A kind of anti-mold and mildew-removing agent for ceiling and preparation method thereof

A mildew remover and ceiling technology, applied in botany equipment and methods, biocides, bactericides, etc., can solve the problems of putty paint falling off, destroying the overall decoration, and decreasing aesthetics, so as to avoid sterilization treatment, improve air, The effect of reducing potency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: Preparation 1 of mildew and antifungal agent:

[0036] Adhesive granules in this example were weighed according to the following raw materials: 100g N-methylolacrylamide, 100g acrylic acid, 10g calcium chloride, 30g ammonium persulfate, 5g N, N-methylenebisacrylamide, 10g casein Sodium, 5g lactic acid, 2g polyvinyl alcohol.

[0037] The preparation method of the adhesive particle of the present embodiment is as follows:

[0038]Gel precursor preparation: Dissolve N-methylolacrylamide in 700ml of sodium hydroxide solution with a concentration of 2mol / L, mix well, add acrylic acid, 600ml deionized water and stir well, then add polyvinyl alcohol, pass Ammonium sulfate, N, N-methylenebisacrylamide, stir evenly, pass nitrogen into the solution, exhaust for 20 minutes, discharge the air in the solution and seal it, heat it in a water bath to 50°C, and stir for 1 hour to obtain a gel Precursor;

[0039] Gel modification: Add lactic acid, sodium caseinate, and ...

Embodiment 2

[0046] Embodiment 2: Preparation two of mildew and antifungal agent:

[0047] Adhesive granules in this example are weighed according to the following raw materials: 200g N-methylolacrylamide, 180g acrylic acid, 20g calcium chloride, 60g ammonium persulfate, 10g N, N-methylenebisacrylamide, 12g casein Sodium, 10g lactic acid, 3g polyvinyl alcohol.

[0048] The preparation method of the adhesive particle of the present embodiment is as follows:

[0049] Gel precursor preparation: Dissolve N-methylolacrylamide in 1200ml of sodium hydroxide solution with a concentration of 2mol / L, mix well, add acrylic acid, 700ml deionized water and stir well, then add polyvinyl alcohol, pass Ammonium sulfate, N, N-methylenebisacrylamide, stir evenly, pass nitrogen into the solution, exhaust for 20 minutes, discharge the air in the solution and seal it, heat it in a water bath to 50°C, and stir for 1 hour to obtain a gel Precursor;

[0050] Gel modification: Add lactic acid, sodium caseinate,...

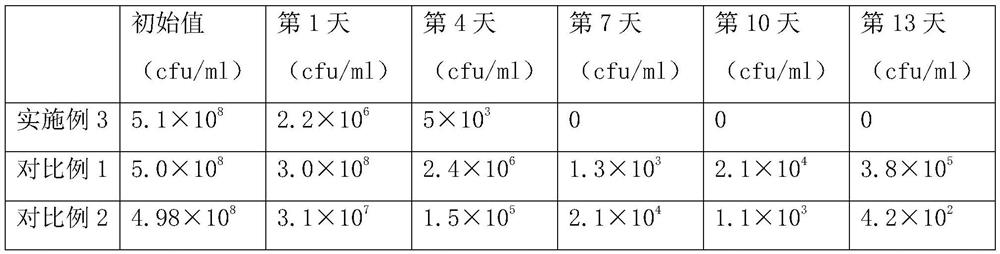

Embodiment 3

[0057] Embodiment 3: Preparation three of mildew and antifungal agent:

[0058] Adhesive granules in this example were weighed according to the following raw materials: 150g N-methylolacrylamide, 150g acrylic acid, 15g calcium chloride, 40g ammonium persulfate, 6g N, N-methylenebisacrylamide, 11g casein Sodium, 8g lactic acid, 2g polyvinyl alcohol.

[0059] The preparation method of the adhesive particle of the present embodiment is as follows:

[0060] Gel precursor preparation: Dissolve N-methylolacrylamide in 900ml of sodium hydroxide solution with a concentration of 2mol / L, mix well, add acrylic acid, 500ml deionized water and stir well, then add polyvinyl alcohol, pass Ammonium sulfate, N, N-methylenebisacrylamide, stir evenly, pass nitrogen into the solution, exhaust for 20 minutes, discharge the air in the solution and seal it, heat it in a water bath to 50°C, and stir for 1 hour to obtain a gel Precursor;

[0061] Gel modification: Add lactic acid, sodium caseinate,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com