Bismuth tungstate/bismuth sulfide/molybdenum disulfide heterojunction ternary composite material and preparation method and application thereof

A technology of molybdenum disulfide and composite materials, applied in chemical instruments and methods, physical/chemical process catalysts, water treatment of special compounds, etc., can solve problems such as low photocatalytic efficiency and weak surface adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

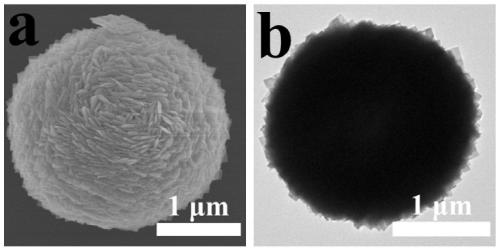

[0037] (1) Spherical Bi 2 WO 6 preparation of

[0038] In spherical Bi 2 WO 6 In the synthesis of the precursor, solution A and solution B were prepared. Solution A, 2mmol Bi(NO 3 ) 3 ·5H 2 O and 4g of PVP K30 were added to a mixed solution of 50mL of water, absolute ethanol, and glacial acetic acid (3:1:1 by volume), and stirred at room temperature until the solution was clear. Solution B, in 20mL H 2 Add 1mmol Na to O 2 WO 4 2H 2 O, ultrasound for 30 minutes. Then add solution B dropwise to solution A, stir for 60 minutes to obtain a uniform suspension, transfer it to a 100mL polytetrafluoroethylene-lined autoclave, react with solvent heat at 180°C for 18 hours, and cool to room temperature naturally , through centrifugation, washing, drying, and grinding, the pale yellow Bi 2 WO 6 powder.

