Application of supported bifunctional catalyst in preparation of 3-acetylpropanol from furfural

A bifunctional catalyst and acetylpropanol technology, applied in the field of medicine and chemical industry, can solve the problems of expensive alkynes as raw materials, limited wide-range application, and low concentration of reaction substrates, and achieve cheap raw materials, high reactivity and selectivity , The effect of easy product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

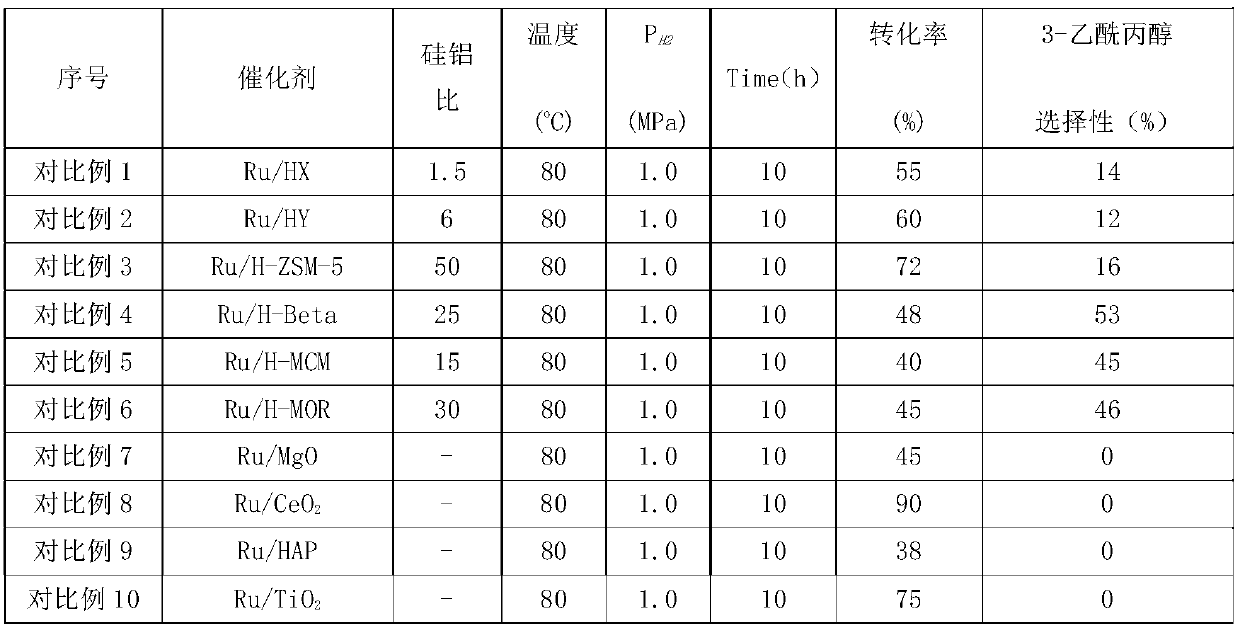

[0028] Add 0.1g furfural and 5g water into a 50ml autoclave. At the same time, add 50mg ammonium molecular sieve supported ruthenium bifunctional catalyst (2wt% of Ru mass loading) into the reactor, pass 1.0MPa hydrogen into it, and seal the Parr kettle. The autoclave was heated to 80°C for 25 minutes to react. After 10 hours of reaction, the reaction was stopped and cooled to room temperature. The liquid product and the catalyst were separated by centrifugation. The liquid product was analyzed by gas chromatography. The product yield is (number of moles of carbon in 3-acetylpropanol) / (total number of moles of carbon in the raw materials)×100%, and other products include furfuryl alcohol, cyclopentanone, cyclopentanol, 1,4-pentanediol, The yield was not calculated. The results of the reaction are shown in Table 2.

[0029]

[0030]

[0031] It can be concluded from Table 2 that in the reaction of furfural to prepare 3-levulinol, the catalytic activity and selectivity of ammonium...

Embodiment 4-7

[0033] 0.1g furfural and 5g water are added to a 50ml autoclave. At the same time, 50mg Ru / H-Beta-N catalyst (Ru mass loading is 2%) is added to the reactor, 0.5MPa hydrogen is introduced, and the Parr kettle is closed. The autoclave was heated to a certain temperature within minutes to react. After 10 hours of reaction, the reaction was stopped and cooled to room temperature. The liquid product and the catalyst were separated by centrifugation, and the liquid product was analyzed by gas chromatography. The reaction results are shown in Table 3 below.

[0034]

[0035] It can be concluded from Table 3 that with Ru / H-Beta-N as the catalyst, the reaction temperature is between 60-120°C, which is beneficial to the selective preparation of 3-acetylpropanol from furfural.

Embodiment 8-9

[0037] Add 0.1g furfural and 5g water into a 50ml autoclave. At the same time, add 50mg Ru / H-Beta-N catalyst (2% Ru mass loading) into the reactor, pass 0.5-3MPa hydrogen, and seal the Parr kettle. The autoclave was heated to 80°C for 25 minutes to react. After 10 hours of reaction, the reaction was stopped and cooled to room temperature. The liquid product and the catalyst were separated by centrifugation. The liquid product was analyzed by gas chromatography. The reaction results are shown in Table 4 below.

[0038]

[0039] It can be concluded from Table 4 that with Ru / H-Beta-N as the catalyst, furfural can obtain 3-acetylpropanol with high selectivity when the hydrogen pressure is 0.5-3.0MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com