Threaded core welding rod

A thread and welding core technology, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems such as the difficulty in filling the pores evenly, the eccentricity of the internal air residual electrode, and the difficulty in ensuring the rigidity of the welding core, etc., to achieve Wide melting width, reduced welding current and high welding current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

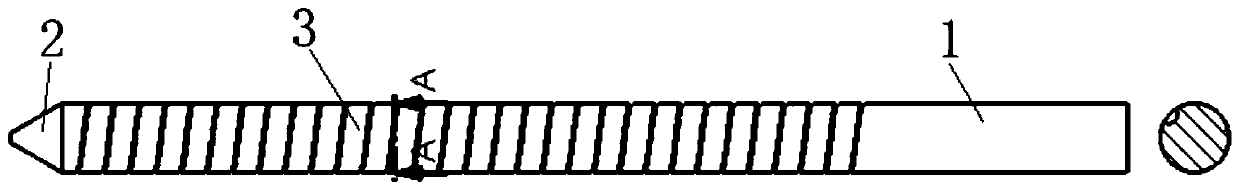

[0031] see figure 1 , as shown in the legend, the chemical composition of the welding core is mainly carbon (C) 0.15%, manganese (Mn) 1.25%, silicon (Si) 0.90%, sulfur (S) 0.035%, phosphorus (P) 0.035%, nickel (Ni) 0.30%, chromium (Cr) 0.20%, molybdenum (Mo) 0.30%, vanadium (V) 0.08%, iron (Fe) balance. The thread gap and the periphery are coated with alkaline coating. The nominal diameter of the thread is 6mm, the thread height is 0.75mm, the pitch is 2mm, and the thread shape is semicircle. After the peripheral coating is coated, the total diameter of the electrode can reach more than 7mm.

Embodiment 2

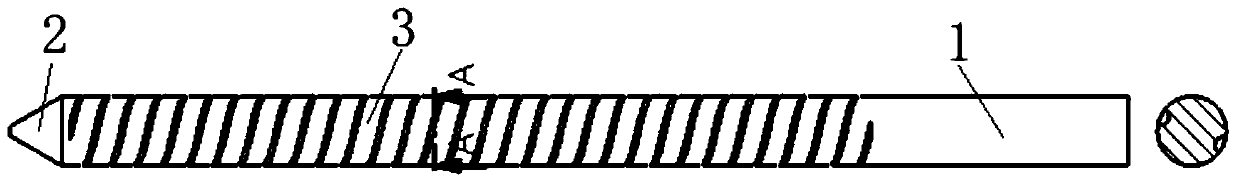

[0033] see figure 2 , as shown in the legend, the chemical composition of the welding core is mainly carbon (C) 0.12%, manganese (Mn) 0.04-1.6%, silicon (Si) 0.80%, sulfur (S) 0.030%, phosphorus (P) 0.020% , nickel (Ni) 0.25%, chromium (Cr) 0.15%, molybdenum (Mo) 0.35%, vanadium (V) 0.05%, iron (Fe) balance. The thread gap and the periphery are coated with alkaline coating. The nominal diameter of the thread is 4mm, the thread height is 0.5mm, the pitch is 3mm, and the tooth shape is semicircle. After the peripheral coating is coated, the total diameter of the electrode can reach more than 5mm.

Embodiment 3

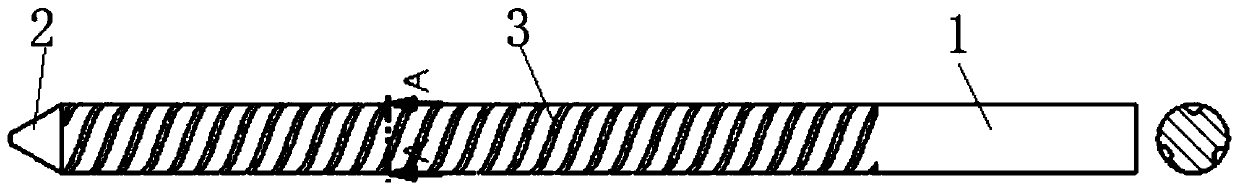

[0035] see image 3, as shown in the legend, the chemical composition of the welding core is mainly carbon (C) 0.08%, manganese (Mn) 0.5-2.5%, silicon (Si) 1.00%, sulfur (S) 0.030%, phosphorus (P) 0.040% , nickel (Ni) 9.0-11.0%, chromium (Cr) 18.0-21.0%, molybdenum (Mo) 0.75%, copper (Cu) 0.75%, niobium tantalum (Nb+Ta) 8*C-1.00%, iron (Fe )margin. The thread gap and the periphery are coated with alkaline coating. The nominal diameter of the thread is 3.2mm, the thread height is 0.5mm, the pitch is 4.5mm, and the thread shape is semicircle. After the peripheral coating is coated, the total diameter of the electrode can reach more than 4mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal diameter | aaaaa | aaaaa |

| Overall diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com