Recombinant escherichia coli KLUGIN73 and application thereof

A technology for recombining Escherichia coli and Escherichia coli, which is applied in the direction of recombinant DNA technology, applications, bacteria, etc., to achieve the effects of cost reduction, simple and single reaction conditions, and wide substrate spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

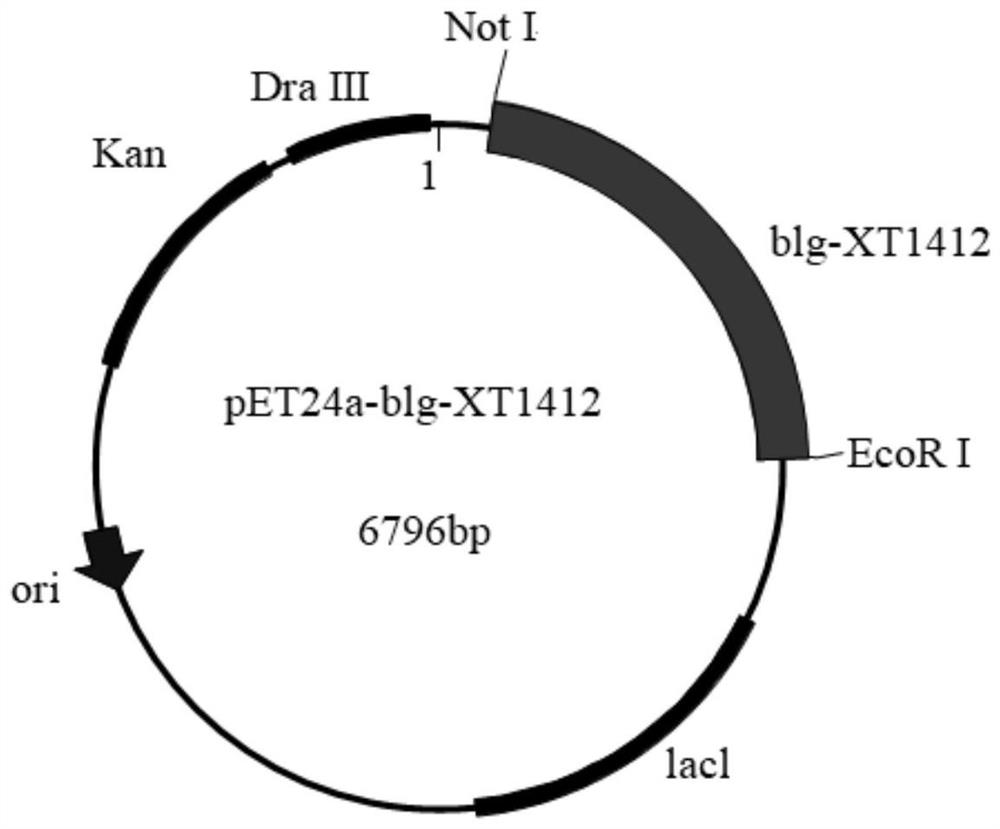

[0055] The construction of embodiment 1 recombinant escherichia coli KLUGIN73

[0056] 1. Cloning of blg-XT1412 enzyme gene

[0057] 1.1 Primer design

[0058] According to the blg-XT1412 gene sequence, degenerate primers were designed online using GeneFisher software:

[0059] Upstream primer: 5'-ttaGCGGCCGCATGTCCCCCATCCTC-3';

[0060] Downstream primer: 5'-ggcGAATTCTTAGTGATGGTGATG-3'.

[0061] 1.2 Template preparation

[0062] With the liquid YPD medium of 100ml, activate Kluyveromyces lactis (Kluyveromyces lactis) XT1412 (Kluyveromyces lactis (Kluyveromyces lactis) XT1412 is disclosed in publication number and is CN10812936A, and the title of invention is " Kluyveromyces lactis mutant strain and its Glycosidase and application" Chinese invention patent), 28 ℃, 250rpm continuous culture for 2 days. After the cultivation, centrifuge at 5000rpm for 10min, collect the bacterial cells to extract genomic DNA, and store the product at -20°C until use.

[0063] 1.3 Gene ampli...

Embodiment 2

[0082] The production and fermentation process of embodiment 2 recombinant escherichia coli KLUGIN73

[0083] 2.1 Determination of fermentation medium The fermentation medium is composed of carbon source, nitrogen source and inorganic salts, suitable for 5-10000L fermenter, and the specific components are as follows:

[0084] Carbon source: glycerol 1-3%;

[0085] Nitrogen source: yeast extract powder 0.2-1.5%, tryptone 1-3%; inorganic salt: potassium dihydrogen phosphate 0.1-0.4%, dipotassium hydrogen phosphate 0.1-0.3%, ammonium sulfate 0.05-0.2%, pH: 6- 8 (ammonia adjustment).

[0086] 2.2 Determination of fermentation culture and induction enzyme production conditions

[0087] The fermentation medium is shown in 2.1, and the fermentation conditions are as follows:

[0088] Inoculation amount: 0.1-2% (volume ratio);

[0089] Culture time: 12-24 hours;

[0090] Cultivation temperature: 25-40°C

[0091] Stirring speed: 100-250r / min

[0092] After the cultivation, IPTG ...

Embodiment 3

[0098] Embodiment 3 recombinant escherichia coli KLUGIN73 produces the method for glycosidase

[0099] 1) Activating the recombinant Escherichia coli KLUGIN73,

[0100] 2) Place activated recombinant Escherichia coli KLUGIN73 in a fermentation medium for fermentation to obtain a fermentation product; wherein, the formulation of the fermentation medium is:

[0101] Carbon source: glycerin 1-3%; nitrogen source: yeast extract powder 0.2-1.5%, tryptone 1-3%; inorganic salts: potassium dihydrogen phosphate 0.1-0.4%, dipotassium hydrogen phosphate 0.1-0.3%, ammonium sulfate 0.05-0.2%; pH: 6-8 (adjusted by ammonia water);

[0102] Fermentation conditions: inoculum size: 0.1-2% (volume ratio); culture time: 12-24 hours; culture temperature: 25-40°C; stirring speed: 100-250r / min;

[0103] 3) Inducing enzyme production on the fermentation product to obtain Escherichia coli KLUGIN73 containing the recombinant protein XT1412; wherein,

[0104] Enzyme production conditions: add IPTG (i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com