Preparation process of titanium-based tin-iridium-series oxide coated electrode

A technology of oxide coating and preparation process, which is applied in the direction of metal material coating process, coating, water pollutants, etc., can solve the problem of low efficiency of electrochemical indirect oxidation current, prone to oxygen evolution reaction, short anode life, etc. problems, to achieve the effect of improving the electrochemical activity of chlorine analysis, low chlorine analysis potential and uniform surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] like Figures 1 to 4 Shown is an embodiment of the preparation process of a titanium-based tin-iridium oxide coating electrode of the present invention, including electrode substrate production, coating solution preparation and electrode substrate coating treatment; wherein, the electrode substrate is titanium plate, the preparation of the coating solution is a mixed solution prepared in a predetermined ratio of isopropanol and hydrochloric acid as a solvent, respectively dissolving H 2 IrCl 6 ·6H 2 O, SnCl 4 ·5H 2 O, RuCl 3 while obtaining a predetermined concentration of H 2 IrCl 6 ·6H 2 Alcohol solution of O, SnCl 4 ·5H 2 Alcohol solution of O, RuCl 3 Alcohol solution, and three kinds of alcohol solutions are mixed to make the coating solution, and the molar ratio of elements in the coating solution is Sn:Ru:Ir=0.7:0~0.3:0~0.3 The electrode substrate coating treatment is to use the coating solution to sequentially coat, dry and sinter the electrode substr...

Embodiment 2

[0049] (a) One of the preparation schemes of Sn-Ru-Ir electrodes

[0050] According to the amount of elemental substances Sn:Ru:Ir=0.7:0:0.3, mix tin tetrachloride, ruthenium trichloride, and chloroiridate isopropoxide solution in proportion to prepare a coating solution, and use a small brush to apply it on the titanium substrate Brush evenly on the top of the paint, dry at 80°C for 10 minutes, let the solvent volatilize slowly, then place it in a resistance furnace, bake at 450°C for 10 minutes, cool to room temperature and do the next brushing, repeat brushing more than 10 times, Roasting for the last time for 1h.

[0051] (b) The second preparation scheme of Sn-Ru-Ir electrode

[0052] According to the amount of elemental substances Sn: Ru: Ir = 0.7: 0.01: 0.29, mix tin tetrachloride, ruthenium trichloride, and chloroiridate isopropoxide solution in proportion to prepare a coating solution, and use a small brush on the titanium substrate Brush evenly on the top of the pa...

