A kind of silkworm moth/mulberry leaf composite superfine powder and preparation method thereof

A technology of mulberry leaf powder and superfine powder, which is applied in the direction of pharmaceutical formulations, medical preparations containing active ingredients, plant/algae/fungus/moss ingredients, etc. It can solve the problems of unfavorable absorption and utilization of nutrients and bioactive substances, high cost Reduce the nutritional value of silkworm moth protein and other problems, achieve good health care function and biological activity, avoid the reduction of biological activity, and realize the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The preparation of embodiment 1 silkworm moth / mulberry leaf composite superfine powder, silkworm moth powder

[0053] 1. Preparation of silkworm moth / mulberry leaf composite superfine powder:

[0054] S1. Take the fresh silkworm moth, rinse the moth body with clear water, remove the scales, and clean the moth body;

[0055] S2. drying the silkworm moths treated in S1 at 60° C. for 4 hours to obtain dried silkworm moths;

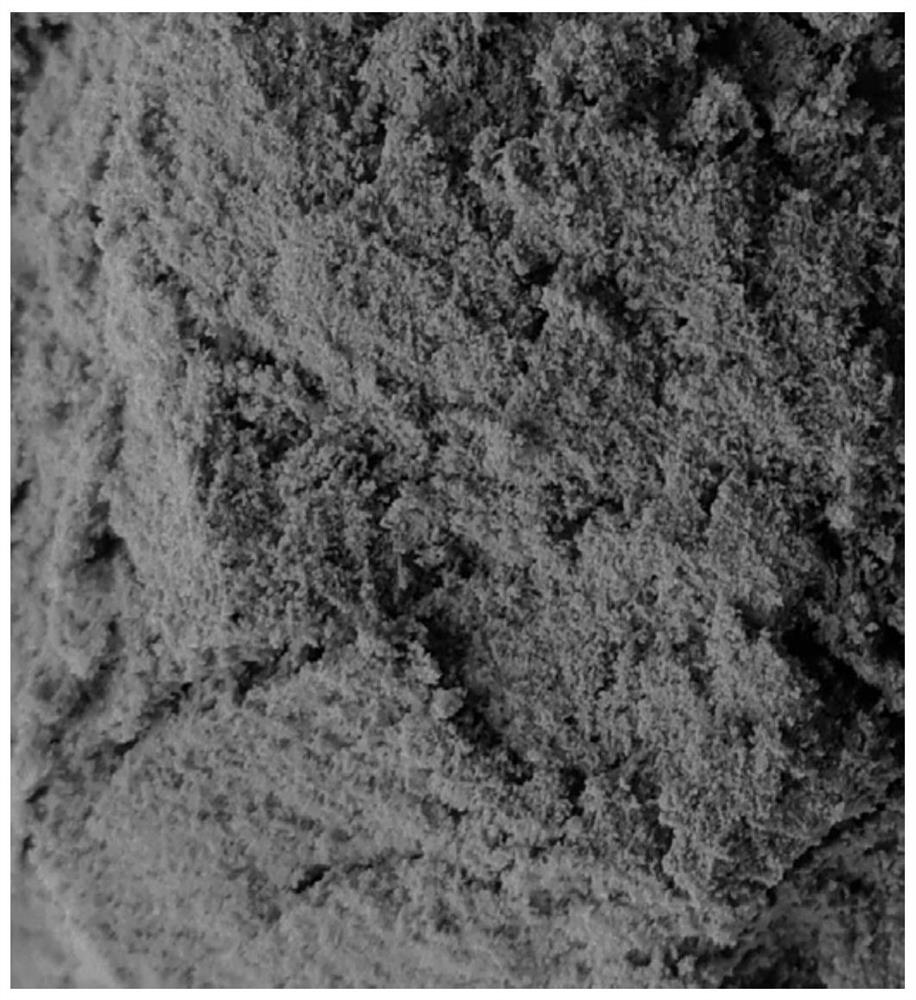

[0056] S3. pulverize the dried silkworm moth with a pulverizer to obtain silkworm moth meal;

[0057] S4. Take Kangqing No. 10 mulberry leaves, dry them and grind them into 200 mesh mulberry leaf powder;

[0058] S5. Mix silkworm moth meal and mulberry leaf powder in a mass ratio of 1:1, dry until the moisture content is 5%, and obtain silkworm moth / mulberry leaf compound powder;

