Chitin deacetylase

A deacetylase and chitin technology, applied in the field of protease, can solve the problems of insignificant increase in enzyme activity of genetically engineered bacteria, narrow substrate spectrum, and low enzyme production activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1 Substrate Spectrum

[0022] The substrate spectrum of RCDA was studied, and large molecular chitin powder, colloidal chitin, ethylene glycol chitin, chitosan with a deacetylation degree of 85%, and chitooligosaccharides with small molecular weight and bands were selected. Several amino acids of the acetyl group were used as substrates, and 5 mL of RCDA crude enzyme solution was added to the excess substrate solution. Under stirring, the mixture was allowed to react at 37°C and pH 4.0, and stirred for 12 hours. Then the sample was boiled for 5 minutes, and the deacetylation ability of its different substrates was characterized by the content of acetic acid generated by deacetylation by high performance liquid chromatography, and the substrate activity (157.6U / mL) of 4-nitroacetanilide was set is 100%. The results are shown in Table 1. RCDA has activity on most of the tested substrates, including low molecular weight chitosan oligosaccharides, colloidal chitin,...

Embodiment 2

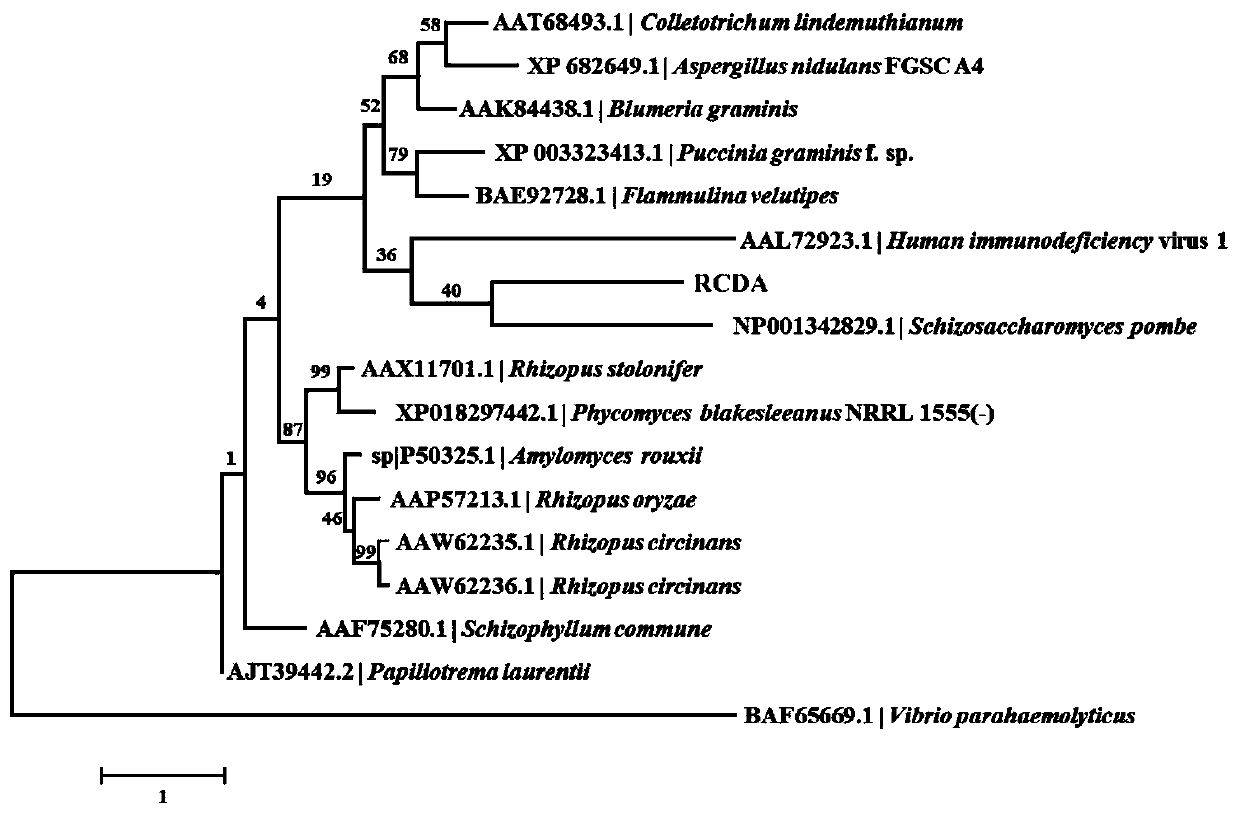

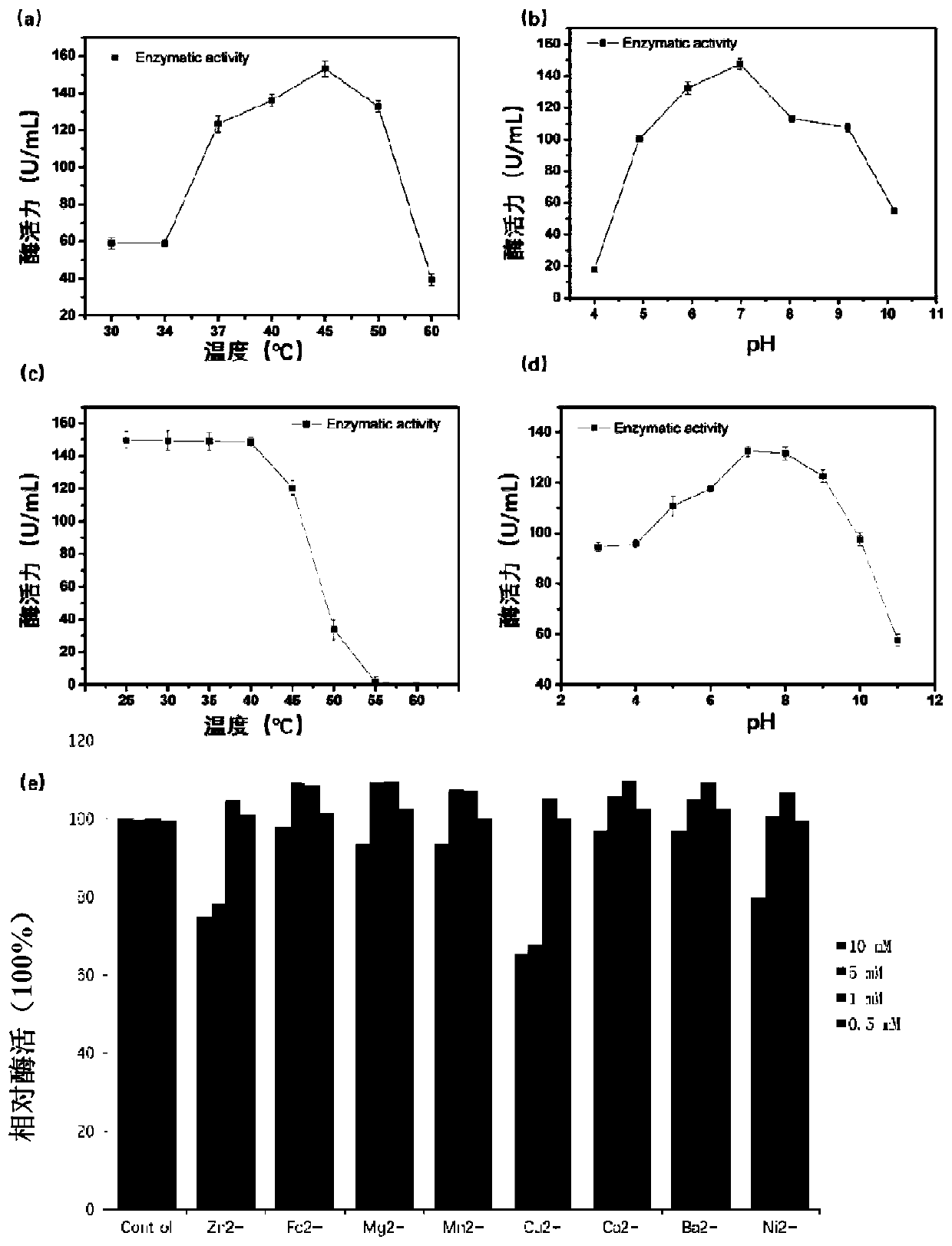

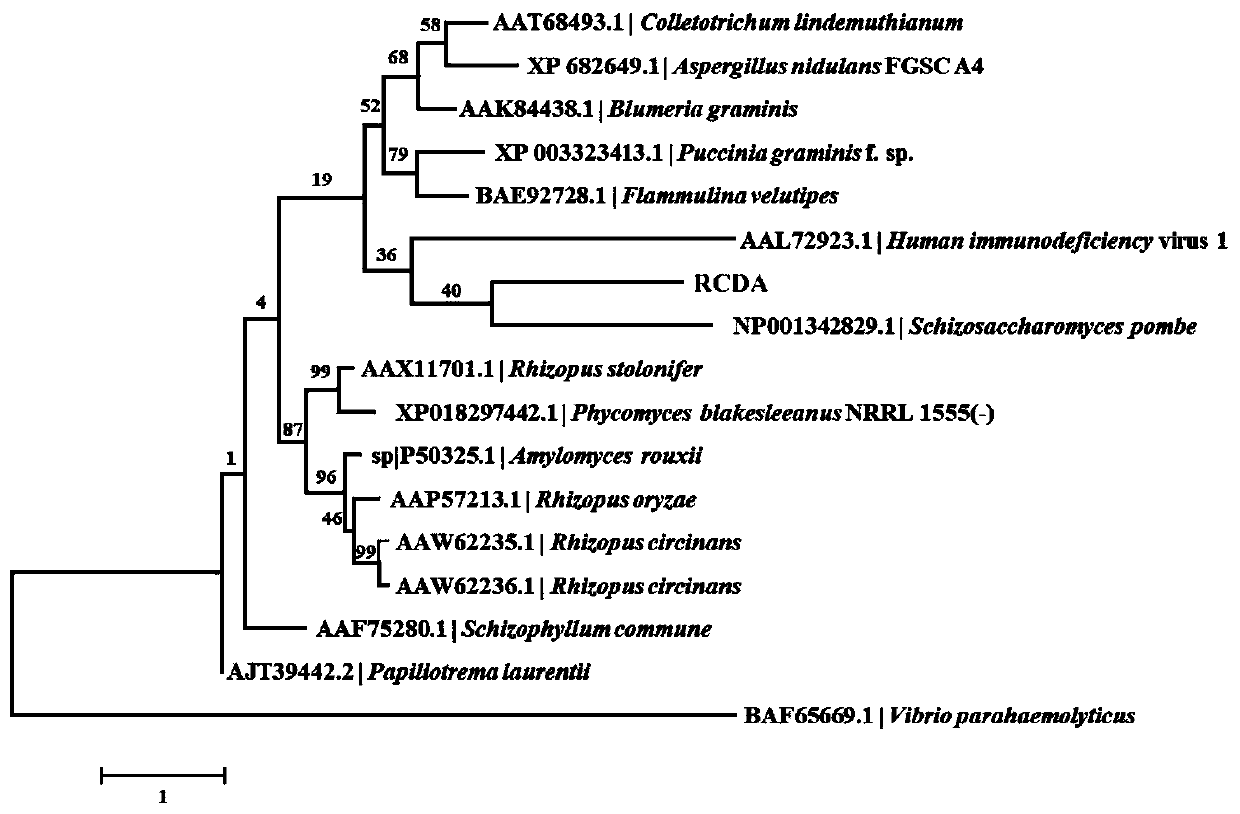

[0026] Embodiment 2 enzymatic properties

[0027] (1) In order to determine the optimal reaction temperature of the enzyme, the enzyme was reacted at different temperatures (30-60°C) and pH 7.0 for 60 minutes to detect the enzyme activity;

[0028] (2) In order to study the temperature stability of the enzyme, the enzyme was pre-incubated at different temperatures (25-60°C) for 30 minutes, pH 7.0, and reacted at 37 degrees for 60 minutes to detect the remaining enzyme activity of the enzyme;

[0029] (3) In order to determine the optimal pH value, the enzyme activity of the enzyme was measured for 60 minutes at 37°C under different pH conditions;

[0030] (4) In order to study the pH value stability of the enzyme, the enzyme was placed in various pH2-10 buffers for pre-incubation overnight, and then reacted at pH7.0, 37 degrees for 60 minutes to detect the remaining enzyme activity;

[0031] (5) Simultaneously studied RCDA and different metal ions Zn 2+ , Fe 2+ , Mg 2+ , M...

Embodiment 3

[0042] Embodiment 3 Application of RCDA

[0043]Chitin powder was first pretreated with 48% choline aqueous solution at 90°C for 12 hours, the amount of choline added was 10mL per 5g of material, filtered after pretreatment and the ionic liquid remaining in the solid phase was washed with deionized water to pH6 .8-7.0, then dry at 105°C to constant weight. Weigh 1 g of the dried material and add 10 mL of the chitin deacetylase crude enzyme solution of the present invention (enzyme activity is 157.6 U / mL) to react at 37°C for 12 hours, and use liquid chromatography to detect the total amount of acetic acid generated in the liquid after the deacetylation reaction. The amount reaches 127mg / g chitin powder.

[0044] In this example, the role of choline is to destroy the crystal structure of chitin and increase the area of action of the enzyme. After pretreatment, it is the pretreated chitin powder that is dried to constant weight. The addition of RCDA produced The deacetylatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com