

[0028] (1) Preparation of strontium titanate nanofibers by electrospinning method: according to SrCO 3 The ratio of the amount of titanium to tetraisopropoxide is 1:1. Weigh the raw materials, dissolve the raw materials in dilute hydrochloric acid with a volume fraction of 4%, add high polymer PVP to prepare spinning solution, high polymer PVP and The mass ratio of dilute hydrochloric acid is 1:3; the spinning solution is added to a spinning machine for spinning to prepare composite nanofibers, and the composite nanofibers are put into a muffle furnace for heat treatment to obtain strontium titanate nanofibers;

[0029] (2) Ferric chloride and polyvinylpyrrolidone will be added to alcohol to form a uniform solution, and strontium titanate nanofibers will be dispersed into the above solution. The ferric chloride, polyvinylpyr...

Embodiment 3

[0032] A method for preparing strontium titanate / polypyrrole nanocomposite fibers with a one-dimensional core-shell structure, the steps are as follows:

[0033] (1) Preparation of strontium titanate nanofibers by electrospinning method: according to SrCO 3 The ratio of the amount of titanium tetraisopropoxide to the substance is 1:1. Weigh the raw materials, dissolve the raw materials in dilute hydrochloric acid with a volume fraction of 5%, add high polymer PVP to prepare spinning solution, high polymer PVP and The mass ratio of dilute hydrochloric acid is 1:4; the spinning solution is added to a spinning machine for spinning to prepare composite nanofibers, and the composite nanofibers are put into a muffle furnace for heat treatment to obtain strontium titanate nanofibers;

[0034] (2) Ferric chloride and polyvinylpyrrolidone will be added to alcohol to form a uniform solution, and strontium titanate nanofibers will be dispersed into the above solution. The ferric chloride...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com