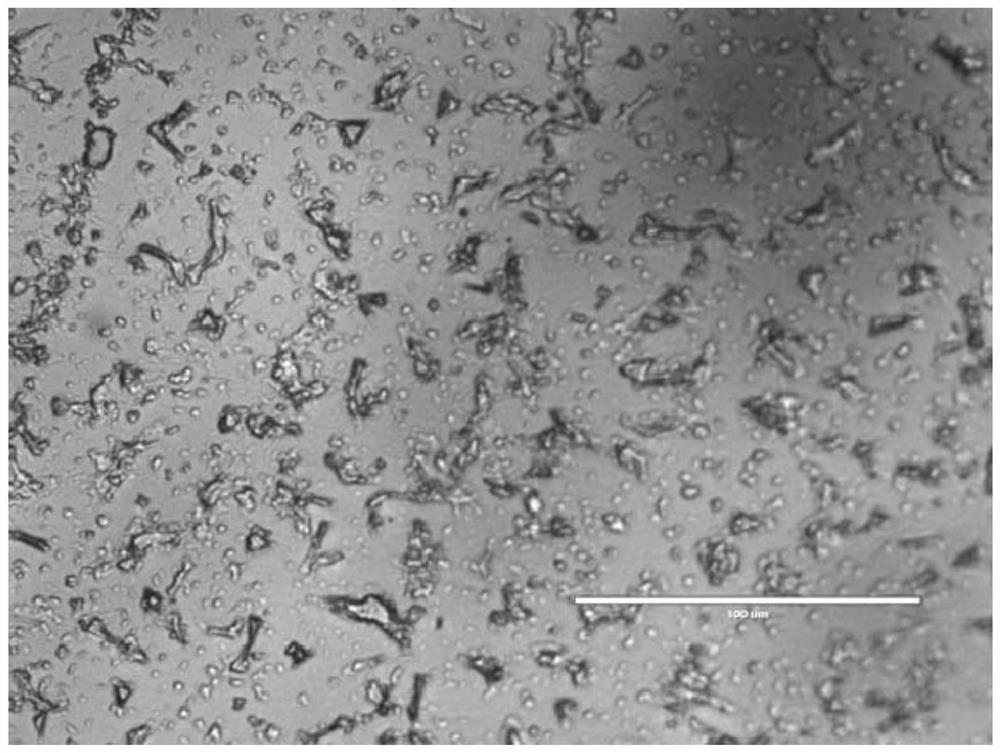

[0059] S6. The silkworm moth / mulberry leaf compound powder obtained in step S5 is pulverized by a nano pulverizer under the condition of 0° C. to prepare the silkworm mot...

Embodiment 2

[0082] The preparation of embodiment 2 silk moth / mulberry leaf composite superfine powder

[0083] S1. Take the fresh silkworm moth after seed production, rinse the moth body with clear water, remove the scales, and clean the moth body;

[0084] S2. drying the silkworm moths treated in S1 at 50° C. for 5 hours to obtain dried silkworm moths;

[0085] S3. pulverize the dried silkworm moth with a pulverizer to obtain silkworm moth meal;

[0086] S4. Take Kangqing No. 10 mulberry leaves, dry them and grind them into 100 mesh mulberry leaf powder;

[0087] S5. Mix silkworm moth meal and mulberry leaf powder in a mass ratio of 1:2, dry until the water content is 4%, and obtain silkworm moth / mulberry leaf compound powder;

[0088] S6. The silkworm moth / mulberry leaf compound powder obtained in step S5 is pulverized by a nano pulverizer under the condition of -10° C. to prepare the silkworm moth / mulberry leaf composite superfine powder.

[0089] The average particle diameter of th...

Embodiment 3

[0090] The preparation of embodiment 3 silkworm moth / mulberry leaf composite superfine powder

[0091] S1. Take the fresh silkworm moth after seed production, rinse the moth body with clear water, remove the scales, and clean the moth body;

[0092] S2. drying the silkworm moths treated in S1 at 60° C. for 4 hours to obtain dried silkworm moths;

[0093] S3. pulverize the dried silkworm moth with a pulverizer to obtain silkworm moth meal;

[0094] S4. Take Kangqing No. 10 mulberry leaves, dry them and grind them into 200 mesh mulberry leaf powder;

[0095] S5. Mix silkworm moth meal and mulberry leaf powder in a mass ratio of 1:1, dry until the moisture content is 5%, and obtain silkworm moth / mulberry leaf compound powder;

[0096] S6. The silkworm moth / mulberry leaf compound powder obtained in step S5 is pulverized by a nano pulverizer under the condition of 10° C. to prepare the silkworm moth / mulberry leaf composite superfine powder.

[0097] Similarly, the average partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com