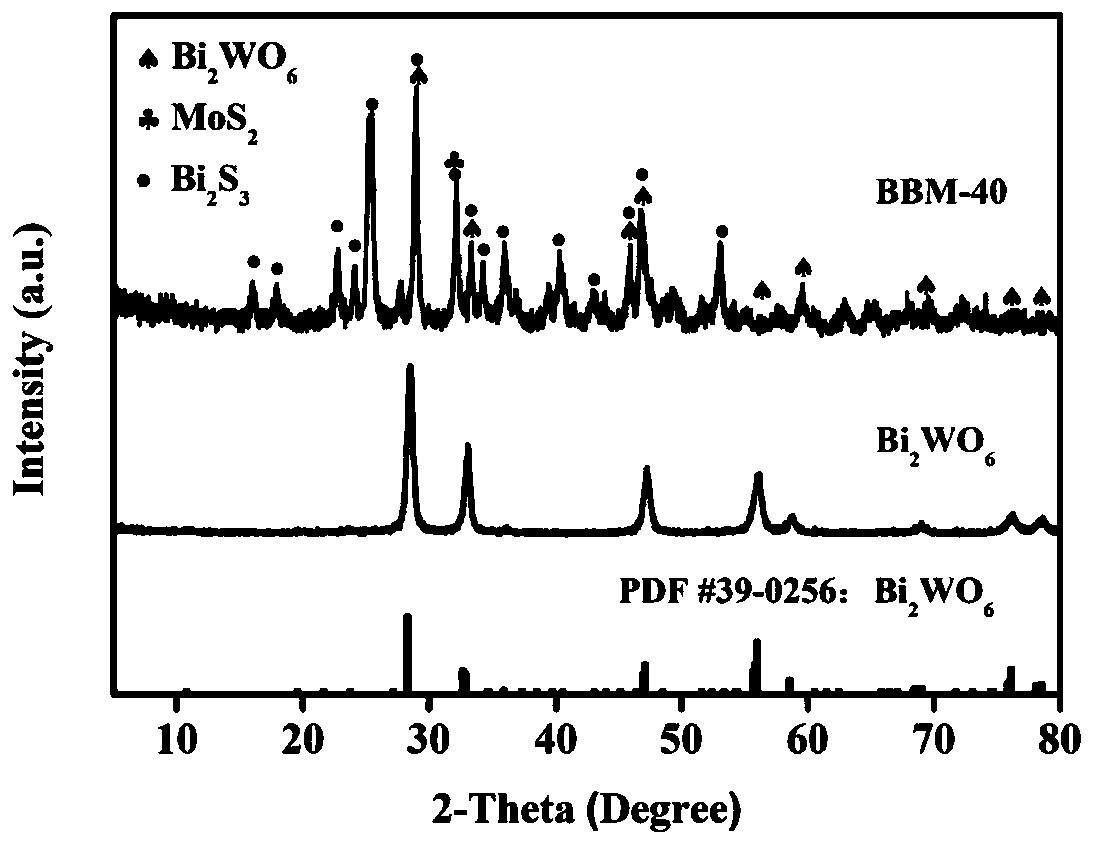

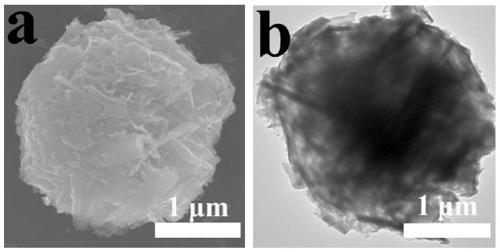

[0039] (2) Spherical Bi 2 WO 6 / Bi 2 S 3 / MoS 2 Preparation of heterojunction ternary composites

[0040] 200mg Bi 2 WO 6 Disperse the powder into 40mL water, add ...

Embodiment 2

[0042] (1) Spherical Bi 2 WO 6 preparation of

[0043] In spherical Bi 2 WO 6 In the synthesis of the precursor, solution A and solution B were prepared. Solution A, 2mmol Bi(NO 3 ) 3 ·5H 2 O and 4g of PVP K30 were added to a mixed solution of 50mL of water, absolute ethanol, and glacial acetic acid (3:1:1 by volume), and stirred at room temperature until the solution was clear. Solution B, in 20mL H 2 Add 1mmol Na to O 2 WO 4 2H 2 O, ultrasound for 30 minutes. Then add solution B dropwise to solution A, stir for 60 minutes to obtain a uniform suspension, transfer it to a 100mL polytetrafluoroethylene-lined autoclave, react with solvent heat at 180°C for 18 hours, and cool to room temperature naturally , through centrifugation, washing, drying, and grinding, the pale yellow Bi 2 WO 6 powder.

[0044] (2) Spherical Bi 2 WO 6 / Bi 2 S 3 / MoS 2 Preparation of heterojunction ternary composites

[0045] 200mg Bi 2 WO 6 Disperse the powder into 40mL water, add ...

Embodiment 3

[0047] (1) Spherical Bi 2 WO 6 preparation of

[0048] In spherical Bi 2 WO 6 In the synthesis of the precursor, solution A and solution B were prepared. Solution A, 2mmol Bi(NO 3 ) 3 ·5H 2 O and 4g of PVP K30 were added to a mixed solution of 50mL of water, absolute ethanol, and glacial acetic acid (3:1:1 by volume), and stirred at room temperature until the solution was clear. Solution B, in 20mL H 2 Add 1mmol Na to O 2 WO 4 2H 2 O, ultrasound for 30 minutes. Then add solution B dropwise to solution A, stir for 60 minutes to obtain a uniform suspension, transfer it to a 100mL polytetrafluoroethylene-lined autoclave, react with solvent heat at 180°C for 18 hours, and cool to room temperature naturally , through centrifugation, washing, drying, and grinding, the pale yellow Bi 2 WO 6 powder.

[0049] (2) Spherical Bi 2 WO 6 / Bi 2 S 3 / MoS 2 Preparation of heterojunction ternary composites

[0050] 200mg Bi 2 WO 6 Disperse the powder into 40mL water, add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com