Method for separating phorbol alcohol by ultrasonic-assisted alcoholysis-extraction coupling technology

A technology of ultrasonic wave and phorbol alcohol, which is applied in the field of ultrasonic-assisted alcoholysis-extraction coupling technology to separate phorbol alcohol. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

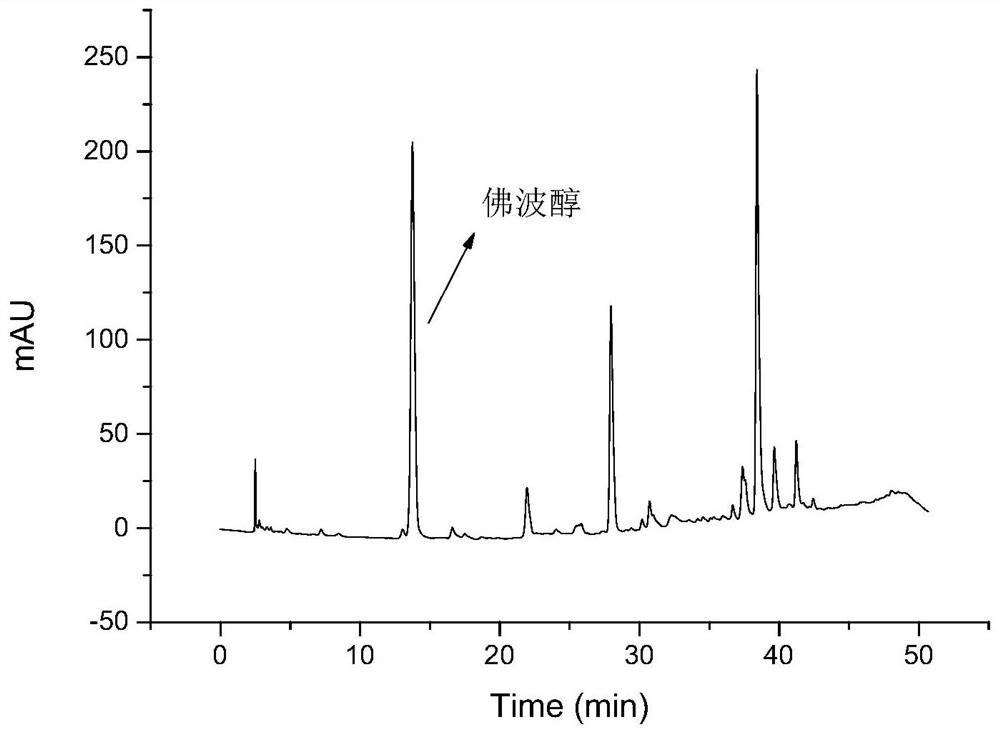

Image

Examples

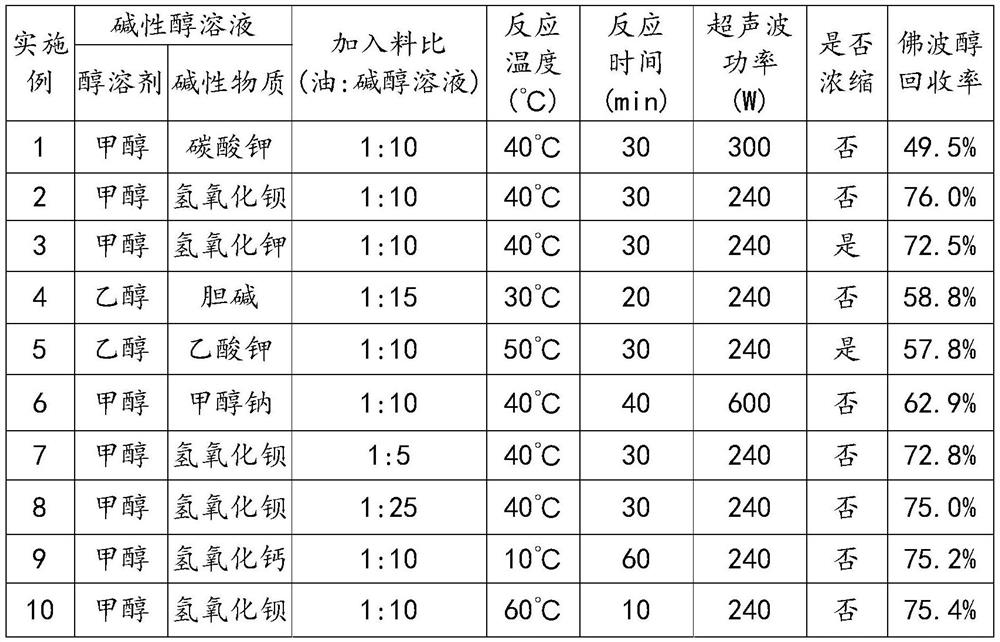

Embodiment 1

[0027] Preparation of S1 saturated alkaline methanol solution: add a sufficient amount of anhydrous potassium carbonate to methanol with a content ≥ 99%, reflux in a water bath at 70°C for 2 hours, and prepare a potassium carbonate-methanol saturated solution for later use;

[0028] Preparation of S2 acidic methanol solution: Add 10% volume concentrated hydrochloric acid to methanol with a volume content ≥ 99% and mix evenly to form a hydrochloric acid-methanol mixed solution for later use;

[0029] S3 Alcoholysis-extraction: Precisely measure 1ml of croton oil and put it in a 15ml centrifuge tube, add potassium carbonate-methanol saturated solution according to the ratio of solid to liquid 1:10, shake and shake well, under the condition of ultrasonic power of 300W and temperature of 40℃ Under extraction for 30min. Standing and separating to obtain upper clarified liquid and lower layer oil phase liquid;

[0030] S4 adjust the pH: use a needle to take the supernatant liquid a...

Embodiment 2

[0033] Preparation of S1 saturated alkaline methanol solution: add a sufficient amount of anhydrous barium hydroxide to methanol with a content ≥ 99%, reflux in a water bath at 70°C for 2 hours, and prepare a barium hydroxide-methanol saturated solution for later use;

