a cdin 2 the s 4 Nanoparticles/bivo 4 Preparation method and application of nanorod composite structure

A nanoparticle and composite structure technology, applied in chemical instruments and methods, water/sludge/sewage treatment, chemical/physical processes, etc., can solve undiscovered problems, achieve mild and easy-to-control reaction conditions, and high TOC removal rate , Improve the effect of electron transport ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

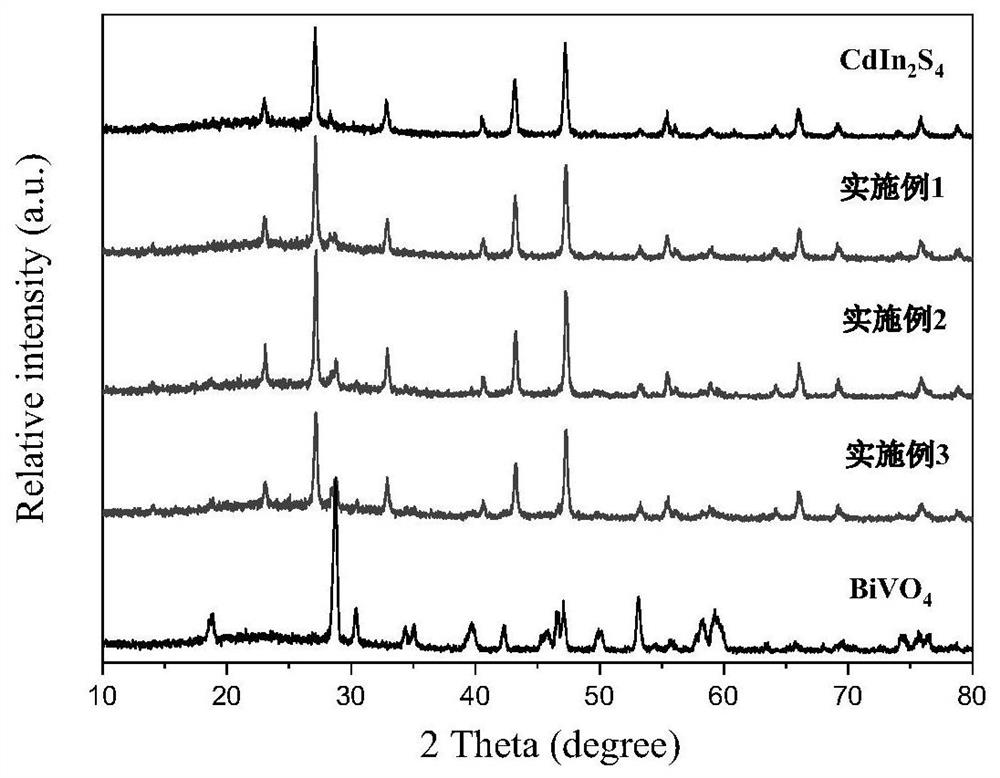

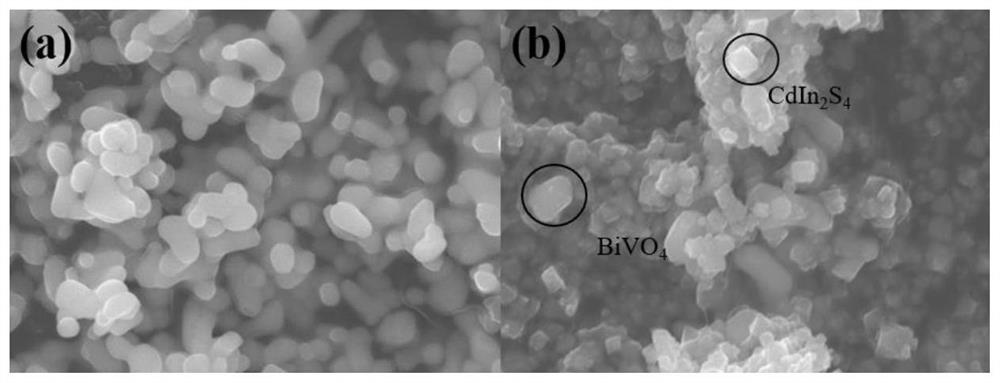

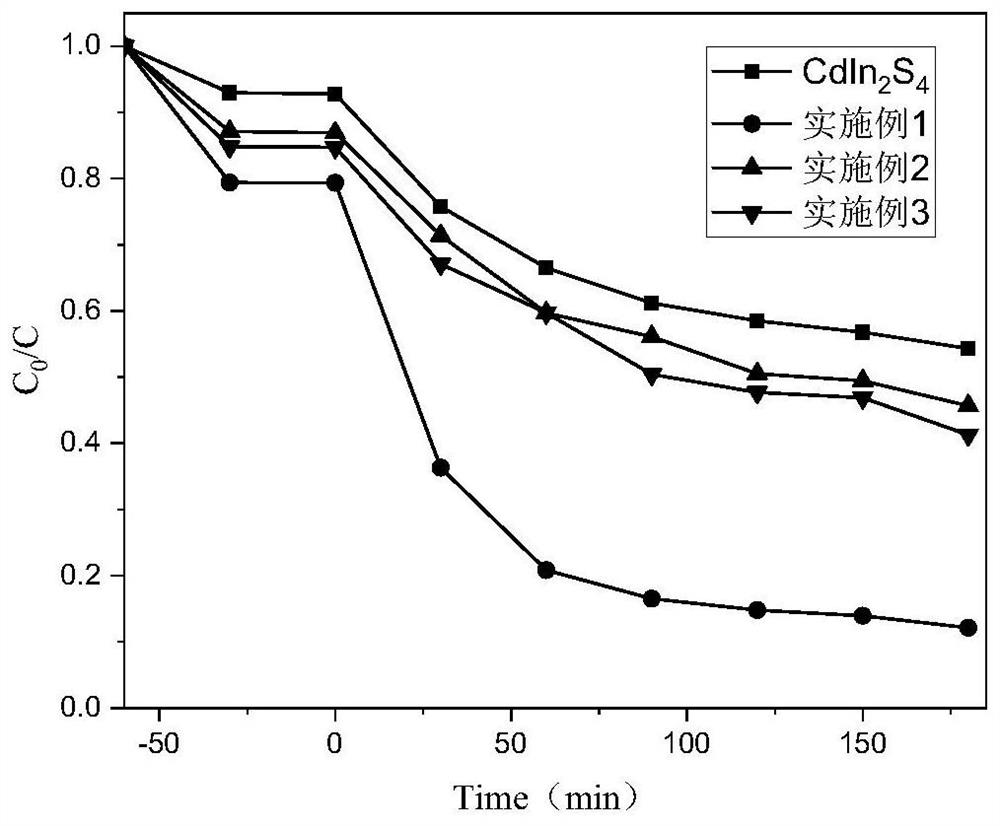

Embodiment 1

[0036] (1) Weigh Bi(NO 3 ) 3 ·5H 2 O, PVP, NaVO 3 , the Bi(NO 3 ) 3 ·5H 2 Add O and PVP into 25mL ethanol, and ultrasonically disperse for 20min to obtain a uniform dispersion A;

[0037] Measure 15mL of water, add NaVO 3 , Ultrasound 10min to obtain dispersion B.

[0038] Slowly add B to A dropwise, stir for 30 minutes, transfer to a hydrothermal kettle for 16 hours at 140°C, wait for it to cool down to room temperature naturally, wash, dry and grind, put the ground sample into a tube furnace for calcination , where the heating rate is 3°C / min, the calcination temperature is 450°C, and the calcination time is 1h, and the BiVO 4 Nano stave.

[0039] (2) BiVO obtained in step (1) 4 0.5mmol of nanorods (mass 0.1620g) were dispersed in a mixed solvent of 15mL of methanol and 15mL of water, sonicated for 10min, stirred for 10min, and sonicated and stirred for 3 times to obtain uniformly dispersed BiVO 4 nanorod suspension;

[0040] 3.0772g CdIn 2 S 4 Nanoparticles di...

Embodiment 2

[0047] (1) Weigh Bi(NO 3 ) 3 ·5H 2 O, PVP, NaVO 3 , the Bi(NO 3 ) 3 ·5H 2 O. PVP was added to 50mL ethanol, and ultrasonically dispersed for 30min to obtain a uniform dispersion A;

