Epoxidized camellia oil monomer, monomer-based polymer, pressure-sensitive adhesive, and preparation method thereof

A technology of epoxy tea and pressure-sensitive adhesives, applied in the direction of ester copolymer adhesives, adhesive types, organic chemistry, etc., can solve the problems of many equipment, long production process, serious corrosion, etc., and achieve good cohesion, good Adhesive performance, the effect of realizing high-value utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

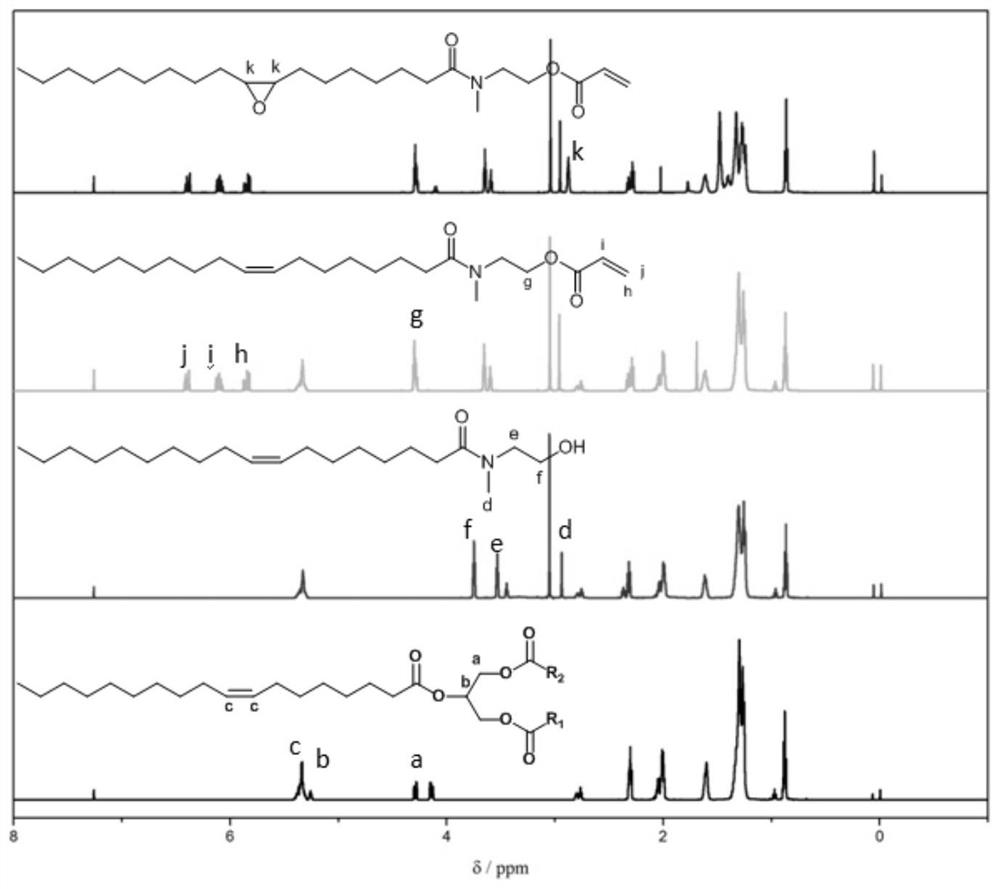

[0070] The preparation method of epoxy camellia oil monomer

[0071] (1) Preparation of camellia oil precursor: Pour 100g camellia seed oil into a round bottom flask, pass nitrogen protection at 100°C for 1h, then cool down to 60°C, add 33.2g 2-methylaminoethanol and 1.5mL Sodium methoxide, react for 4 hours, add 400mL dichloromethane to dissolve the reaction mixture, pour the reaction solution into a separatory funnel, then add saturated saline, separate the layers to take the dichloromethane layer, add anhydrous magnesium sulfate to the obtained solution to dry and remove water, and then filtered to remove anhydrous magnesium sulfate, and the obtained mixed solution was removed by vacuum rotary evaporation to remove methylene chloride to obtain a camellia oil precursor;

[0072] (2) Preparation of camellia oil monomer: Dissolve 94g of camellia oil precursor and 39mL of triethylamine in parts by weight in 120mL of dichloromethane, add 22.9mL of acryloyl chloride dropwise unde...

Embodiment 3

[0081] The preparation method of epoxy camellia oil monomer

[0082] (1) Preparation of camellia oil precursor: Pour 80g of camellia seed oil into a round-bottomed flask, pass nitrogen protection at 100°C for 1h, then cool down to 60°C, add 26g of 2-methylaminoethanol and 1.2mL of methanol Sodium, react for 4 hours, add 400mL dichloromethane to dissolve the reaction mixture, pour the reaction solution into a separatory funnel, then add saturated saline, separate the layers to take the dichloromethane layer, add anhydrous magnesium sulfate to the obtained solution to dry and remove water , and then filtered to remove anhydrous magnesium sulfate, and the obtained mixed solution was removed by vacuum rotary evaporation to remove methylene chloride to obtain a camellia oil precursor;

[0083] (2) Preparation of camellia oil monomer: Dissolve 60g of camellia oil precursor and 27mL of triethylamine in 120mL of dichloromethane, add 16mL of acryloyl chloride dropwise in an ice-water b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com