Medical degradable magnesium-zinc-magnesium composite bar with osteoinductive activity, and preparation method thereof

A composite rod, osteoinductive technology, applied in pharmaceutical formulations, medical science, manufacturing tools, etc., can solve the problems of rapid degradation of implanted magnesium alloys, loss of osteoinductive activity, poor adhesion, etc., and achieves obvious osteoinductive activity. The effect of obvious biocompatibility and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

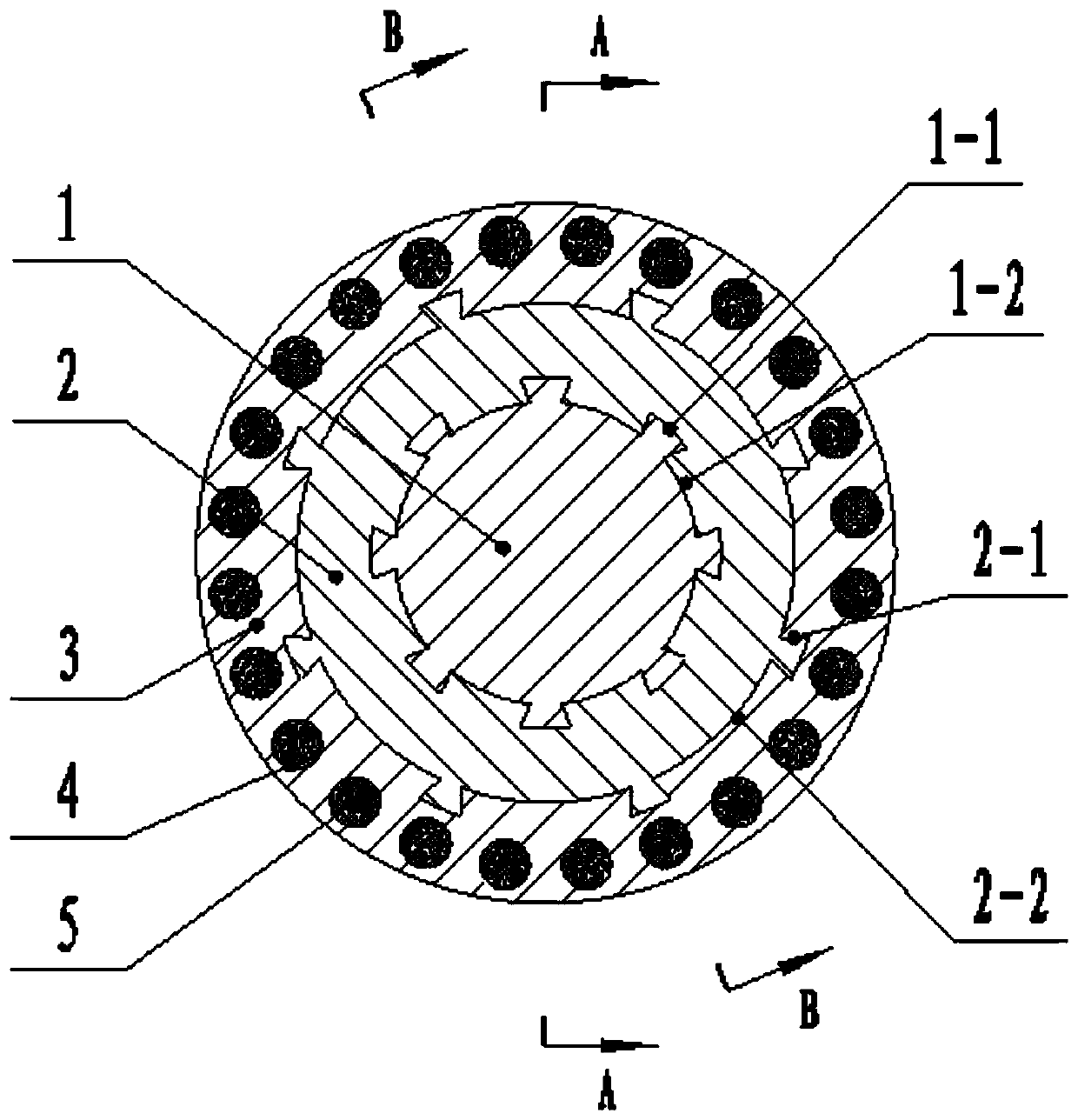

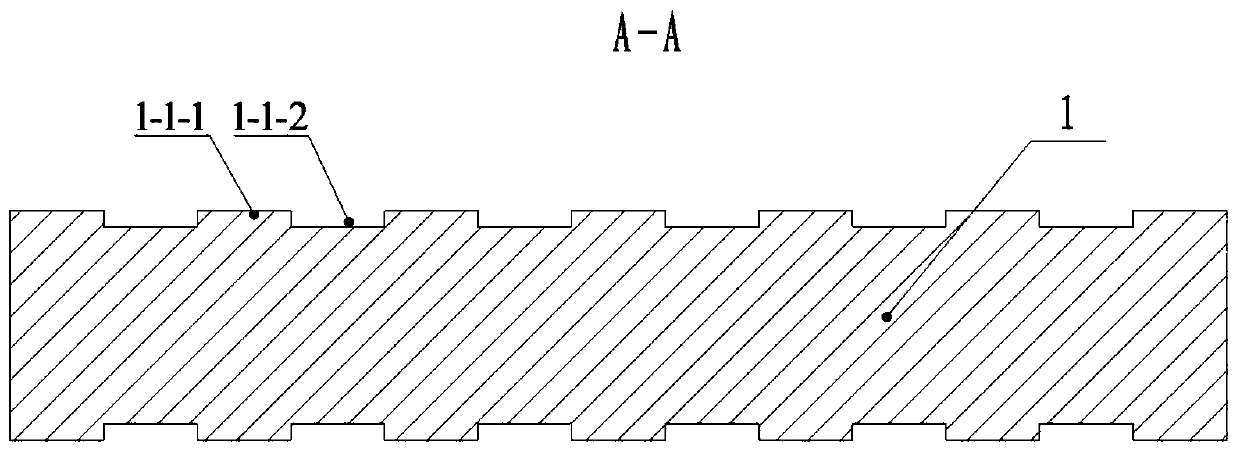

[0034] Such as Figures 1 to 3 Shown: a medical degradable magnesium-zinc-magnesium composite rod with osteoinductive activity, the innermost layer of the composite rod is deformed magnesium alloy layer 1, the middle layer is zinc alloy layer 2, and the outermost layer is cast magnesium The alloy layer 3, the deformed magnesium alloy layer 1 is provided with dovetail ribs I1-1 and dovetail grooves I1-2 combined with the zinc alloy layer, and the dovetail ribs I1-1 and dovetail grooves I1-2 are formed on the deformed magnesium alloy layer The circumferential direction of 1 is evenly spaced, and the dovetail rib I1-1 is provided with protrusions I1-1-1 and grooves I1-1-2 at intervals along the length direction of the bar, and the dovetail groove I1-2 runs through the length direction of the bar ;

