Gradient transition connection method of steel/titanium dissimilar metal based on laser synchronous preheating deposition

A dissimilar metal, gradient transition technology, applied in laser welding equipment, metal processing equipment, welding/welding/cutting items, etc., can solve the problems of poor toughness and low strength of welded joints, prevent brittle phase cracking and reduce welding heat The effect of high input and quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

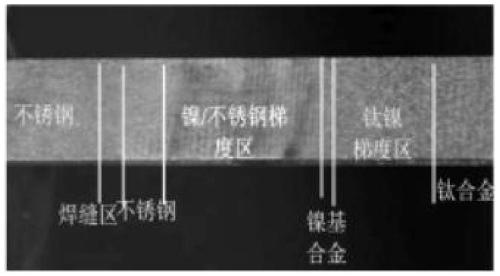

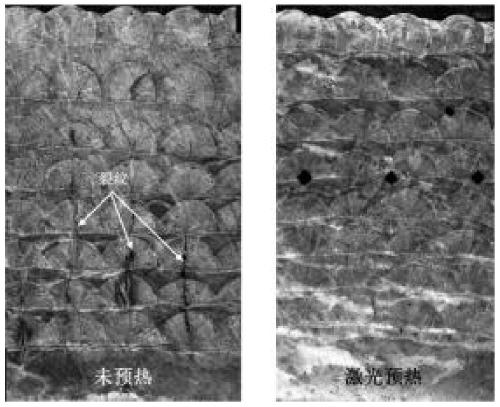

[0032] The deposition powder materials used in this embodiment are spherical 316L stainless steel, Inconel625 nickel-based alloy and Ti6Al4V alloy powder. Use 10mm thick 316L and Ti6Al4V boards as substrates, polish the substrates, and remove oil and moisture with acetone or ethanol for later use.

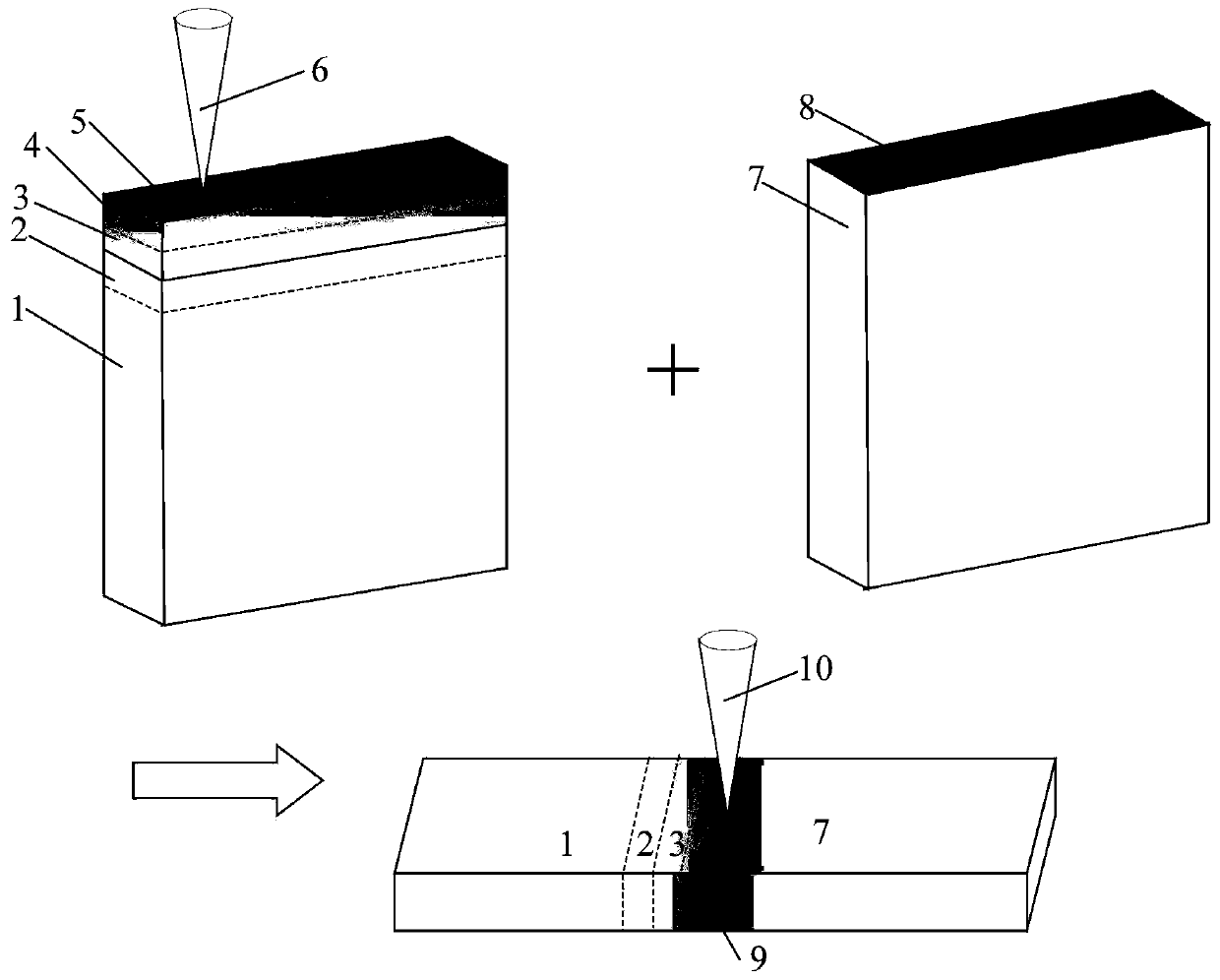

[0033]In this embodiment, a fiber laser processing system is selected for deposition and welding. The IPG10kW fiber laser with a focal length of 300mm and a wavelength of 1064nm is divided into two optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com