Semiconductor light-emitting element and light-emitting device

A technology for light-emitting elements and semiconductors, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as electrode shading, and achieve the effects of reducing shading, simple process, and improving uniform dispersion of light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

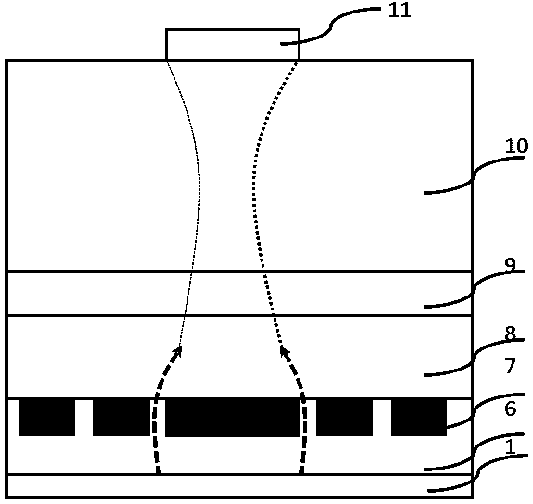

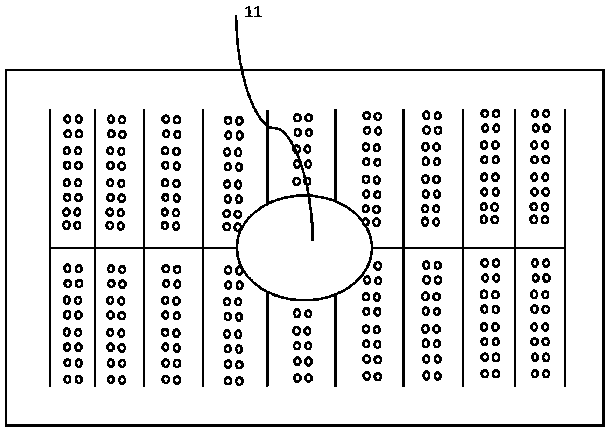

[0067] Such as figure 1 Shown is a traditional semiconductor light emitting element as described in the background art, including:

[0068] A semiconductor light emitting sequence, the semiconductor light emitting sequence includes a first conductivity type semiconductor layer 10, a light emitting layer 9 and a second conductivity type semiconductor layer 8;

[0069] A partial area on one side of the second conductivity type semiconductor layer 8 is covered by the electrical insulating layer 7 to form an electrical contact area, and a partial area on one side not covered by the electrical insulating layer 7 is an electrical contact area. The electrically insulating layer is usually silicon oxide or silicon nitride or calcium fluoride or magnesium fluoride. A plurality of openings are usually formed on the electrical insulating layer, and electrical contact areas are located within the openings.

[0070] The first electrode 11, including the main pad electrode (generally circ...

Embodiment 2

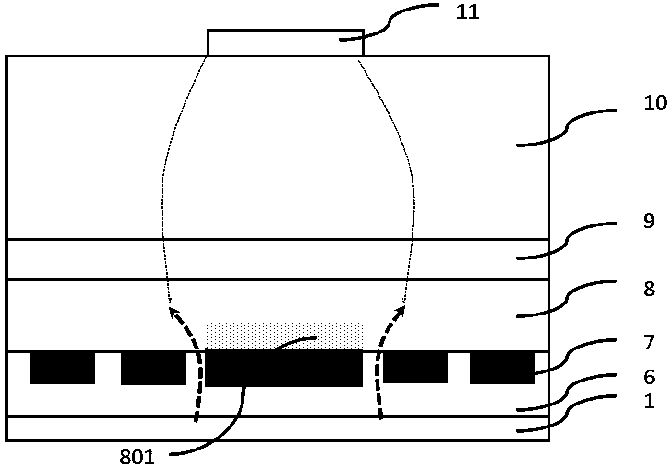

[0127] Such as Figure 13 As shown, in this embodiment, an alternative implementation is provided, specifically providing the following semiconductor light-emitting element, which includes a semiconductor light-emitting sequence, and the semiconductor light-emitting sequence includes a first conductivity type semiconductor layer 10, a light-emitting layer 9 and a second conductivity type semiconductor layer 8;

[0128] The electrical insulating layer 7 on the side of the second conductive type semiconductor layer 8 has multiple openings, and one side of the second conductive type semiconductor layer is set as an electrical contact area and an electrical insulating area.

[0129] The opening is filled with ohmic contact blocks 14, and there are many ohmic contact blocks 14, but they are not formed under the main pad electrode for injecting current outside the first electrode. The shape of the ohmic contact block 14 is block, and the metal material is at least one of gold germa...

Embodiment 3

[0149] Such as Figure 22 As shown, in this embodiment, another semiconductor light emitting element is provided, and the semiconductor light emitting sequence includes a first conductivity type semiconductor layer 10, a light emitting layer 9 and a second conductivity type semiconductor layer 8;

[0150] The side of the second conductivity type semiconductor layer 8 includes an electrical insulating layer, the fluoride electrical insulating layer has multiple openings, and one side of the second conductivity type semiconductor layer is set as an electrical contact area and an electrical insulation area.

[0151] The openings are filled with ohmic contact blocks or ohmic contact layers.

[0152] The electrical insulating layer is fluoride, specifically at least one of magnesium fluoride and calcium fluoride.

[0153] The fluorine ions of the fluoride diffuse into the second conductivity type semiconductor layer to form a current blocking region.

[0154] The first electrode ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com