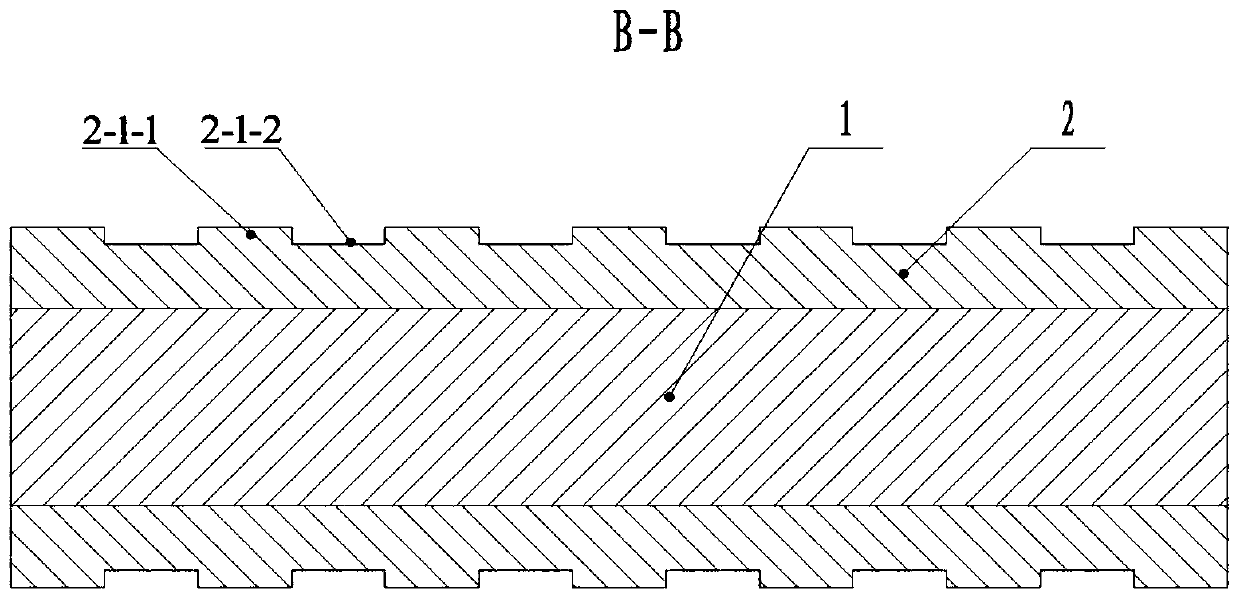

[0035] The zinc alloy layer 2 is provided with dovetail ribs II 2-1 and dovetail grooves II 2-2 combined with the cast magnesium alloy layer 3, and the dovetail ribs II 2-1 and dovet...

Embodiment 2

[0040] A method for preparing a medical degradable magnesium-zinc-magnesium composite rod with osteoinductive activity, comprising the following steps:

[0041] (1) Preparation of magnesium alloy melt

[0042] 1) Alloy ingredients: The chemical composition is calculated by mass percentage: Cu 2.2%, Ag 1.5%, Sr 1.2%, Ca 2.2%, Y 0.5%, La 1.0%, and the balance is Mg.

[0043] 2) Put the prepared raw materials into the non-consumable electrode water-cooled copper crucible electric arc furnace, and evacuate the furnace to 8.5×10 -4 Pa, pass in argon gas with a purity of 99.99% for 3 times of repeated gas scrubbing, smelting with electricity, the temperature is 750°C, and the holding time is 60 minutes.

[0044] (2) Preparation of deformed magnesium alloy layer

[0045] The magnesium alloy melt is poured into an ingot, and then the ingot is turned over 180° and remelted 5 times to ensure the uniformity of the composition; then the ingot is homogenized, and the homogenization treat...

Embodiment 3

[0071] A method for preparing a medical degradable magnesium-zinc-magnesium composite rod with osteoinductive activity, comprising the following steps:

[0072] (1) Preparation of magnesium alloy melt

[0073] 1) Alloy ingredients: The chemical composition is calculated by mass percentage: Cu 2.5%, Ag 1.8%, Sr 1.4%, Ca 2.6%, Y 0.9%, La 1.2%, and the balance is Mg.

[0074] 2) Put the prepared raw materials into the non-consumable electrode water-cooled copper crucible electric arc furnace, and evacuate the furnace to 8.5×10 -4 Pa, pass in argon gas with a purity of 99.99% for 3 times of repeated gas scrubbing, smelting with electricity, the temperature is 750°C, and the holding time is 60 minutes.

[0075] (2) Preparation of deformed magnesium alloy layer

[0076] The magnesium alloy melt is poured into an ingot, and then the ingot is turned over 180° and remelted 5 times to ensure the uniformity of the composition; then the ingot is homogenized, and the homogenization treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com