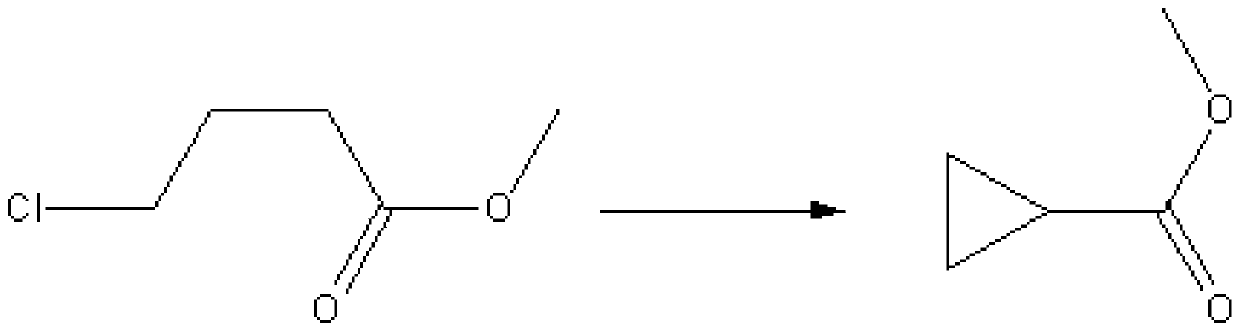

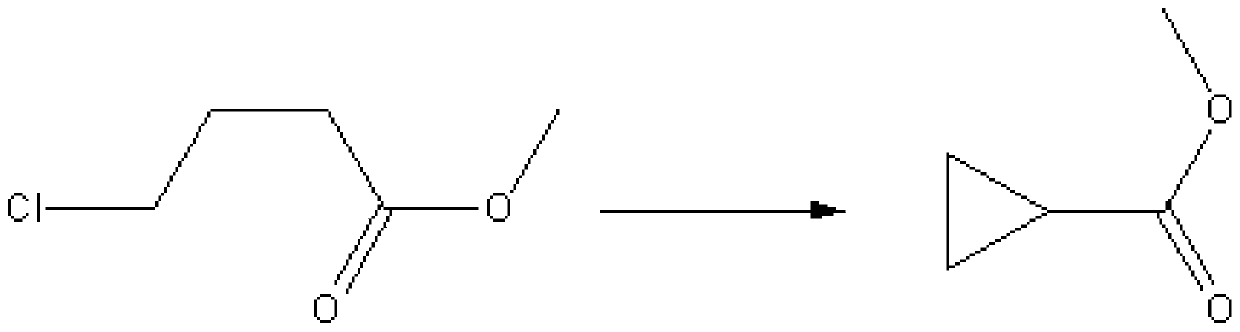

Method for synthesizing methyl cyclopropanecarboxylate

A technology for the synthesis of methyl cyclopropanecarboxylate, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds. And the effect of low use, low risk and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A method for synthesizing methyl cyclopropanate, adding 800-1200g of potassium carbonate to a clean 1800-2200ml reaction bottle, then adding 800-900g of xylene, and adding methyl chlorobutyrate 740 dropwise at a temperature of 85-100°C -920g, after dripping, control the temperature at 85-100°C for 1-5h, cool down to 30-50°C at the end of the heat preservation, filter, wash the filter cake with xylene, combine the filtrate, and rectify the filtrate to obtain methyl cyclopropanate 522 -602g, the yield is 90-98%, and xylene is recovered and applied mechanically.

Embodiment 2

[0018] In the synthetic method of methyl cyclopropanate described in Example 1, 1000 g of potassium carbonate was added in a clean 2000 ml reaction bottle, and then 860 g of xylene was added, and 780 g of methyl chlorobutyrate was added dropwise at a temperature of 85 to 100° C. After completion, control the temperature at 85-100°C for 3 hours, cool down to below 40°C at the end of the heat preservation, filter, wash the filter cake with xylene, combine the filtrate, and rectify the filtrate to obtain 562g of methyl cyclopropanate, with a yield of 95%. Recycling.

Embodiment 3

[0020] Synthetic method of methyl cyclopropanate described in embodiment 1, in clean 1800ml reaction bottle, add salt of wormwood 800g, then add dimethylbenzene 800g, control temperature and drop methyl chlorobutyrate 740g at 85 ℃, dripping finishes, Control the temperature at 85°C for 1 hour, cool down to below 30°C at the end of the heat preservation, filter, wash the filter cake with xylene, combine the filtrate, and rectify the filtrate to obtain 522g of methyl cyclopropanate, with a yield of 90%. The xylene is recovered and used mechanically.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com