[0034] Preparation of S2 acidic methanol solution: Add 10% volume concentrated hydrochloric acid to methanol with a volume content ≥ 99% and mix evenly to form a hydrochloric acid-methanol mixed solution for later use;

[0035] S3 alcoholysis-extraction: Precisely measure 1ml of croton oil and place it in a 15ml centrifuge tube, add barium hydroxide-methanol saturated solution according to the ratio of solid to liquid 1:10, oscillate and shake well, in the ultrasonic power of 240W, the temperature is 40℃ Conditions for extraction of 30min. Standing and separating to obtain upper clarified liquid and lower layer oil phase liquid;

[0036] S4 repeated extraction: remove the lower oil phase liquid and continue al...

Embodiment 3

[0041] Preparation of S1 saturated alkaline methanol solution: add a sufficient amount of anhydrous potassium hydroxide to methanol with a content ≥ 99%, reflux in a water bath at 70°C for 2 hours, and prepare a saturated potassium hydroxide-methanol solution for later use;

[0042] Preparation of S2 acidic methanol solution: Add 10% volume concentrated hydrochloric acid to methanol with a volume content ≥ 99% and mix evenly to form a hydrochloric acid-methanol mixed solution for later use;

[0043] S3 Alcoholysis-extraction: Precisely measure 50ml of croton oil and put it in a 2000ml beaker, add potassium hydroxide-methanol saturated solution according to the ratio of solid to liquid 1:10, shake and shake well, under the condition of ultrasonic power of 240W and temperature of 40℃ Under extraction for 30min. Go to in the separating funnel, leave standstill to separate, obtain upper layer clarified liquid and lower layer oil phase liquid;

[0044] S4 repeated extraction: remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com