Embodiment 3

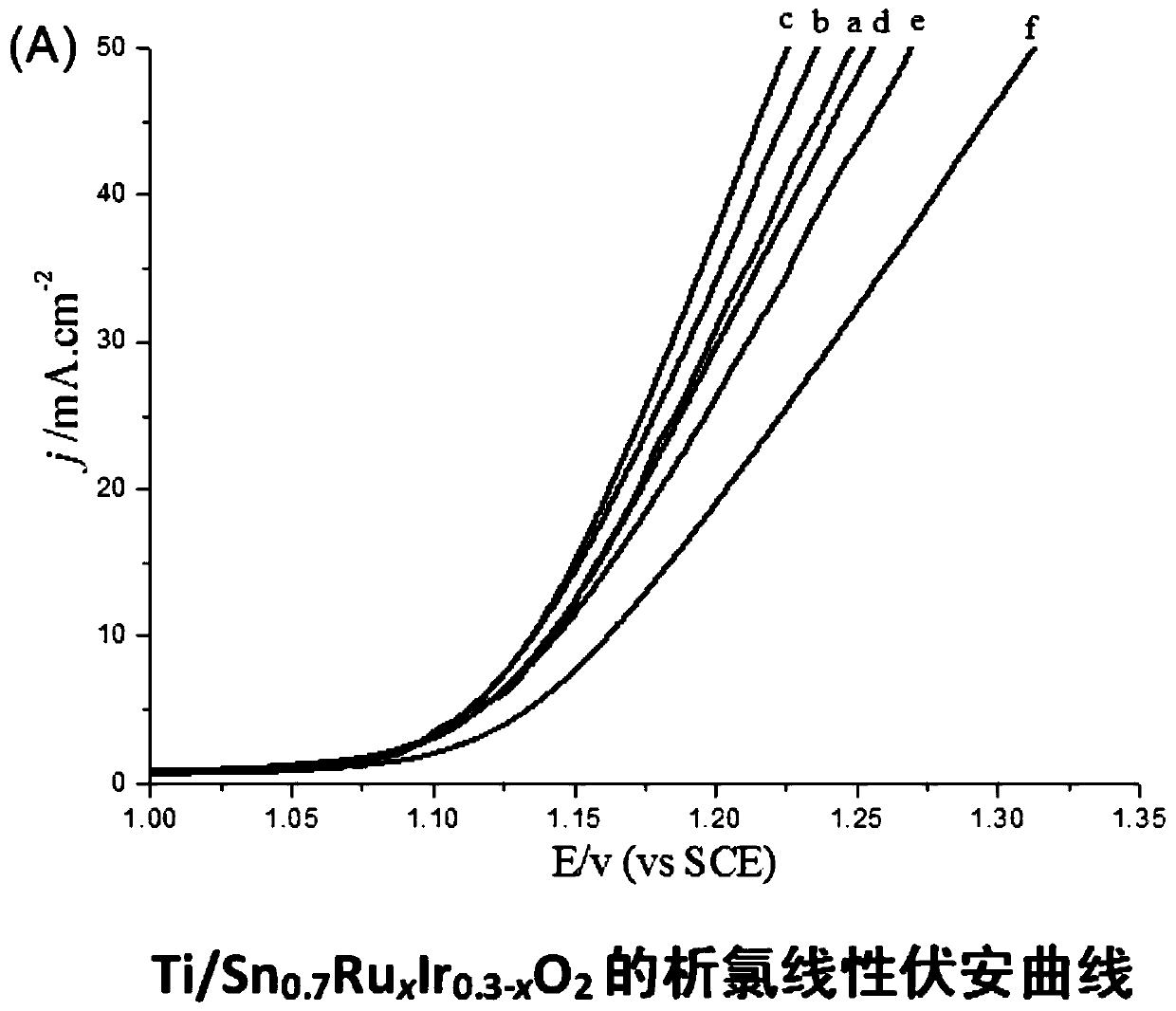

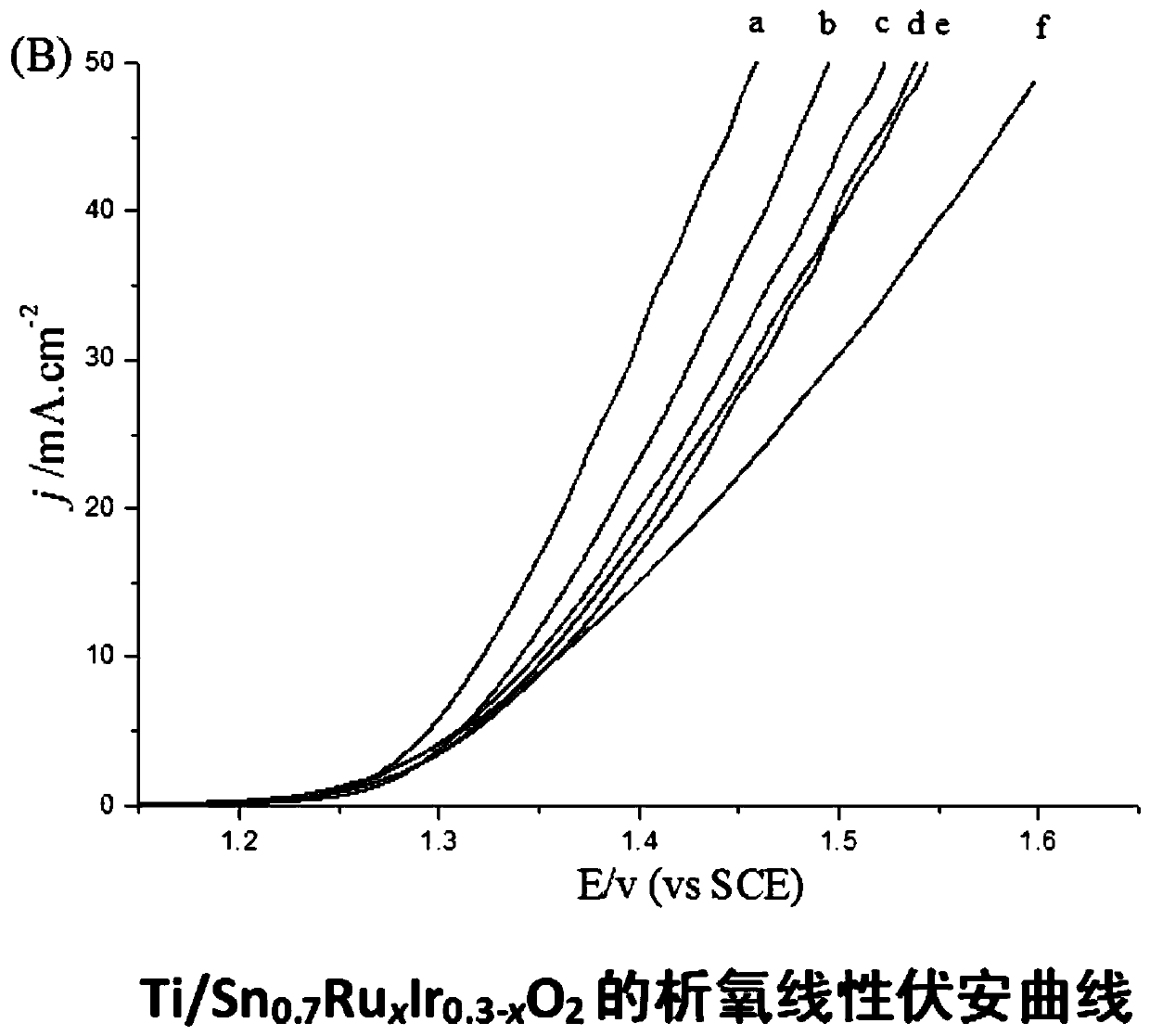

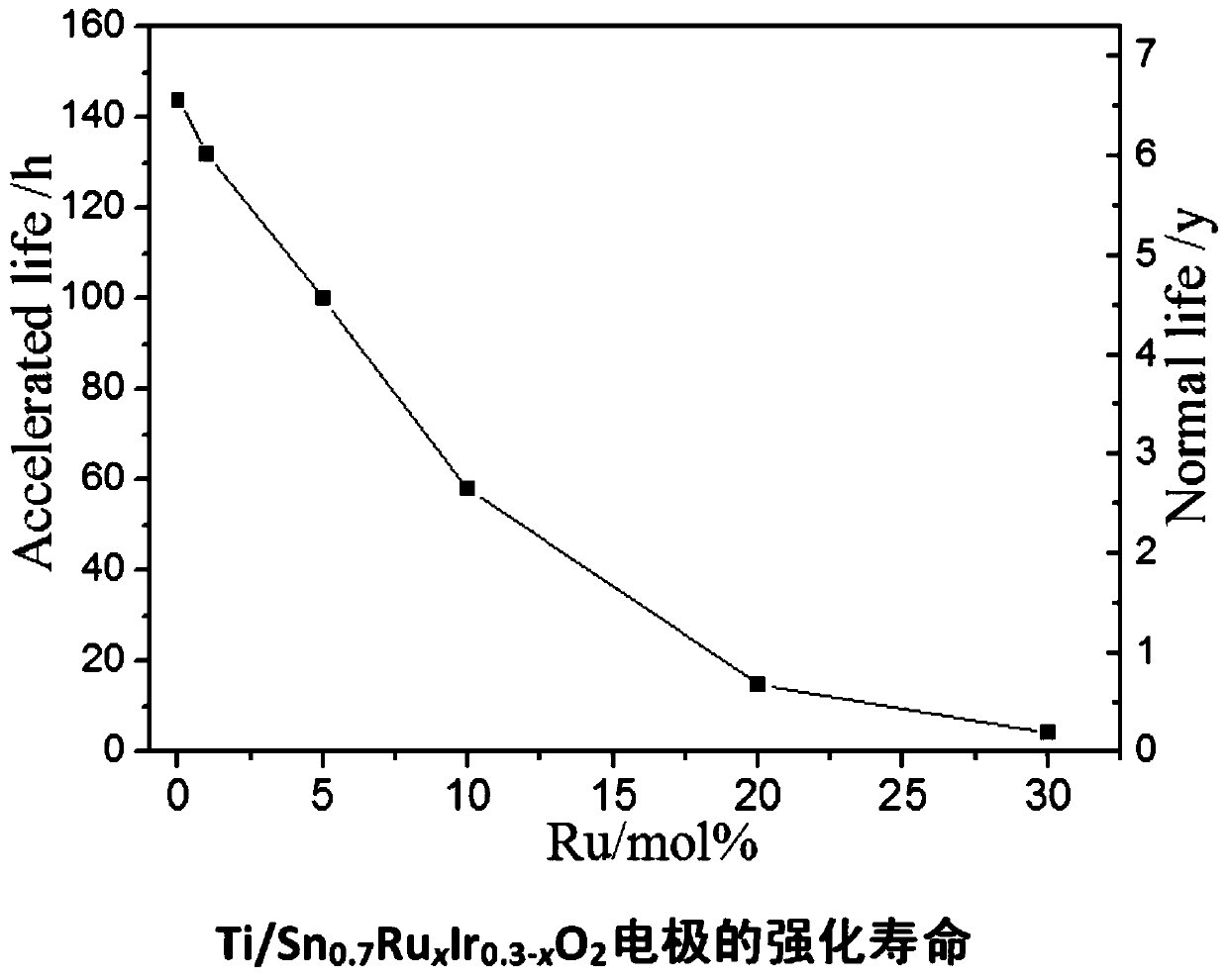

[0062] The titanium-based tin-iridium series oxide coating electrode prepared in above-mentioned embodiment 1 and 2 is tested, and its chlorine evolution linear voltammetry curve is measured as follows: figure 1 As shown, the measured oxygen evolution linear voltammetry curve is as follows figure 2 As shown, the measured strengthening life curve is as follows image 3 shown.

[0063] The test results of the prepared titanium-based tin-iridium oxide coating electrode show that: with the increase of Ru content, the chlorine evolution reaction current first increases and then decreases, while the oxygen evolution reaction current decreases continuously. The addition of Ru can improve the electrochemical activity of chlorine evolution of the tin-iridium oxide electrode and inhibit the occurrence of oxygen evolution reaction; when the Ru content is 0.05, the chlorine evolution current is the largest, and with the increase of the chlorine evolution current, the change of the chlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com