Flexible electrogenerated variable emissivity device and preparation method thereof

A technology of emissivity and flexible electricity, applied in instruments, protective equipment, offensive equipment, etc., can solve the problems of limited infrared modulation ability and difficulty in achieving flexibility, and achieve the effect of improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The present invention also proposes a method for preparing a flexible electrovariable emissivity device, comprising the following steps:

[0055] S1: modifying the surface of the flexible polymer film and / or plating a transition layer on one side of the film;

[0056] S2: Depositing a metal film on one side of the surface-modified flexible polymer film to obtain a working electrode;

[0057] or,

[0058] Depositing a metal film on the transition layer side of the flexible polymer film or the surface-modified flexible polymer film to obtain a working electrode;

[0059] S3: preparing a gel electrolyte, and soaking the porous diaphragm with the gel electrolyte to obtain a gel electrolyte layer;

[0060] S4: directly depositing a conductive layer on one side of the substrate to obtain a counter electrode;

[0061] S5: The side of the working electrode obtained in S2 deposited with a metal thin film is stacked with the side of the gel electrolyte layer obtained in S3, an...

Embodiment 1

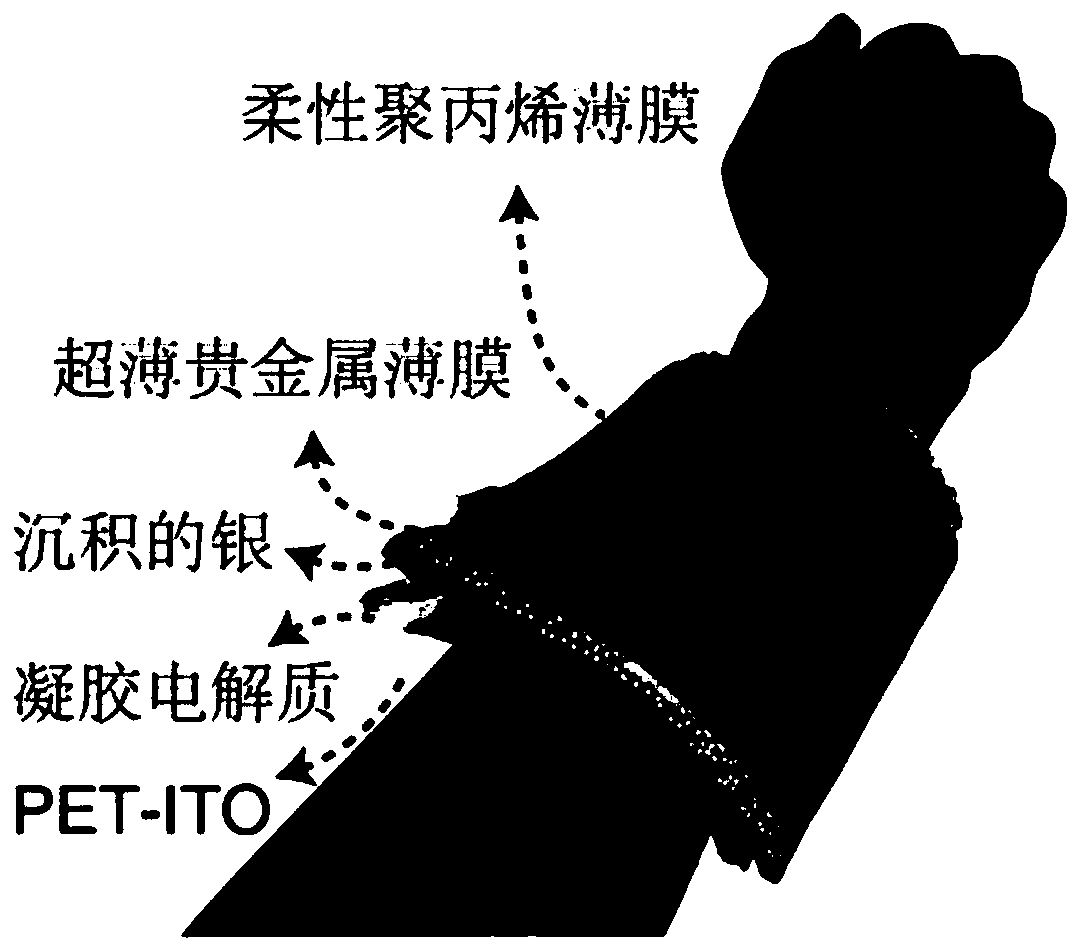

[0077] This embodiment proposes a flexible electrovariable emissivity device, such as figure 1 As shown, including working electrode, gel electrolyte layer and counter electrode from top to bottom;

[0078] The working electrode comprises a polypropylene film and a metal film, the polypropylene film is a surface-modified film, and the metal film is deposited on the surface-modified film;

[0079] The electrolyte layer includes a porous membrane and an electrolyte, and the electrolyte is infiltrated in the porous membrane; the electrolyte includes an electrochromic material containing metal ions and a solvent, and the metal ions are metals capable of reversible electrodeposition and dissolution ions and the metal of the metal ion is different from the metal used for the metal thin film.

[0080] In this embodiment, the modified polypropylene film is a polypropylene film with oxygen-containing functional groups introduced on the surface, with a thickness of 30 μm; the metal fil...

Embodiment 2

[0096] This embodiment proposes a flexible electrovariable emissivity device, which sequentially includes a working electrode, a gel electrolyte layer, and a counter electrode from top to bottom;

[0097] The working electrode comprises a polyester film and a metal film, one side of the polyester film is plated with a transition layer, and the metal film is deposited on the transition layer;

[0098] The electrolyte layer includes a porous membrane and an electrolyte, and the electrolyte is infiltrated in the porous membrane; the electrolyte includes an electrochromic material containing metal ions and a solvent, and the metal ions are metals capable of reversible electrodeposition and dissolution ions and the metal of the metal ion is different from the metal used for the metal thin film.

[0099] In the present embodiment, the thickness of the polyester film is 5 μm; the metal film is a ruthenium (Ru) film with a thickness of 2 nm; the gel electrolyte in the gel electrolyte ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com