Porous polyimide ink, preparation method thereof, and method for preparing porous polyimide through direct writing 3D printing

A polyimide and polyamic acid technology, which is applied in the field of 3D printing technology and the preparation of porous polymer materials, can solve the problems of difficult control of porous polyimide pores and difficulty in forming porous components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention provides the preparation method of porous polyimide ink described in above-mentioned scheme, comprises the following steps:

[0036] The components of the porous polyimide ink are mixed according to the mass parts and then ball-milled to obtain the mixture;

[0037] The mixture is degassed to obtain a porous polyimide ink.

[0038] In the invention, the components of the porous polyimide ink are mixed according to the mass fraction and then ball-milled to obtain the mixed material. In the present invention, there is no special requirement on the order in which the components are added during mixing, and the mixing can be performed in any order. In the present invention, the speed of the ball milling is preferably 1000-6000r / min, more preferably 2000-4000r / min; in the present invention, the ball milling is preferably repeated until the mixture is evenly mixed. In a specific embodiment of the present invention, The ball milling is repeated at least...

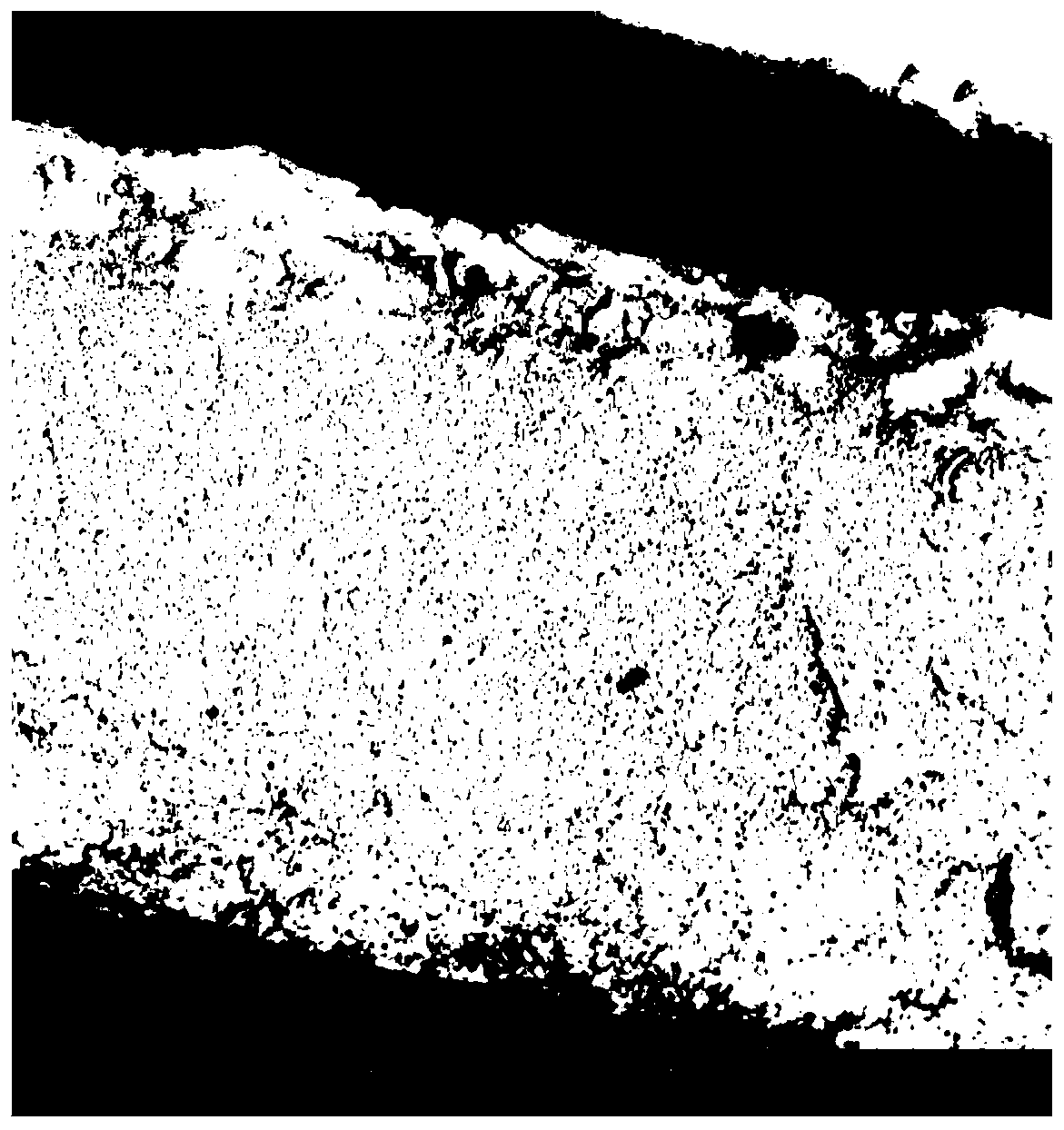

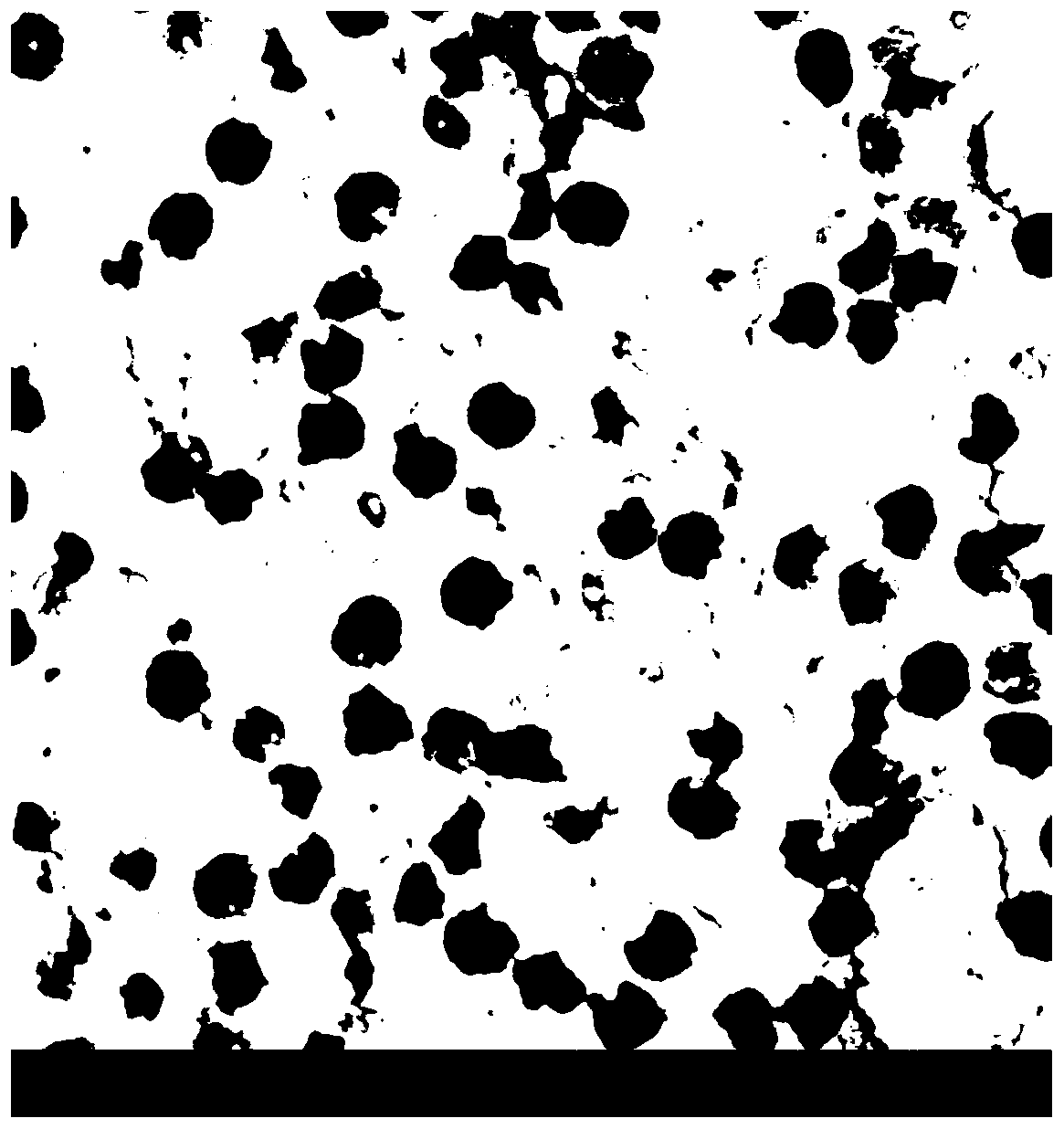

Embodiment 1

[0051] (1) Preparation of porous polyamic acid ink: 40g of 4,4'-diaminodiphenyl ether (ODA) and 64g of 4,4'-diphenyl ether dianhydride (ODPA) in 500mL of N-methyl-2 -React in pyrrolidone for 12 hours to obtain a polyamic acid solution, which forms a micron-sized film after the polyamic acid solution is coated, and then soaks it in a mixed solution of water and ethanol to form a white solid film, then sequentially drying, pulverizing and Screening to prepare polyamic acid powder with a particle size of 100-300 meshes, and the number-average molecular weight of the obtained polyamic acid is 25,000.

[0052] Take 4.5g of polyamic acid powder, 5.5g of N,N-dimethylacetamide, and 0.99g of polymethacrylate microspheres with a diameter of 3 μm, stir and mix at room temperature, and ball mill at a ball milling rate of 3000r / min for 5min, repeatedly Carry out ball milling again until the mixture is evenly mixed, put it into a vacuum chamber to evacuate for 45 minutes, and centrifuge at ...

