Method for preparing scandium-zirconium powder through spray pyrolysis and scandium-zirconium powder prepared through method

A technology of spray pyrolysis and zirconium powder, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, fuel cells, etc., can solve problems such as uneven distribution, high raw material cost, and complicated operation, and achieve uniform composition and low raw material cost , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

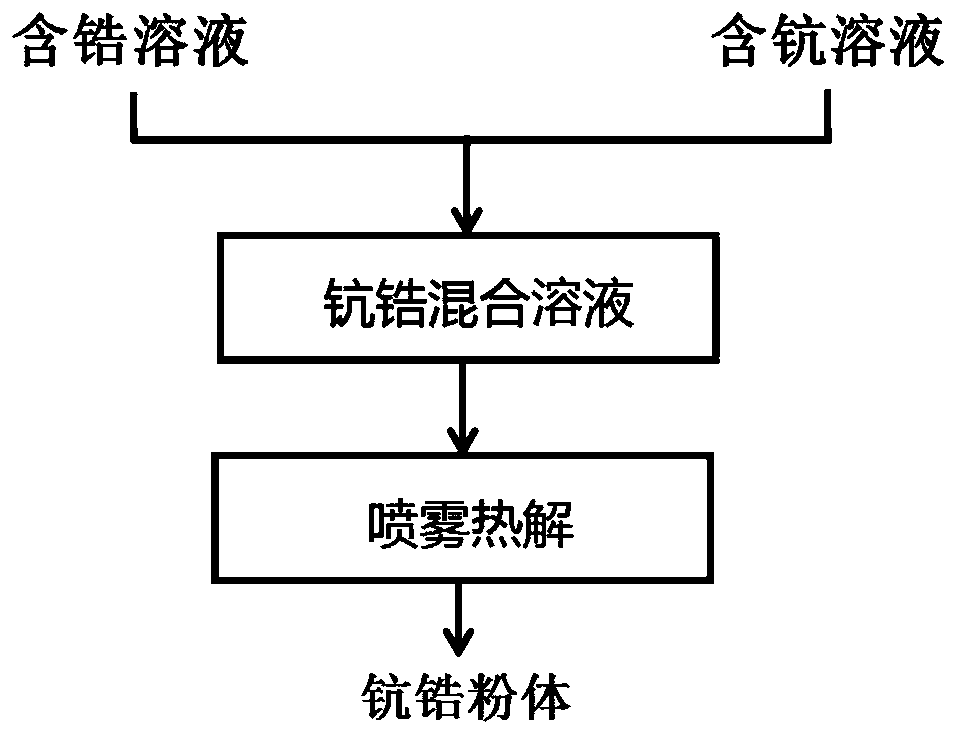

[0029] Mix the scandium nitrate aqueous solution and the zirconium nitrate aqueous solution to obtain the scandium-zirconium mixed solution; atomize the scandium-zirconium mixed solution into fine droplets, and bring them into the high-temperature reaction furnace through the flow of carrier gas. Within a short period of time, the steps of solvent evaporation, solute precipitation, drying, metal salt thermal decomposition and sintering molding are successively formed, and finally scandium-zirconium powder is formed. Wherein, the concentration of cations in the mixed solution of scandium and zirconium is 0.5 mol / L, and the number of moles of scandium ions is 8% of the total number of moles of scandium ions and zirconium ions. The ultrasonic nozzle power is 30W, the carrier gas flow rate is 30L / min, and the spray pyrolysis temperature is 1200°C.

Embodiment 2

[0031] Mix the scandium chloride aqueous solution and the zirconium oxychloride aqueous solution to obtain the scandium-zirconium mixed solution; atomize the scandium-zirconium mixed solution into fine droplets, and bring them into the high-temperature reaction furnace through the flow of carrier gas. After the droplets enter the reaction furnace, In a relatively short period of time, the steps of solvent evaporation, solute precipitation, drying, metal salt thermal decomposition and sintering molding are successively formed, and finally scandium-zirconium powder is formed. Wherein, the concentration of cations in the mixed solution of scandium and zirconium is 5 mol / L, and the number of moles of scandium ions is 10% of the total number of moles of scandium ions and zirconium ions. The ultrasonic nozzle power is 15W, the carrier gas flow rate is 20L / min, and the spray pyrolysis temperature is 1400°C.

Embodiment 3

[0033] Mix the scandium chloride aqueous solution and the zirconium oxychloride aqueous solution to obtain the scandium-zirconium mixed solution; atomize the scandium-zirconium mixed solution into fine droplets, and bring them into the high-temperature reaction furnace through the flow of carrier gas. After the droplets enter the reaction furnace, In a relatively short period of time, the steps of solvent evaporation, solute precipitation, drying, metal salt thermal decomposition and sintering molding are successively formed, and finally scandium-zirconium powder is formed. Wherein, the concentration of cations in the mixed solution of scandium and zirconium is 2 mol / L, and the number of moles of scandium ions is 13% of the total number of moles of scandium ions and zirconium ions. The ultrasonic nozzle power is 10W, the carrier gas flow rate is 10L / min, and the spray pyrolysis temperature is 400°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com