Preparation method of heat-resistant polyurethane elastomer

A technology of polyurethane elastomers and polyurethane prepolymers, which is applied in the field of preparation of heat-resistant polyurethane elastomers, can solve the problems of poor dispersion of inorganic fillers and weakened mechanical properties of polyurethane elastomers, and achieve enhanced heat resistance, The effect of short reaction time and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

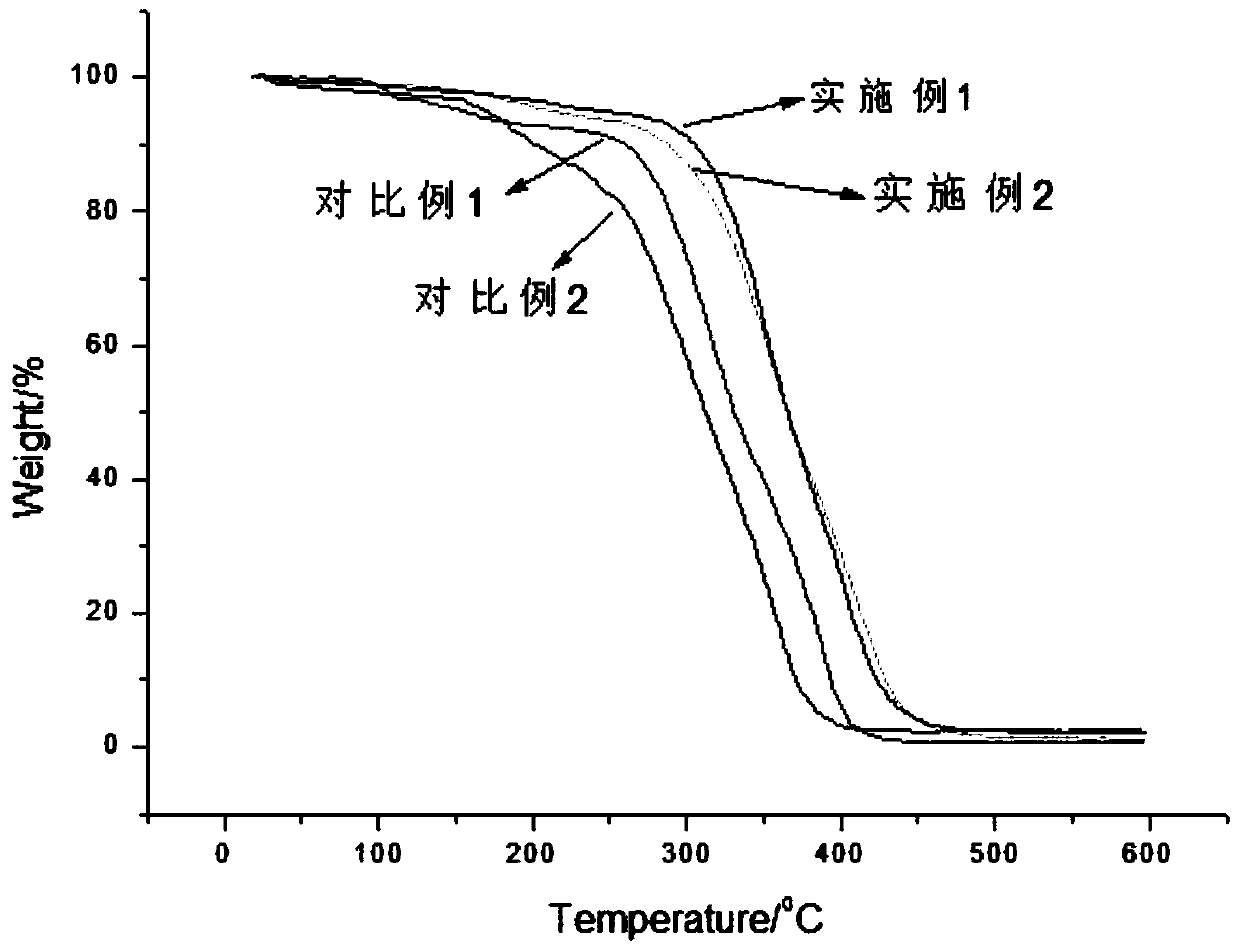

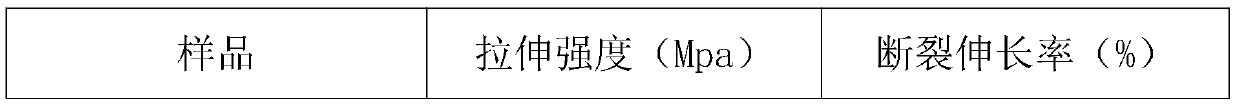

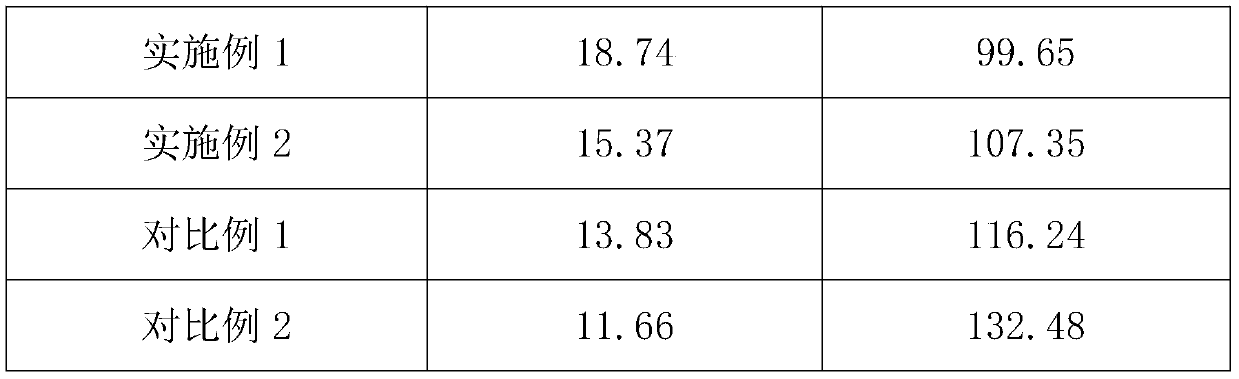

[0035] A preparation method of heat-resistant polyurethane elastomer, comprising the following steps:

[0036] 1) Mix 500g of polyoxypropylene triol with a molecular weight of 5000g / moL and 500g of polyoxypropylene diol with a molecular weight of 2500g / moL and vacuum dehydrate at 90°C to form component A, in which polyoxypropylene triol and polyoxypropylene diol The mass ratio of TDI and A component is kept at 80°C for 2 hours to obtain a polyurethane prepolymer, and the molar ratio of A component to TDI is 0.8:1;

[0037] 2) 300g of polyoxypropylene triol with a molecular weight of 5000g / moL is mixed with 45g of diatomite powder, and dry-milled with a ball mill to obtain a polyoxypropylene triol / diatomite compound;

[0038] 3) 50g of silicon carbide powder is dried after coarsening and activation treatment, and then subjected to electroplating treatment, wherein the electroplating solution is a mixed solution of nickel chloride and chromium chloride, and the mass-volume ratio...

Embodiment 2

[0041]A preparation method of heat-resistant polyurethane elastomer, comprising the following steps:

[0042] 1) Mix 500g of polyoxypropylene triol with a molecular weight of 5000g / moL and 500g of polyoxypropylene diol with a molecular weight of 2500g / moL and vacuum dehydrate at 100°C to form component A, in which polyoxypropylene triol and polyoxypropylene diol The mass ratio of 1.5:1; IPDI and A component were incubated at a temperature of 90°C for 1 hour to obtain a polyurethane prepolymer, and the molar ratio of A component to IPDI was 0.5:1;

[0043] 2) Mix 300 g of polyoxypropylene triol with a molecular weight of 5000 g / moL and 30 g of diatomite powder, and dry ball mill with a ball mill to obtain a polyoxypropylene triol / diatomite compound;

[0044] 3) 50g of silicon carbide powder is dried after coarsening and activation treatment, and then subjected to electroplating treatment, wherein the electroplating solution is a mixed solution of nickel chloride and chromium ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com