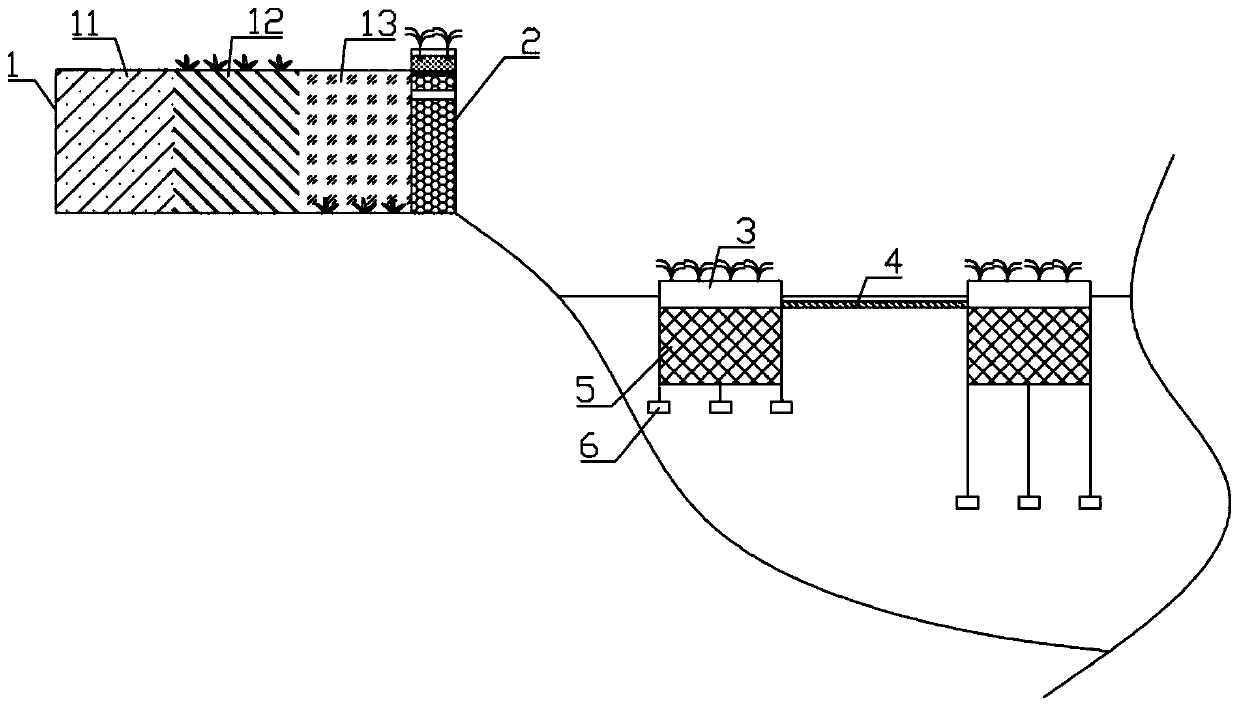

In-situ pretreatment system suitable for water body from lake type water source

A water source and pretreatment technology, applied in the field of water treatment, can solve problems such as long treatment time, secondary pollution, and little involvement, and achieve the effects of reducing the amount of sediment, preventing pollution, and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

