Collagen-sodium humate compound suitable for hemostatic material and preparation method thereof

A technology of sodium humate and hemostatic material, which is used in drug delivery, pharmaceutical formulations, bandages, etc., can solve the problems of chitosan having no biological activity, high price of alginic acid dressing, and no self-adhesiveness, etc., to improve stability. and mechanical properties, improve hemostatic properties, high value-added effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention discloses a preparation method of a collagen-sodium humate compound suitable for hemostatic materials, which specifically includes the following steps:

[0031] (1) Take 1-10 parts of collagen sponge and dissolve it in saline solution to prepare a collagen solution with a concentration of 0.1%-1.5%; the salt content in the saline solution is controlled at 80-200mmol / L; the temperature is controlled below 10 °C;

[0032] (2) Take 0.25 to 40 parts of sodium humate and dissolve it in a salt solution at room temperature to prepare a sodium humate solution with a concentration of 0.025% to 6%; the salt content in the salt solution is controlled at 80 to 200mmol / L;

[0033] (3) Slowly add 0.025% ~ 6% sodium humate solution dropwise to the stirring collagen solution, the ratio of sodium humate to collagen dry weight is 1:0.05 ~ 20; the temperature is controlled below 10 °C, and the pH value is controlled At 4~9, stir for 6~24h to prepare the collagen-sodium humat...

Embodiment 1

[0039] Take 1 part of collagen sponge, dissolve it in 100 parts of 120mmol / L sodium chloride solution at 4°C to prepare a collagen solution with a concentration of 1%, and adjust the pH to 7.0 with sodium hydroxide. Get 1 part of sodium humate, dissolve it in 100 parts of 120mmol / L sodium chloride solution at normal temperature to prepare a sodium humate solution with a concentration of 1%, adjust the pH to 7.0 with sodium hydroxide; The sodium solution was slowly added dropwise to the stirring collagen solution, the ratio of sodium humate to collagen dry weight was 1:1, and the collagen-sodium humate composite solution was obtained by stirring for 12 hours; subsequently, the composite solution was placed at 37°C for self- Assembly to prepare composite hydrogels.

[0040] figure 1 It is the electrophoretic pattern of the collagen-sodium humate composite material in Example 1. Among them, the electrophoretic bands of collagen and collagen-sodium humate composite materials are...

Embodiment 2

[0042] Take 1 part of collagen sponge and dissolve it in 125 parts containing 10mmol / L disodium hydrogen phosphate / sodium dihydrogen phosphate and 100mmol / L sodium chloride at 10°C to prepare a 1% collagen solution with a pH value of about 7.4. Take 1.5 parts of sodium humate and dissolve it in a solution containing 10mmol / L disodium hydrogen phosphate / sodium dihydrogen phosphate and 100mmol / L sodium chloride at room temperature to prepare a 1.5% sodium humate solution with a pH value of about 7.4 ; Slowly add sodium humate solution dropwise to the stirring collagen solution at 10°C, the ratio of sodium humate to collagen dry weight is 6:4, and stir for 20 hours to obtain a collagen-sodium humate composite solution; subsequently, compound The solution was placed at 35°C for self-assembly to prepare composite hydrogels.

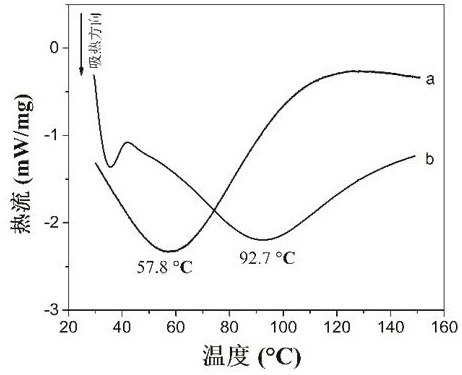

[0043] figure 2 It is the thermal stability test result of the collagen-sodium humate composite material in Example 2, which shows that the thermal stability...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com