Furan resin material based on multi-arm cross-linking agent and starch nanocrystal modification and preparation method and application thereof

A technology of starch nanocrystals and furan resin, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of low corrosion rate, acid fluid damage failure, etc., achieve high strength, increase cross-linked network density, Effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

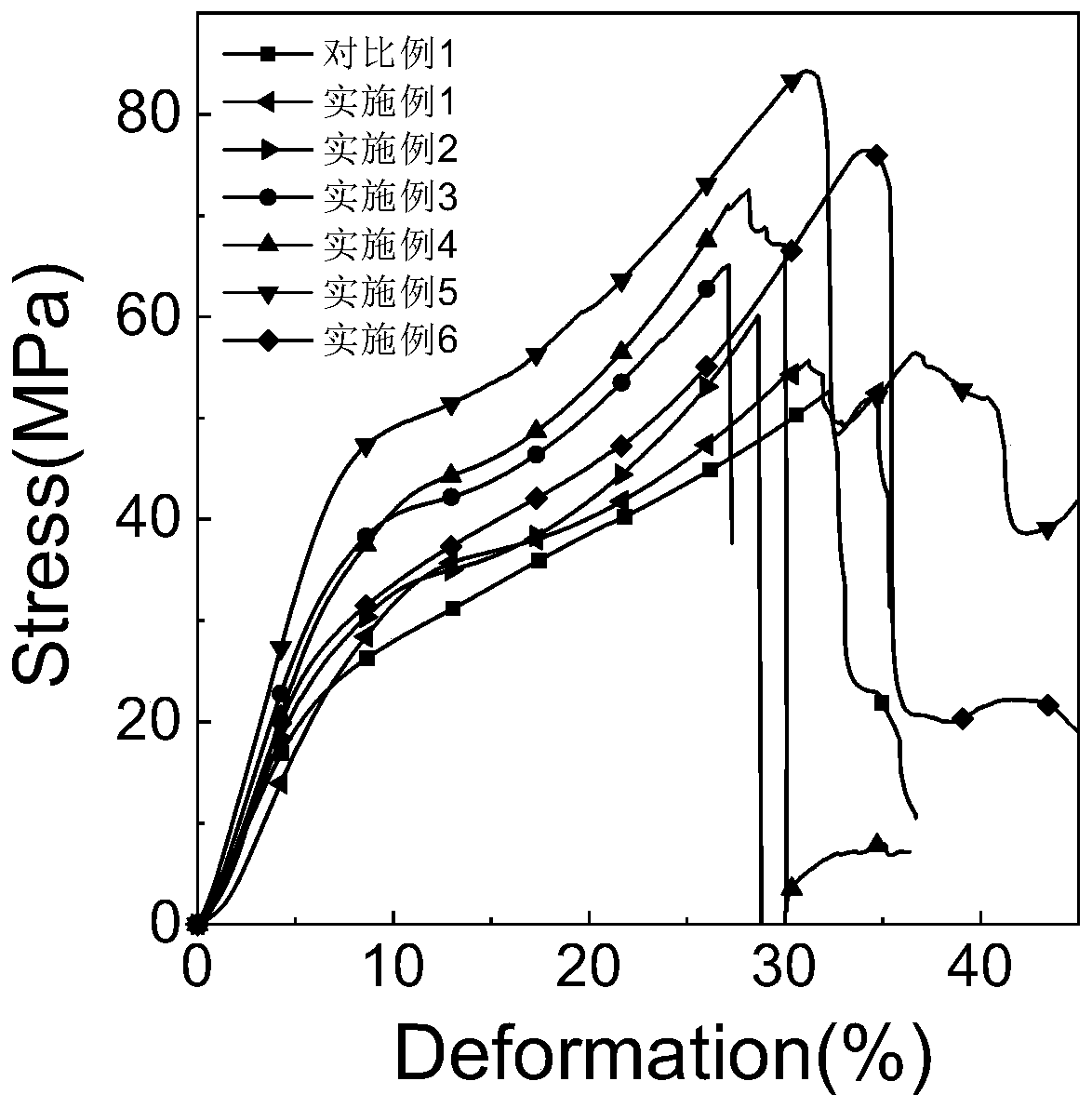

Examples

Embodiment 1

[0032] Embodiment 1 is the furan resin material that contains starch nanocrystal modification, comprises following component, and each component is respectively according to weight part:

[0033] 90 parts by weight of urea-formaldehyde furan resin;

[0034] 10 parts by weight of toluenesulfonic acid;

[0035] 2 parts by weight of starch nanocrystals;

[0036] The preparation process of this kind of furan resin material based on multi-arm crosslinking agent and starch nanocrystal modification is as follows:

[0037] (1) urea-formaldehyde furan resin is mixed with starch nanocrystals and stirred evenly;

[0038] (2) add toluenesulfonic acid, stir;

[0039] (3) Seal the material, place it in an oven with a temperature of 70° C., and react for 8 hours to obtain a furan resin material modified with high-strength starch nanocrystals.

[0040] Let the mixed material after stirring evenly stand for a period of time (no air bubbles are required), then pour it into a compression mol...

Embodiment 2

[0042] Embodiment 2 is the furan resin material containing multi-arm crosslinking agent modification, comprises following components, and each component is respectively according to weight part:

[0043] 85 parts by weight of urea-formaldehyde furan resin;

[0044] 15 parts by weight of toluenesulfonic acid;

[0045] 2 parts by weight of tetrakis (3-mercaptopropionic acid) pentaerythritol ester;

[0046] The preparation process of the furan resin material based on multi-arm crosslinking agent and starch nanocrystal modification includes:

[0047] (1) urea-formaldehyde furan resin is mixed with tetrakis (3-mercaptopropionic acid) pentaerythritol ester, stirred evenly;

[0048] (2) add toluenesulfonic acid, stir;

[0049] (3) Seal the material, place it in an oven at a temperature of 70° C., and react for 6 hours to obtain a high-strength multi-arm crosslinking agent-modified furan resin material.

[0050] The compression sample preparation process and testing process are al...

Embodiment 3

[0052] Embodiment 3 is the furan resin material containing multi-arm cross-linking agent and starch nanocrystal modification, comprises following components, and each component is respectively according to weight part:

[0053]

[0054] The preparation process of this kind of furan resin material based on multi-arm crosslinking agent and starch nanocrystal modification is as follows:

[0055] (1) urea-formaldehyde furan resin is mixed with tetrakis (3-mercaptopropionic acid) pentaerythritol ester, stirred evenly;

[0056] (2) Add starch nanocrystals and stir evenly;

[0057] (3) add toluenesulfonic acid, stir;

[0058] (4) Seal the material, place it in an oven at a temperature of 70° C., and react for 8 hours to obtain a furan resin material modified by a high-strength multi-arm crosslinking agent and starch nanocrystals.

[0059] The compression sample preparation process and testing process are all the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com