Preparation method for coating negative electrode material with vapor deposition carbon nanotube

A technology of carbon nanotubes and vapor deposition, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of poor cycle stability, complicated preparation methods, and low conductivity, and achieve the solution of silicon The effect of poor conductivity, simple preparation method, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Preparation Method of Coating Silicon Negative Electrode Material with Vapor-Deposited Carbon Nanotubes

[0030] This embodiment is a method for preparing a silicon negative electrode material coated with vapor-deposited carbon nanotubes, including the following steps in sequence:

[0031] Catalyst preparation: take the raw materials for the catalyst, prepare a catalyst solution, and sinter the catalyst solution at 650°C to obtain a catalyst powder;

[0032] Mixing: Put 1000g of silicon powder with a particle size of 100nm and 1g of catalyst into a VC mixer at 1500r / min and mix for 60min, then take it out;

[0033] Reduction: Put the mixed powder into the fluidized bed and pass H 2 Restore the powder, the flow rate is 1L / min and the reduction is 20min;

[0034] Fluidization: continue to reduce the powder obtained by using N in the fluidized bed 2 Fluidize with the flow rate of 400L / min, feed carbon source gas with the flow rate of 200L / min, in the present e...

Embodiment 2~5

[0038] Embodiments 2-5 Preparation method of coating silicon negative electrode material with vapor-deposited carbon nanotubes

[0039] Embodiments 2 to 5 are a method for preparing a silicon negative electrode material coated with vapor-deposited carbon nanotubes. The preparation process is the same as that of Example 1. The difference lies in the parameters during the preparation process. For details, see Table 1 below:

[0040] Table 1 Parameters in the preparation process

[0041] .

[0042] Wherein, the raw material component that makes catalyst is all the same as embodiment 1, and difference is that the consumption of each component is different, and concrete proportioning sees table 2:

[0043] Table 2 makes the content of each component in the raw material of catalyst

[0044] .

[0045] Wherein, the selection of the transition metal material is different from that in Example 1, and the components of the carrier material are the same as those in Example 6. The d...

Embodiment 6

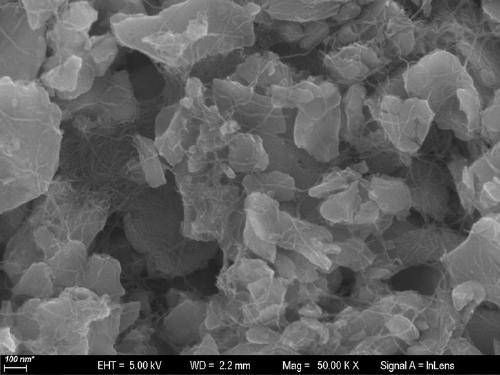

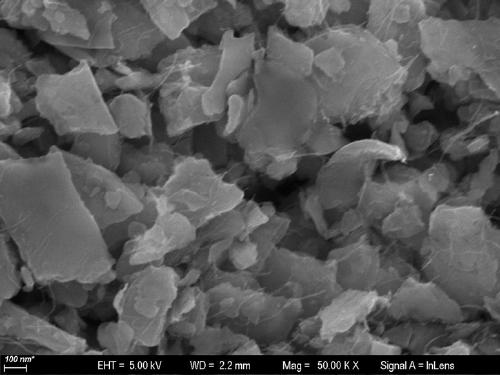

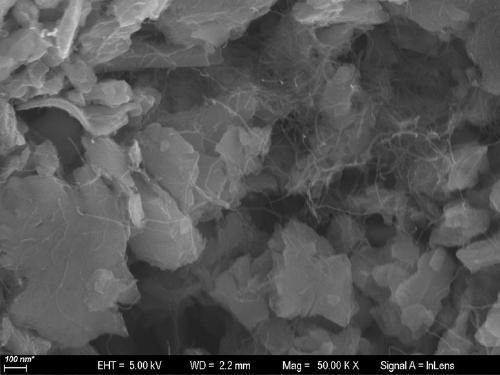

[0048] Example 6 Microstructure of silicon anode material coated with vapor-deposited carbon nanotubes

[0049] In order to observe the structure of the vapor-deposited carbon nanotube tube-coated silicon negative electrode material prepared by the present invention, the materials prepared in Examples 1 to 3 were imaged under a scanning electron microscope, as shown in Figure 1~3 Shown is the SEM (scanning electron microscope) image of the material. According to the pictures, it can be seen that carbon nanotubes are deposited in silicon powder, so that they are coated on the surface of silicon particles to form a conductive network; therefore, the conductivity of silicon powder can be improved by using the method of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com