A kind of preparation method of 4,4-biphenyl ether dianhydride

A technology of biphenyl ether dianhydride and dimethylformamide, which is applied in the field of preparation of 4,4-biphenyl ether dianhydride, can solve the problems of complex preparation methods, many by-products, and low yield, and achieve the production cost Low, less by-products, high reaction yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of 4,4-biphenyl ether dianhydride, mixing compound I, compound II, N,N-dimethylformamide and toluene at a molar ratio of 1:1:0.5:0.5, and proceeding at 110°C After reacting for 6 hours, the reaction solution was cooled to 80°C at a cooling rate of 6°C / h, filtered to remove solid matter, and then cooled to 20°C at a cooling rate of 6°C / h, filtered to obtain 4,4-biphenyl ether di anhydride crystals.

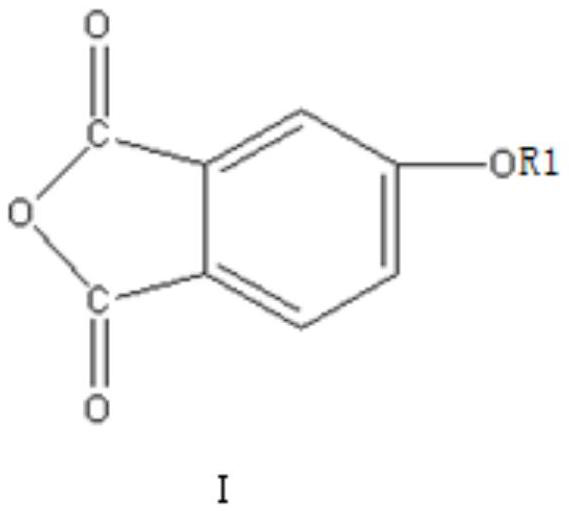

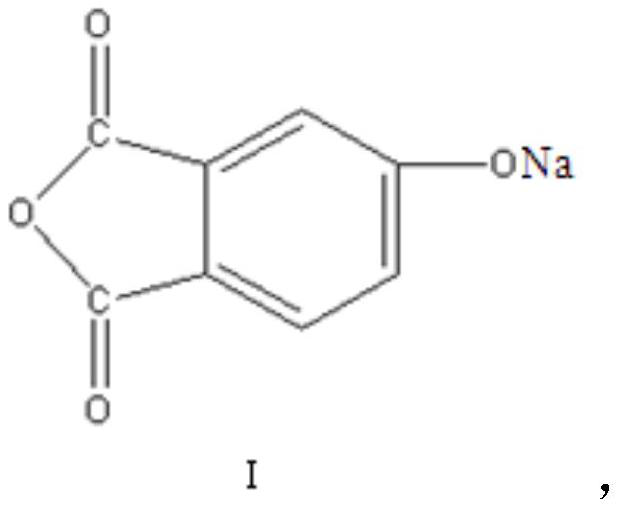

[0036] Wherein the structural formula of compound I is:

[0037]

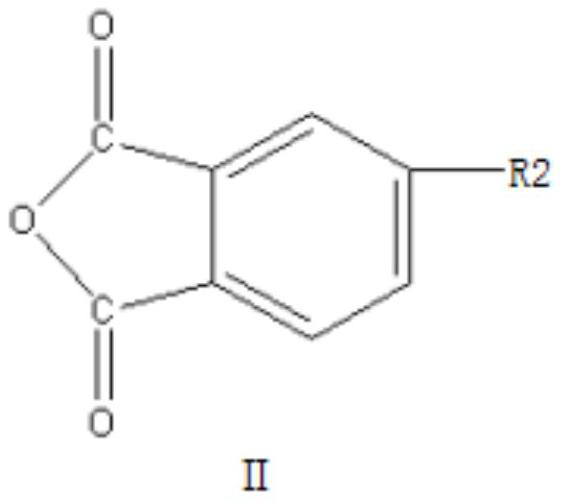

[0038] The structural formula of compound II is:

[0039]

[0040] The yield and purity of the obtained 4,4-biphenyl ether dianhydride were detected, and the yield was 98.1%, and the purity was 98%.

Embodiment 2

[0042] A preparation method of 4,4-biphenyl ether dianhydride, mixing compound I, compound II, N,N-dimethylformamide and toluene at a molar ratio of 1:1:0.5:0.5, and proceeding at 110°C After reacting for 6 hours, the reaction solution was cooled to 80°C at a cooling rate of 6°C / h, filtered to remove solid matter, and then cooled to 20°C at a cooling rate of 6°C / h, filtered to obtain 4,4-biphenyl ether di Anhydride crystals; then dissolve 4,4-biphenyl ether dianhydride crystals in N,N-dimethylformamide (water content less than 500ppm), so that 4,4-biphenyl ether dianhydride and N,N-di The molar ratio of methyl formamide is 1:1, heat up to 80°C, filter to remove solid matter, cool the filtrate to 20°C at a cooling rate of 6°C / h, filter, and dry the filtered crystals at 160°C for 7 hours , to obtain 4,4-biphenyl ether dianhydride.

[0043] Wherein the structural formula of compound I is:

[0044]

[0045] The structural formula of compound II is:

[0046]

[0047] The y...

Embodiment 3

[0049] A method for preparing 4,4-biphenyl ether dianhydride, mixing compound I, compound II, dimethyl sulfoxide and xylene in a molar ratio of 1:1.1:2:1, and reacting at 120°C for 8 hours, The reaction solution was cooled to 90°C at a cooling rate of 7°C / h, filtered to remove solid matter, then cooled to 22°C at a cooling rate of 7°C / h, and filtered to obtain 4,4-biphenyl ether dianhydride crystals; Dissolve 4,4-biphenyl ether dianhydride crystals in N,N-dimethylacetamide (water content less than 500ppm), make 4,4-biphenyl ether dianhydride and N,N-dimethylacetamide The molar ratio is 1:2, heated to 90°C, filtered to remove solid matter, the filtrate was cooled to 22°C at a cooling rate of 7°C / h, filtered, and the filtered crystals were dried at 170°C for 6h to obtain 4, 4-Diphenyl ether dianhydride.

[0050] Wherein the structural formula of compound I is:

[0051]

[0052] The structural formula of compound II is:

[0053]

[0054] The yield and purity of the obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com