Chemical forming solution, chemical forming method and anode foil

A chemical formation method and chemical liquid technology, which are applied in anodizing, electrolytic capacitors, coatings, etc., can solve problems such as reducing specific volume, and achieve the effects of increasing specific volume, strengthening the bonding force of oxide film, and reducing the amount of oxygen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

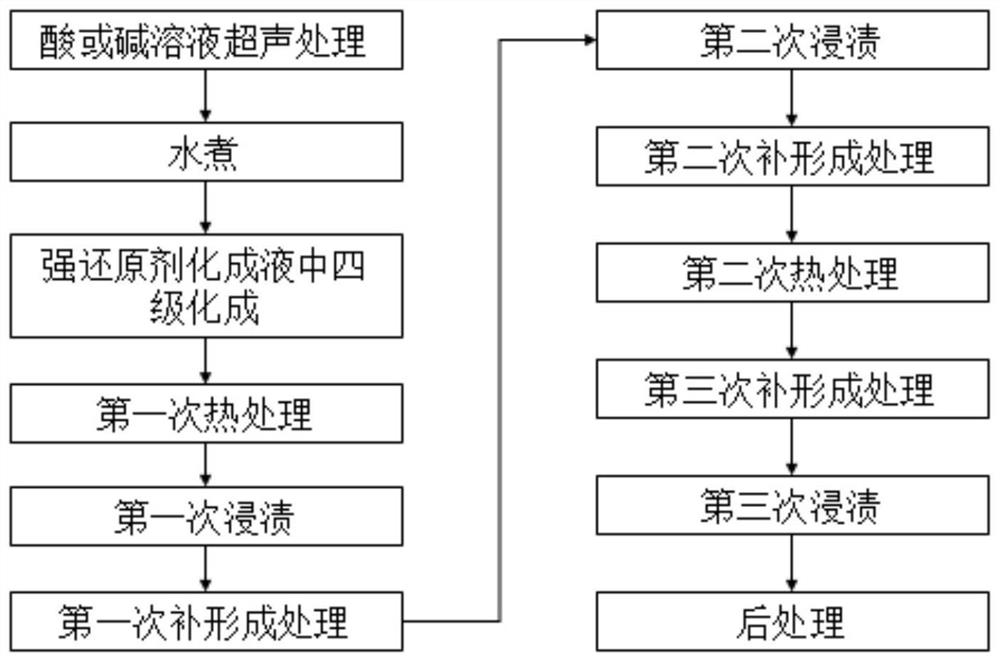

[0146] 1) Pretreatment: use a laminated foil with a thickness of 125 μm, immerse it in a nitric acid solution with a concentration of 5wt.% and a temperature of 50°C, and turn on an ultrasonic wave with a frequency of 60kHz for 4 minutes;

[0147] 2) Boil in water: wash the pre-treated foil and immerse it in pure water at 100°C for 10 minutes;

[0148] 3) Quaternary formation: anodize the boiled foil in an aqueous solution of 5wt.% boric acid + 0.6wt.% ammonium borate + 0.08wt.% ascorbic acid at 85°C with a current density of 30mA / cm 2 , the constant current boost reaches 120V, and the constant voltage is maintained for 6 minutes; then anodic oxidation treatment is performed at 85°C in an aqueous solution of 5wt.% boric acid + 0.4wt.% ammonium borate + 0.06wt.% ascorbic acid, and the current density is 30mA / cm 2 , the constant current boost reaches 320V, and the constant voltage is maintained for 8 minutes; then anodic oxidation treatment is performed at 85°C in an aqueous sol...

Embodiment 2

[0159] 1) Pretreatment: use a laminated foil with a thickness of 125 μm, immerse it in a sodium hydroxide solution with a concentration of 0.5wt.% and a temperature of 50°C, and turn on an ultrasonic wave with a frequency of 40kHz for 4 minutes;

[0160] Steps 2)-12) are the same as in Example 1.

Embodiment 3

[0162] 1) Pretreatment: use a laminated foil with a thickness of 125 μm, immerse it in a nitric acid solution with a concentration of 8wt.% and a temperature of 50°C, and turn on an ultrasonic wave with a frequency of 80kHz for 4 minutes;

[0163] Steps 2)-12) are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com