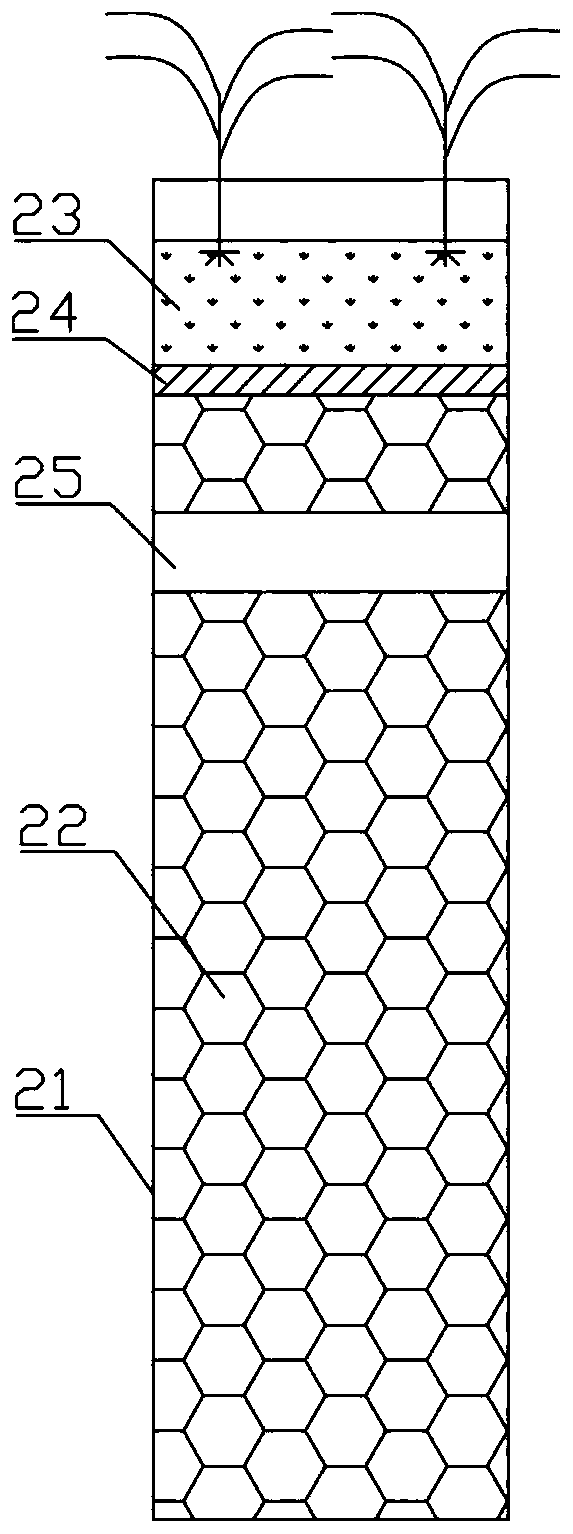

[0042] Embodiment 1 Preparation of filter packing 1

[0043] Weigh 8 parts of bentonite, 6 parts of zeolite, 3 parts of coconut peat, 5 parts of peat soil, 1 part of sepiolite, and 3 parts of cement, stir and mix evenly, dry at 60°C for 3 hours, then ball mill, pass through a 100-mesh sieve, and add Add 20 parts of acrylic resin, then add 20 parts of water and stir to obtain a viscous mixed emulsion, then air into the mixed emulsion in the form of pulses of 5s and 30s intermittently, according to the flow rate of 0.1L / min, while stirring vigorously, to A large number of uniform bubbles appear in the mixed emulsion, immediately add the modified ceramsite according to the solid-liquid ratio of 1g / ml, stir slowly for 1min, remove it, and maintain it at 15°C until the water-retaining layer on the surface of the modified ceramsite is semi-solidified. Apply ultrasonic treatment with a frequency of 25KHz and a power of 120W for 30s. After an interval of 2 minutes, ultrasonic treatmen...

Embodiment 2

[0044] Embodiment 2 Preparation of filter packing 2

[0045] Weigh 5 parts of bentonite, 10 parts of zeolite, 5 parts of coconut peat, 3 parts of peat soil, 2 parts of sepiolite, and 2 parts of cement, stir and mix evenly, dry at 60°C for 3 hours, then ball mill, pass through a 100-mesh sieve, and add Add 15 parts of acrylic resin, then add 20 parts of water and stir to obtain a viscous mixed emulsion, then air into the mixed emulsion in the form of pulses of 5s and 30s intermittently, according to the flow rate of 0.1L / min, while stirring vigorously, until A large number of uniform bubbles appear in the mixed emulsion, immediately add the modified ceramsite according to the solid-liquid ratio of 1g / ml, stir slowly for 1min, remove it, and maintain it at 15°C until the water-retaining layer on the surface of the modified ceramsite is semi-solidified. Apply ultrasonic treatment with a frequency of 25KHz and a power of 120W for 30s. After an interval of 2 minutes, ultrasonic tre...

Embodiment 3

[0046] Embodiment 3 Preparation of filter filler 3

[0047] Weigh 10 parts of bentonite, 5 parts of zeolite, 1 part of coconut peat, 8 parts of peat soil, 1 part of sepiolite, and 5 parts of cement, stir and mix evenly, dry at 60°C for 3 hours, then ball mill, pass through a 100-mesh sieve, and add Add 30 parts of acrylic resin, then add 20 parts of water and stir to obtain a viscous mixed emulsion, then air into the mixed emulsion in the form of pulses of 5s and 30s intermittently, according to the flow rate of 0.1L / min, while stirring vigorously, to A large number of uniform bubbles appear in the mixed emulsion, immediately add the modified ceramsite according to the solid-liquid ratio of 1g / ml, stir slowly for 1min, remove it, and maintain it at 15°C until the water-retaining layer on the surface of the modified ceramsite is semi-solidified. Apply ultrasonic treatment with a frequency of 25KHz and a power of 120W for 30s. After an interval of 2 minutes, ultrasonic treatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com