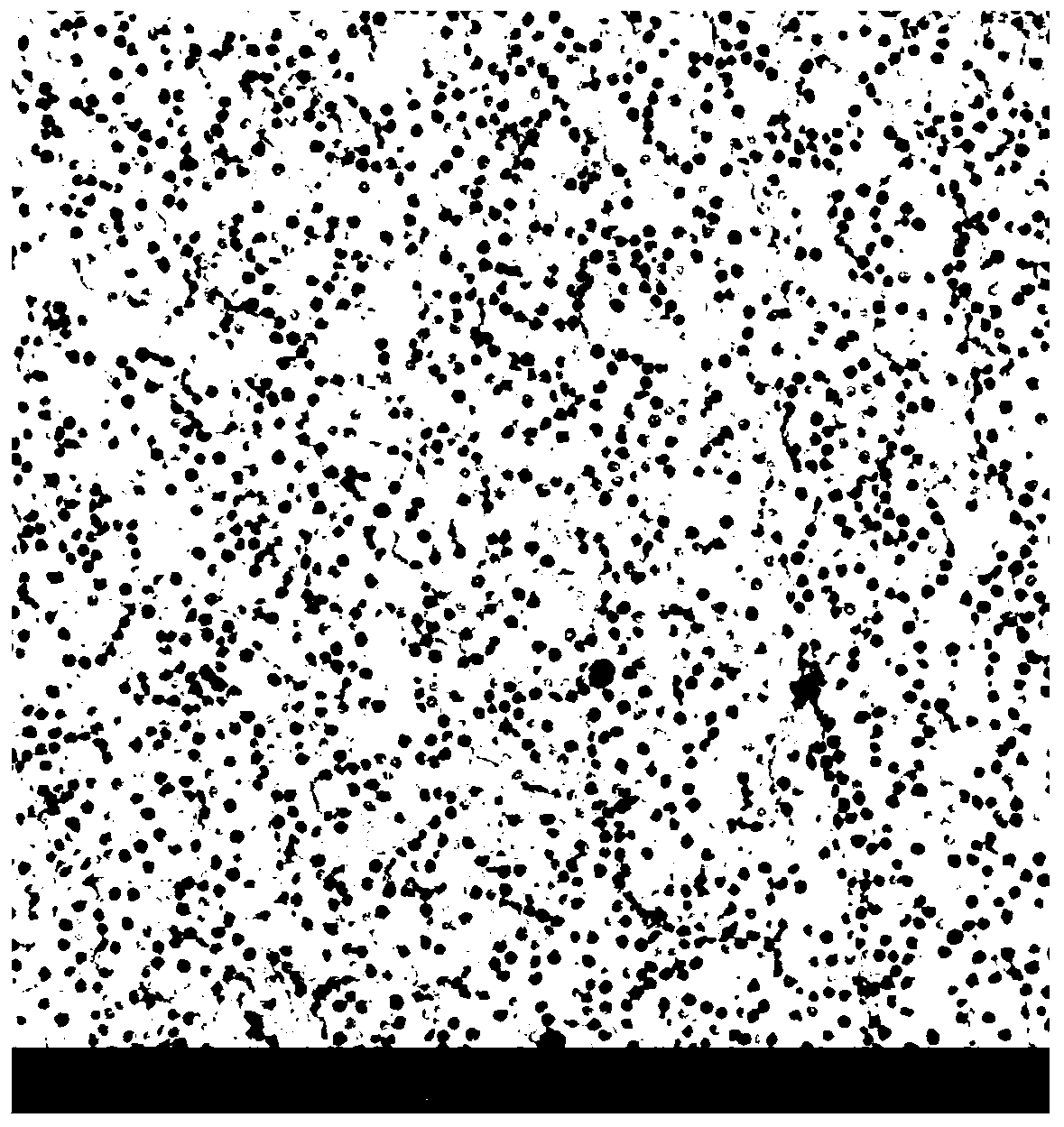

Embodiment 2

[0055] (1) Preparation of porous polyamic acid ink: Take 5.1 g of homemade polyamic acid powder (preparation method is the same as in Example 1, particle size is 100-300 mesh, number average molecular weight is 400000), N-methyl- 5.0g of 2-pyrrolidone solution, 0.76g of PS microspheres with a diameter of 2μm, stirred and mixed at room temperature, ball milled at a ball milling rate of 2800r / min for 5min, repeated ball milling until the mixture is evenly mixed, put into a vacuum chamber to evacuate After 45 minutes, centrifuge at a high speed of 6000 r / min for 12 minutes to obtain porous polyimide ink.

[0056] (2) Preparation of porous polyimide: the porous polyimide ink prepared in this example is extruded through a direct writing 3D printer to obtain a green body, which is placed in a vacuum oven for thermal imidization treatment, The heating program for thermal imidization is: 1.8°C / min to 60°C for 12h, 1.8°C / min to 100°C for 1h, 1.5°C / min to 150°C for 1h, 1.5°C / min to 200°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com