[0048] Measure 30mL of water, add NaVO 3 , Ultrasound 15min to obtain dispersion B.

[0049] Slowly add B to A dropwise, after stirring for 30 minutes, transfer to a hydrothermal kettle to react at 160°C for 12 hours, wait for it to cool down to room temperature naturally, wash, dry and grind, and put the ground sample into a tube furnace for Calcination, where the heating rate is 3°C / min, the calcination temperature is 400°C, and the calcination time is 3h, the BiVO 4 Nano stave.

[0050] (2) BiVO obtained in step (1) 4 1.0mmol of nanorods (0.3240g in mass) were dispersed in a mixed solvent of 45mL of methanol and 30mL of water, sonicated for 10min, stirred for 10min, repeated sonication and agitated 5 times, and uniformly dispersed BiVO 4 nanorod suspension;

[0051] 2.9160g CdIn 2 ...

Embodiment 3

[0056] (1) Weigh Bi(NO 3 ) 3 ·5H 2 O, PVP, NaVO 3 , the Bi(NO 3 ) 3 ·5H 2 O. PVP was added to 75mL ethanol, and ultrasonically dispersed for 40 minutes to obtain a uniform dispersion A;

[0057] Measure 45mL of water, add NaVO 3 , Ultrasound 20min to obtain dispersion B.

[0058] Slowly add B to A dropwise, after stirring for 40 minutes, transfer to a hydrothermal kettle to react at 180°C for 8 hours, wait for it to cool down to room temperature naturally, wash, dry and grind, and put the ground sample into a tube furnace for Calcination, where the heating rate is 1.5°C / min, the calcination temperature is 480°C, and the calcination time is 2h, and the BiVO 4 Nano stave.

[0059] (2) BiVO obtained in step (1) 4 1.5mmol of nanorods (mass 0.4860g) were dispersed in a mixed solvent of 45mL of methanol and 45mL of water, ultrasonicated for 20min, stirred for 20min, repeated ultrasonicated and stirred for 6 times, and uniformly dispersed BiVO 4 nanorod suspension;

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com